Adhesive for sealing organic electroluminescent element and use thereof

An electroluminescent element and sealing technology, applied in electroluminescent light sources, electrical components, adhesives, etc., can solve the problems of increased residual stress, insufficient curing of photocurable adhesives, and reduced component performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~2

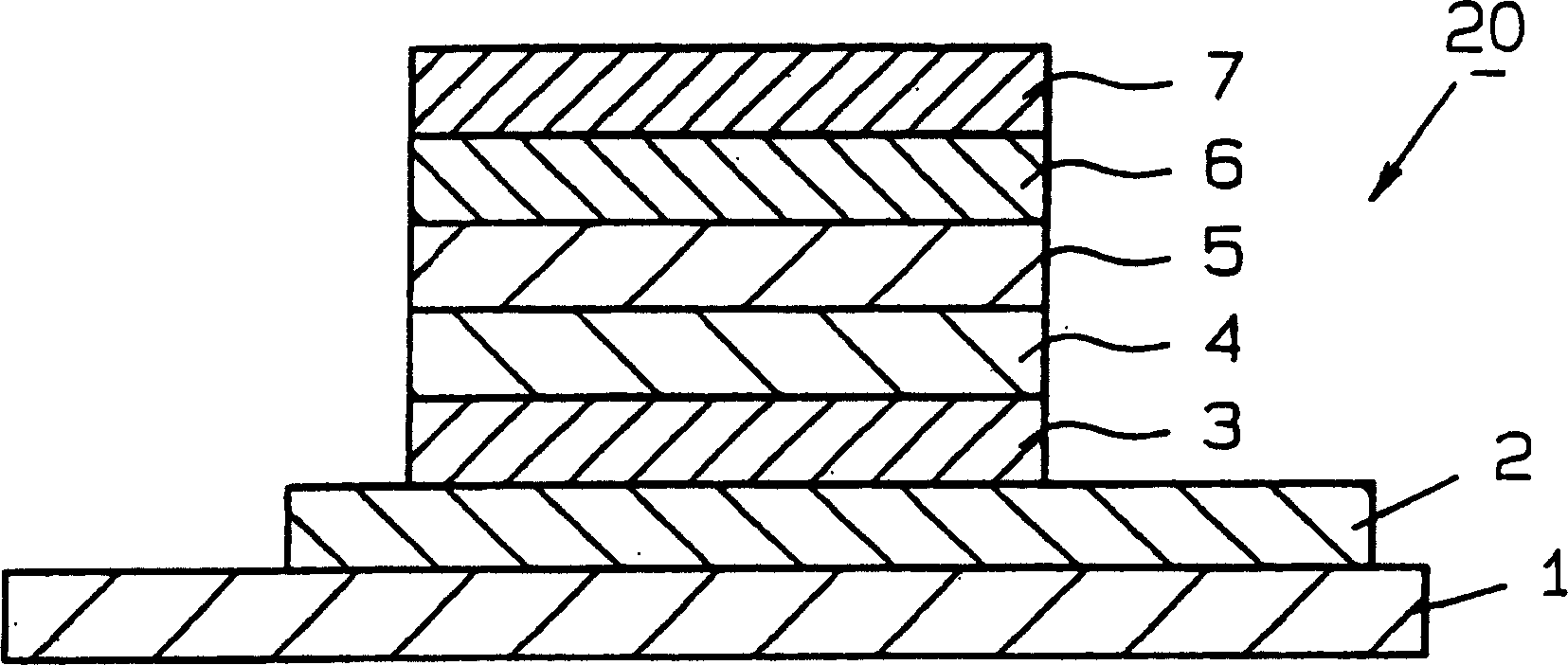

[0119] (1) Preparation of organic EL element substrate 1

[0120] An ITO electrode film was formed to a thickness of 1000 Å on a glass substrate (25 mm×25 mm×0.7 mm), and the formed member was used as a transparent supporting substrate. Use acetone, alkaline aqueous solution, ion-exchanged water, and isopropanol to carry out ultrasonic cleaning to the above-mentioned transparent support substrate for 15 minutes respectively, then clean with boiling isopropanol for 10 minutes, and then use a UV-ozone cleaner (NL-UV253, Japan Laser Electronics Co., Ltd.) for pretreatment. Next, fix the transparent support substrate on the substrate holder of the vacuum evaporation device, put N, N'-bis(1-naphthyl)-N, N'-diphenylbenzidine (α -NPD) 200mg, put tris(8-hydroxyquinoline) aluminum (Alq3) 200mg in other bisque crucible, reduce the pressure in the vacuum chamber to 1×10 -4 Pa. Then, the crucible containing α-NPD was heated, and α-NPD was deposited on the substrate at a deposition rate...

Embodiment 4~9

[0139] (Examples 4-9, Comparative Example 3)

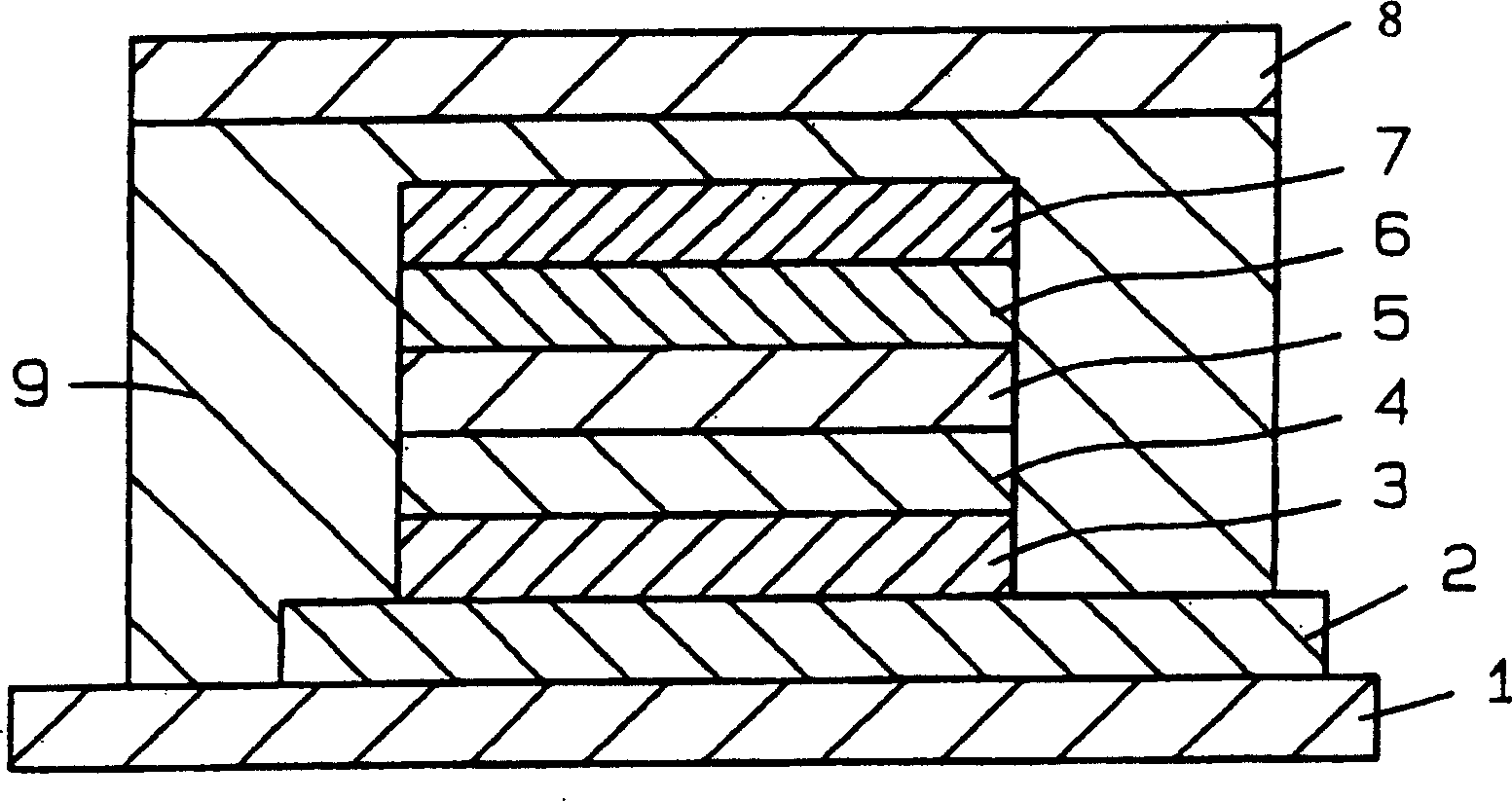

[0140] (2) Fabrication of the organic EL element substrate 2

[0141] Using the same method as in Example 1, after cleaning the glass substrate (25 mm x 25 mm x 0.7 mm), an aluminum electrode film was formed to a thickness of 1000 Å as a transparent supporting substrate. Next, fix the transparent support substrate on the substrate holder of the vacuum evaporation device, put 200 mg of α-NPD into the first bisque crucible, put 200 mg of Alq3 into the second bisque crucible, and heat the Put 200mg of lithium fluoride in the boat, and reduce the pressure in the vacuum chamber to 1×10 -4 Pa. Subsequently, lithium fluoride was formed into a 5 Å thick film at a deposition rate of 0.2 Å / s, and then Alq3 was formed into a 600 Å thick light emitting layer at a deposition rate of 15 Å / s. Next, α-NPD was deposited on the substrate at a deposition rate of 15 Å / s to form a hole transport layer with a film thickness of 600 Å. Then, the tran...

Embodiment 10

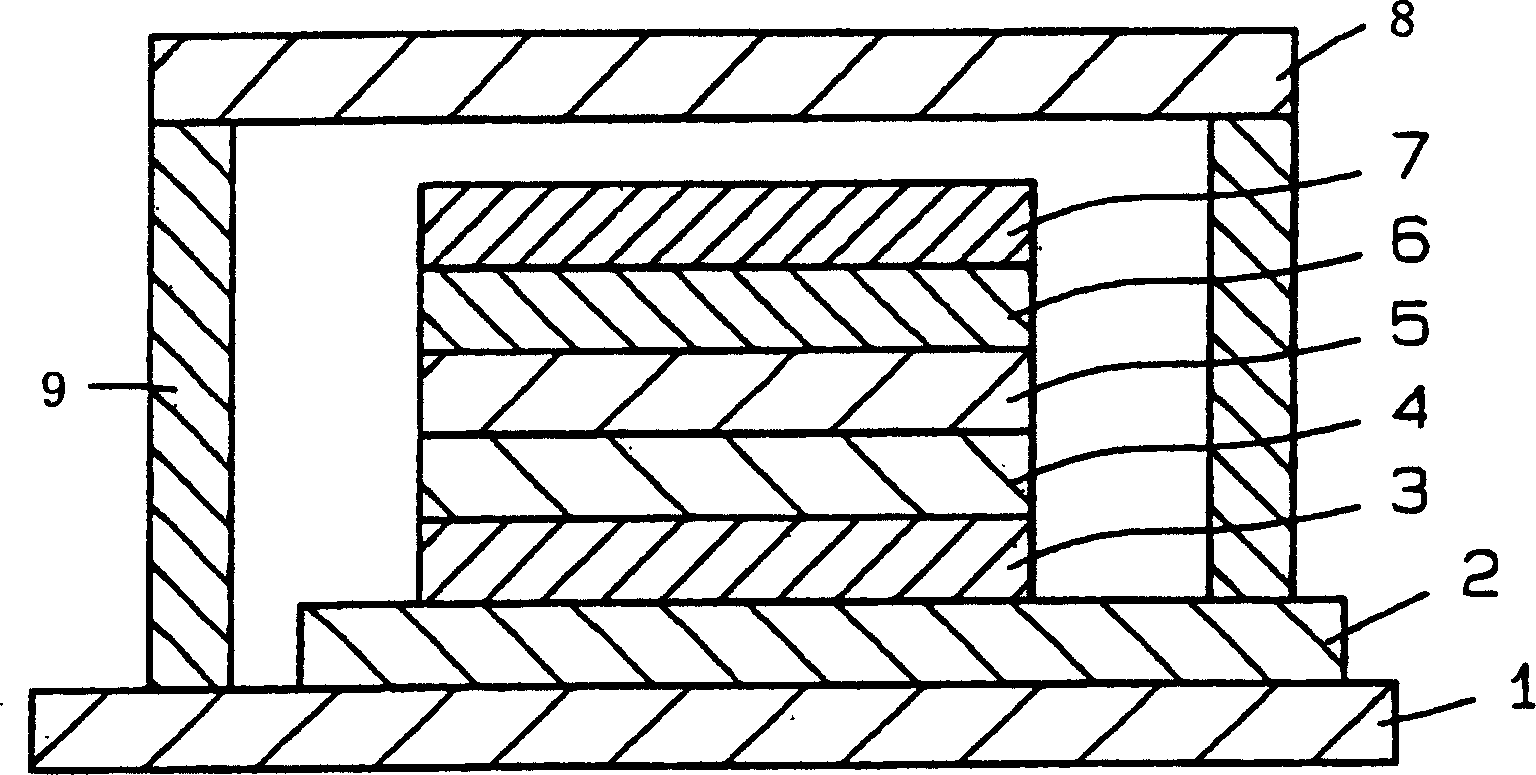

[0154] (1) Production of organic EL elements

[0155] An ITO electrode was formed into a film with a thickness of 100 nm on a glass substrate of 25 mm×25 mm×0.7 mm, and the formed member was used as a transparent supporting substrate. Use acetone to carry out ultrasonic cleaning for 15 minutes, carry out ultrasonic cleaning with alkaline aqueous solution for 15 minutes, then carry out ultrasonic cleaning with isopropanol for 15 minutes, and then use boiling isopropanol to clean for 10 minutes, and then use a UV-ozone cleaner ( "NL-UV253" manufactured by Nippon Laser Electronics Co., Ltd.) was pretreated. Next, this transparent support substrate was fixed on a substrate holder of a commercially available vacuum evaporation device (manufactured by Nippon Vacuum Technology Co., Ltd.), and N,N'-bis(1-naphthyl)-N was placed in a bisque crucible, 200 mg of N'-diphenylbenzidine (α-NPD), and 200 mg of tris(8-hydroxyquinoline) aluminum (Alq3) were placed in other bisque crucibles, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com