Electronic component separator and method for producing the same

A technology of electronic components and manufacturing methods, applied in the direction of electrical components, battery pack parts, hybrid capacitor separators, etc., can solve problems such as short circuit of electrodes, distance from diaphragm film thickness without any consideration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

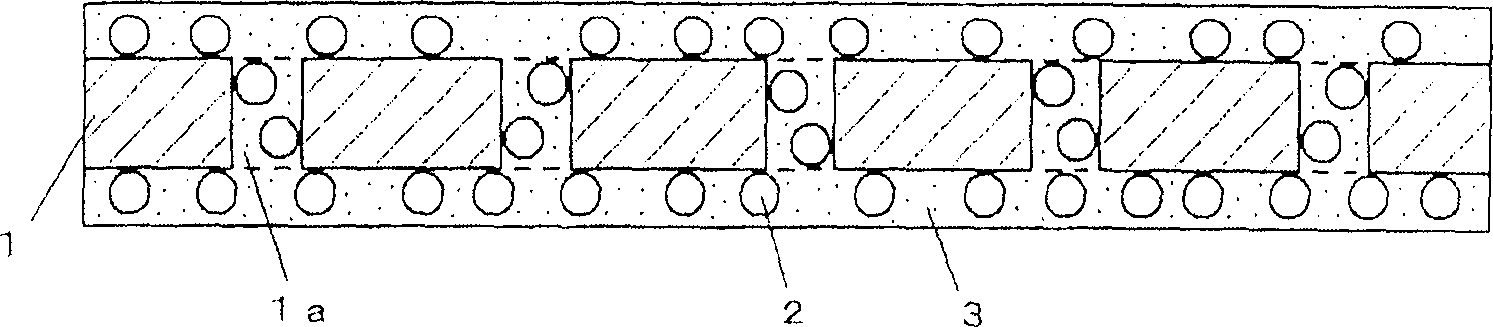

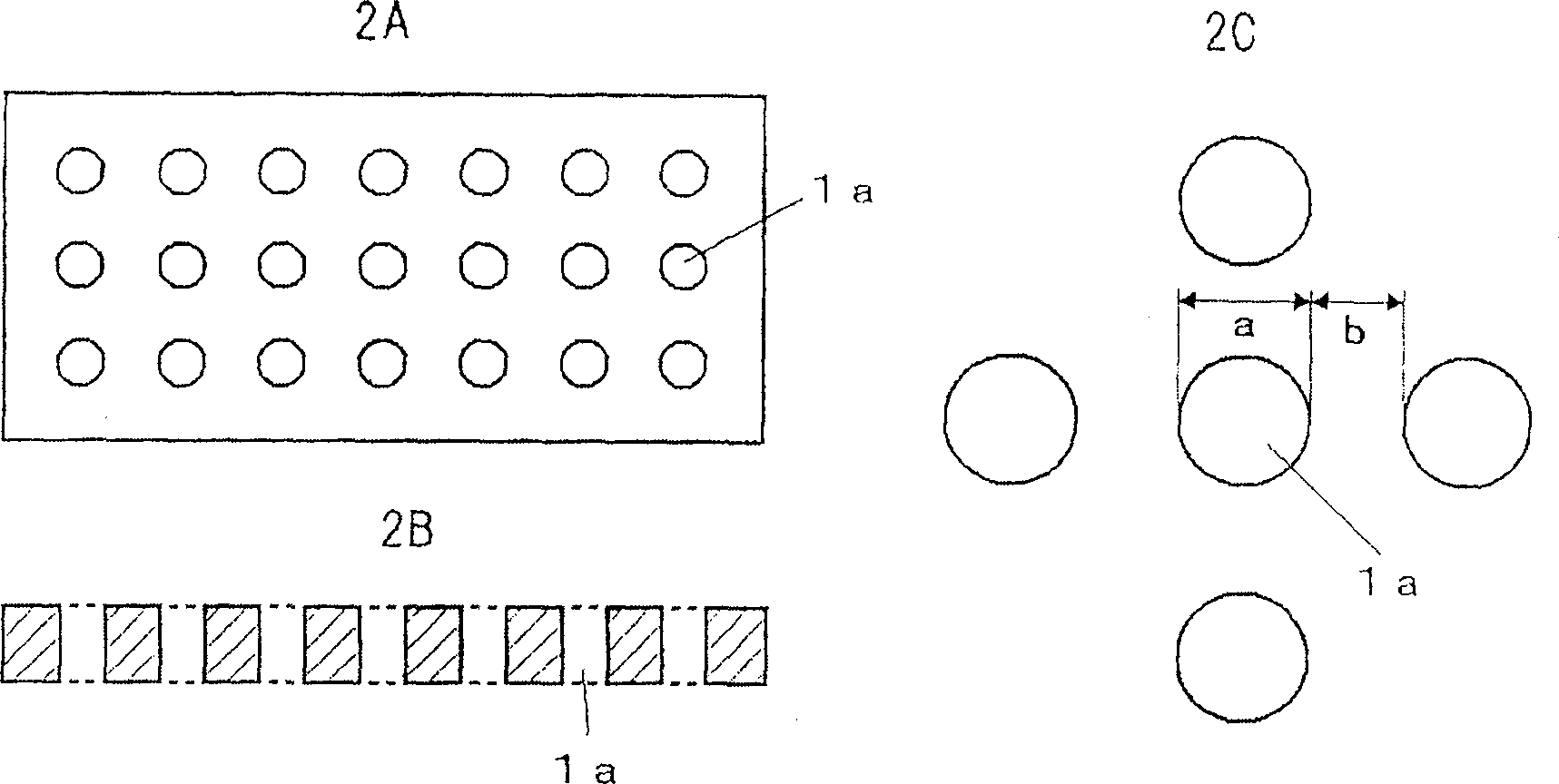

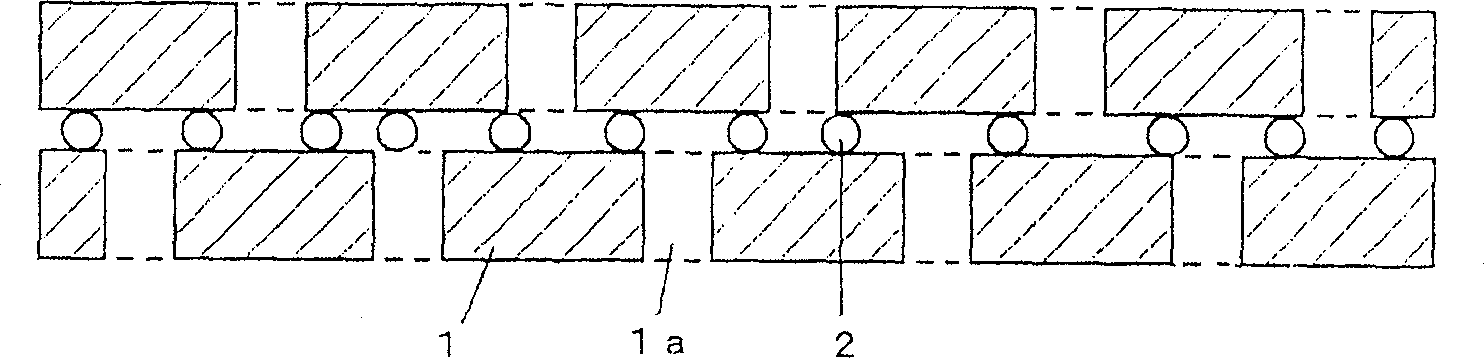

Image

Examples

Embodiment 1

[0074] A vinylidene fluoride homopolymer with a weight average molecular weight of 300,000 is prepared to be dissolved in 1-methyl-2-pyrrolidone, and dibutyl phthalate is added to adjust the vinylidene fluoride homopolymer to a 15% by weight solution . The amount of water contained in this solution measured by the Karl Fischer method was 0.6%. Next, PTFE particles with a primary average particle size of 0.25 μm and a melting point of 320° C. were placed on the surface of a resin film made of polyethylene terephthalate at a rate of 5 g / m. 2 A non-woven fabric with a thickness of 10 μm obtained by supporting only polyethylene terephthalate fibers made of fibers with a melting point of 260°C, and coating the above-mentioned solution on the non-woven fabric by casting method . Next, the solvent in the solution contained in the nonwoven fabric was evaporated by heat to prepare a separator having a thickness of 22 μm in which a porous resin structure made of vinylidene fluoride ho...

Embodiment 2

[0077] In Example 1, a separator for an electronic element was produced in the same manner as in Example 1, except that a nonwoven fabric having a thickness of 15 μm composed only of vinylon fibers having a melting point of 205° C. was used as the porous substrate. When the separator for electronic components is observed with an electron microscope, there are no defects such as pinholes, and the porous resin structure communicates from one side of the porous substrate to the other through the connection of several holes, and the diameter of each hole is smaller than that of the porous substrate. Thickness is small. In addition, no slope of the pore size distribution was observed in the thickness direction of the separator, confirming a homogeneous porous structure in the thickness direction. The pore diameter of the membrane was determined to be 0.8 μm by the bubble point method.

Embodiment 3

[0079] In Example 1, except that the porous substrate is a resin film made of polyethylene terephthalate with a melting point of 200°C, in the vertical direction, only the resin film is used between one side and the other side of the resin film. A separator for electronic components was fabricated in the same manner as in Example 1, except for a 15 μm-thick microporous resin film composed of through-holes without a substantially shielding structure. When the separator for electronic components is observed with an electron microscope, there are no defects such as pinholes, and the porous resin structure is connected and communicated by several holes on one side of the porous substrate to the other side, and the pore diameter of each hole is smaller than that of the microporous porous resin. The thickness of the film is small. In addition, no slope of the pore size distribution was observed in the thickness direction of the separator, confirming a homogeneous porous structure in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com