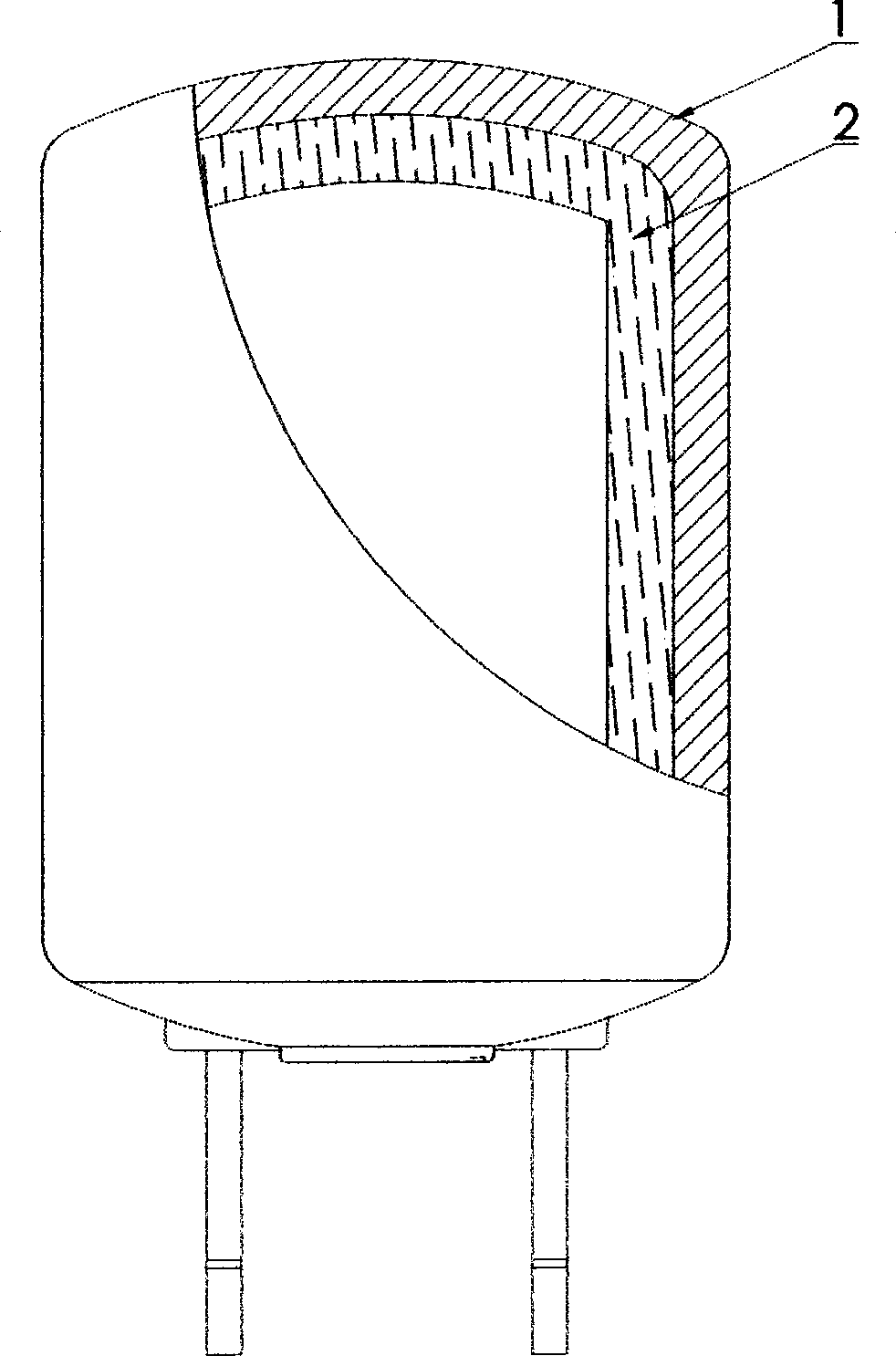

Water heater internal bladder having nano coating

A water heater liner, nano-coating technology, applied in coatings, water heaters, fluid heaters, etc., can solve the problems of inability to guarantee the quality of enamel, porcelain, and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Use 2 mm thick ordinary steel plate or aluminum alloy plate, stainless steel plate, press and weld into 10 electric water heater inner tank blanks. After degreasing, pickling, water washing and other purification treatments are carried out on the inner surface of the body, the electroless nickel-phosphorus alloy layer is then treated.

[0017] The process of electroless plating is to pour the electroless plating solution containing nickel phosphorus into the plating tank in proportion, adjust the pH value of the plating solution to 4.7 with sulfuric acid or ammonia water, and maintain its temperature at 85 ° C, and the above blank Put the body into the plating solution and soak for 60 minutes. As a result, the inner surface is coated with a uniform nickel-phosphorus alloy film. It is measured that the thickness of the coating film is 15 microns, the hardness is HV300, the phosphorus content of the coating film is 10%, and the balance is nickel.

Embodiment 2

[0019] According to the scheme of embodiment 1, there are 10 common steel plates, aluminum alloy plates, and stainless steel inner tank blanks for electric water heaters. Clean the inner surface of the body with No. 60 cleaning solution, air dry, sandblast, clean, dip-coat zinc-chromium coating solution, and cure at 330°C for 40 minutes; spray zinc-chromium coating solution again, and cure at 330°C for 35 minutes. As a result, the inner surface is covered with a uniform layer of zinc-chromium alloy containing complex chromium salt compounds (nCr03.mCr203). The thickness of the coating was measured to be 12 microns.

Embodiment 3

[0021] On 10 inner tanks of electric water heaters with a nickel-phosphorus alloy layer, the inner surface is sprayed with zinc-chromium coating solution, and cured at 330° C. for 35 minutes. The electric water heater liner is made of a nickel-phosphorus alloy layer and a zinc-chromium alloy layer. The thickness of the coating was measured to be 25 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com