Method for preparing magnesia crystal by using temperature control arc furnace

An electric arc furnace and magnesium oxide technology, applied in the field of material science, can solve problems such as poor temperature control ability, and achieve the effects of saving energy, improving output and quality, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

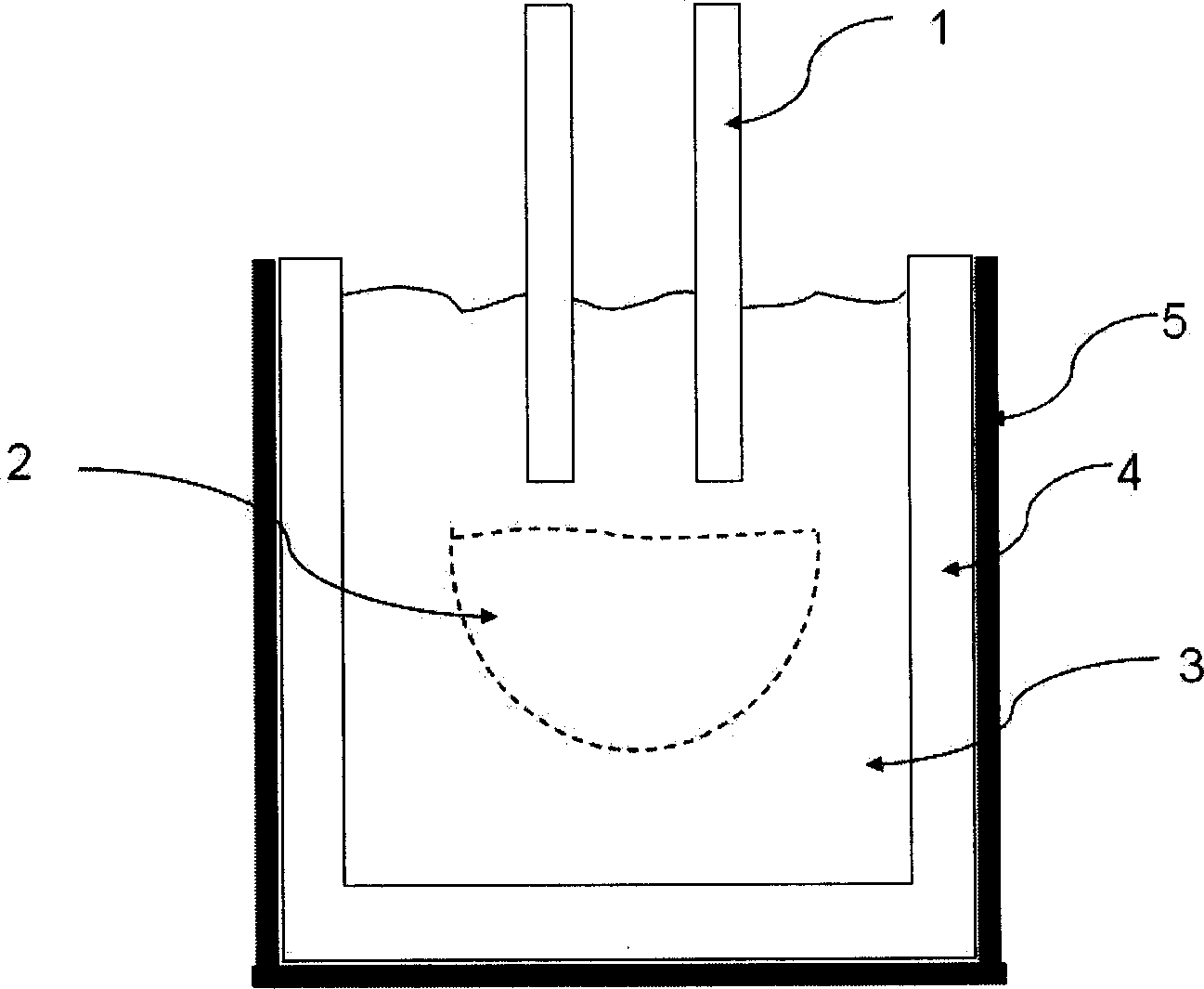

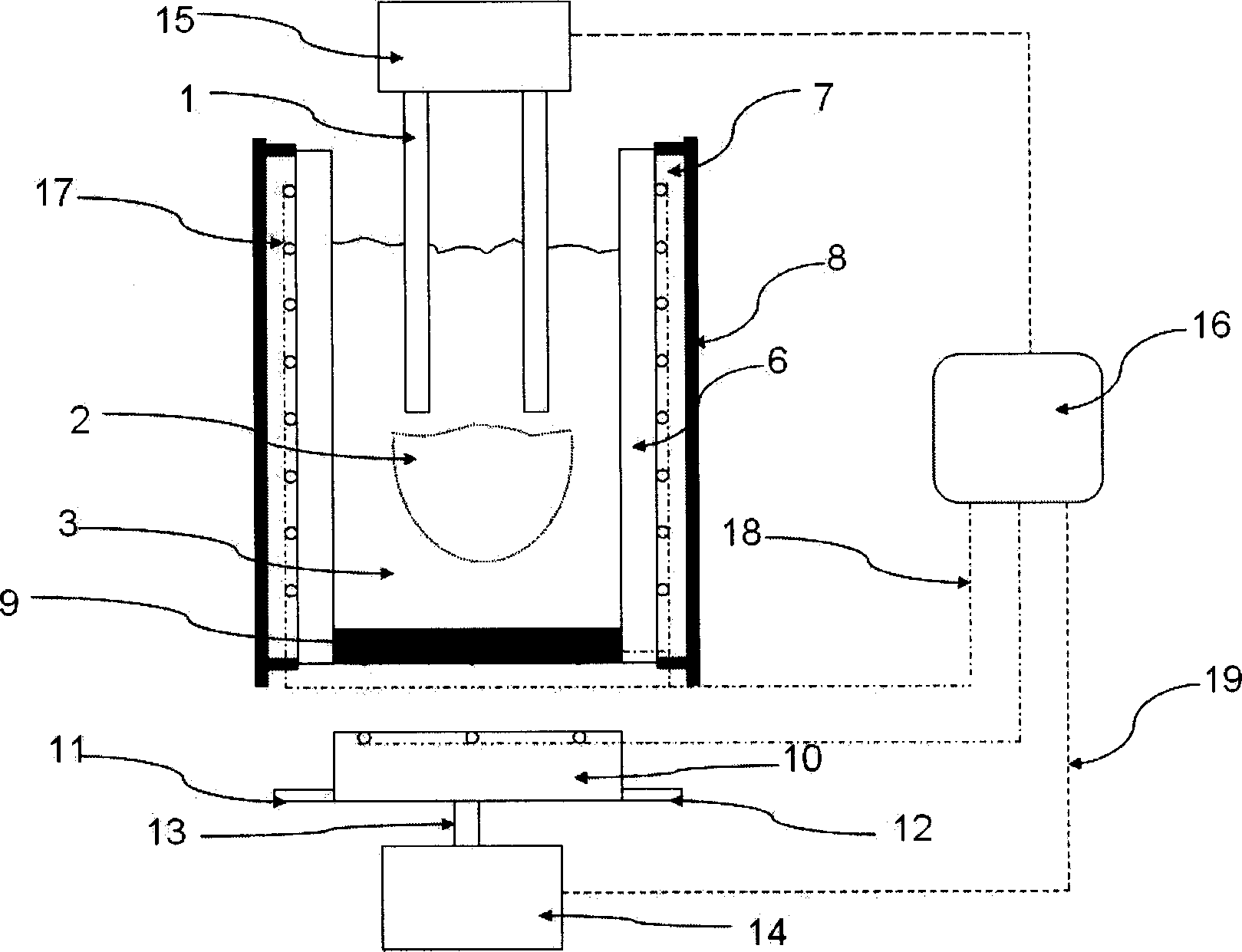

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0019] The specific embodiment of the temperature-controlled electric arc furnace used in the present invention is as follows.

[0020] The side wall of the cylindrical furnace shell is composed of magnesia-carbon bricks as the inner insulation layer 6, and glass fiber reinforced plastic as the outer insulation layer 8, and there is an air gap 7 between the two layers of materials. lost. The metal bottom plate 9 at the bottom of the furnace is a stainless steel plate, and this bottom plate plays the dual role of heat conduction and support. In order to complete the real-time measurement of the temperature field in the furnace, temperature-sensing probes 17 are evenly distributed on the outer surface of the inner insulation layer, the lower surface of the metal bottom plate, and the upper surface of the water cooling device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com