Liquid chlorine directly charging system and apparatus

A liquid chlorine and adding process technology is applied in the field of tap water disinfectant dosing process system, which can solve the problems of high operating costs, solid particle impurities cannot be entrained in the overcurrent working medium, and high power consumption costs, and achieves simple and reliable process equipment. The effect of automatic operation and power consumption cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

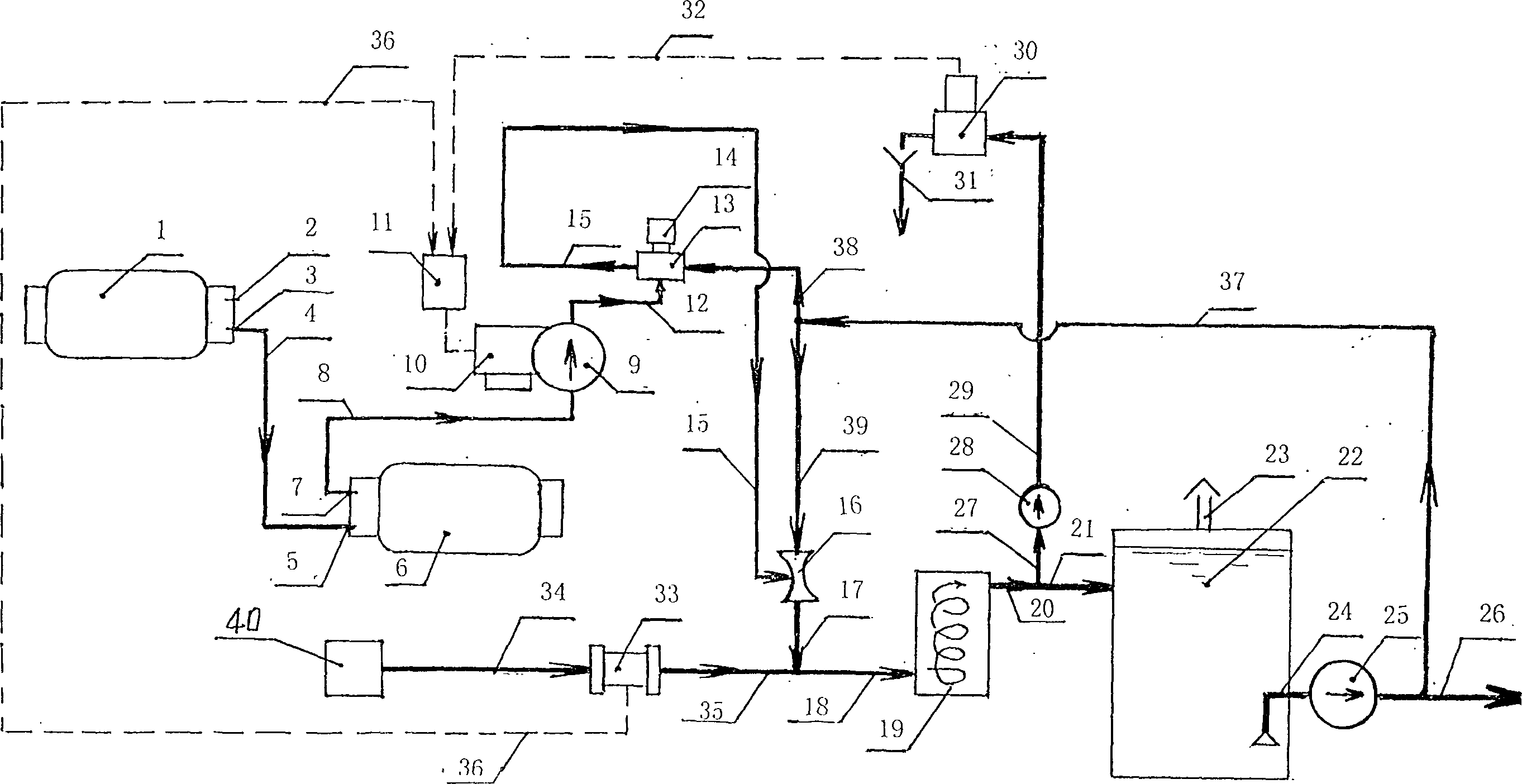

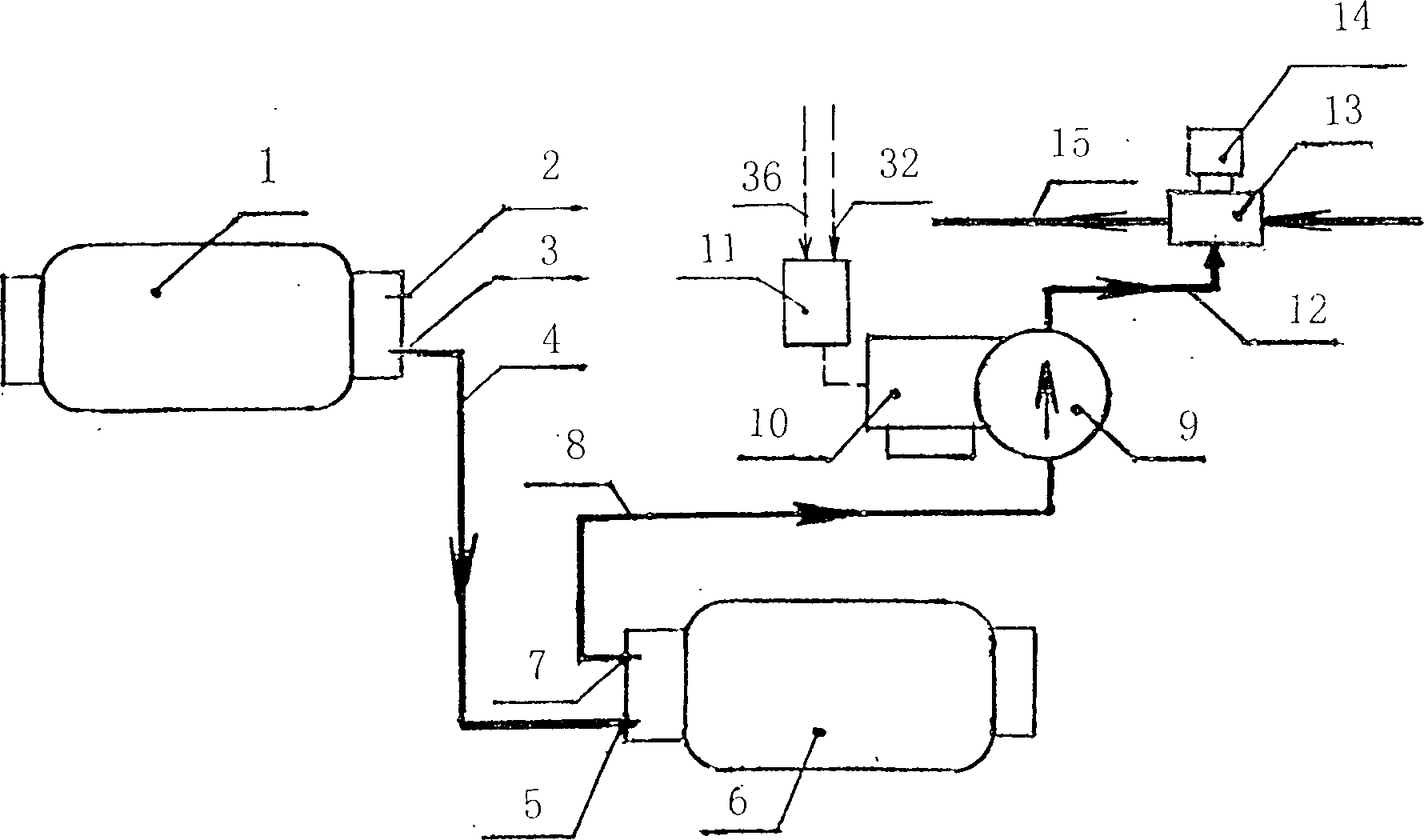

[0045]Embodiment 1: as shown in the figure, the present invention comprises on-line liquid chlorine cylinder 1, and the liquid chlorine in the on-line liquid chlorine cylinder 1 enters liquid chlorine precipitation cylinder 6 through on-line chlorine valve 3, liquid chlorine pipeline 4, chlorine valve 5, through The chlorine valve 7 and the liquid chlorine pipeline 8 enter the metering pump 3. After pressurization and flow control, the liquid chlorine enters the liquid chlorine doser 13 through the pipeline 12, mixes with the pressure water that enters the liquid chlorine doser 13 through the pipeline 38, and After dissolved in water, high-concentration chlorine-containing water is formed, and then enters the water injector 16 through the pipeline 15, and the water injector forms a vacuum so that the chlorine-containing water in the pipeline 15 does not leak out, and enters the water injector 16 with the pipeline 39 The pressure water is further mixed and diluted, and enters th...

Embodiment 2

[0059] Embodiment 2: as shown in the figure, the present invention comprises on-line liquid chlorine cylinder 1, and the liquid chlorine in the on-line liquid chlorine cylinder 1 enters liquid chlorine precipitation steel cylinder 6 through on-line chlorine valve 3, liquid chlorine pipeline 4, chlorine valve 5, through chlorine The valve 7 and the liquid chlorine pipeline 8 enter the metering pump 3. After pressurization and flow control, the liquid chlorine enters the liquid chlorine doser 13 through the pipeline 12 and mixes and dissolves with the pressure water that enters the liquid chlorine doser 13 through the pipeline 38. After entering the water, high-concentration chlorine-containing water is formed, and then enters the water injector 16 through the pipeline 15, and the water injector forms a vacuum so that the chlorine-containing water in the pipeline 15 does not leak out, and the chlorine-containing water in the pipeline 39 enters the water injector 16. The pressure ...

Embodiment 3

[0061]Embodiment 3: As shown in the figure, the present invention includes Embodiment 2: As shown in the figure, the present invention includes an online liquid chlorine steel cylinder 1, and the liquid chlorine in the online liquid chlorine steel cylinder 1 passes through an online chlorine valve 3 and a liquid chlorine pipeline 4 , chlorine valve 5 enters liquid chlorine precipitation cylinder 6, enters metering pump 3 through chlorine valve 7, liquid chlorine pipeline 8, after pressurization and flow control, liquid chlorine enters liquid chlorine doser 13 through pipeline 12, and through pipeline 38 After the pressurized water entering the liquid chlorine doser 13 is mixed and dissolved into the water, high-concentration chlorine-containing water is formed, and then enters the water injector 16 through the pipeline 15, and the water injector forms a vacuum, so that the chlorine-containing water in the pipeline 15 does not Leakage, further mixing and dilution with the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com