Wall body heat insulating construction method

A construction method and wall technology, applied in the direction of thermal insulation, building components, etc., can solve the problems that the structural performance must be tested, the wall structure changes greatly, and the construction period is difficult to guarantee, so as to avoid labor and mechanical use costs and save construction. Time and cost, the effect of saving usage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

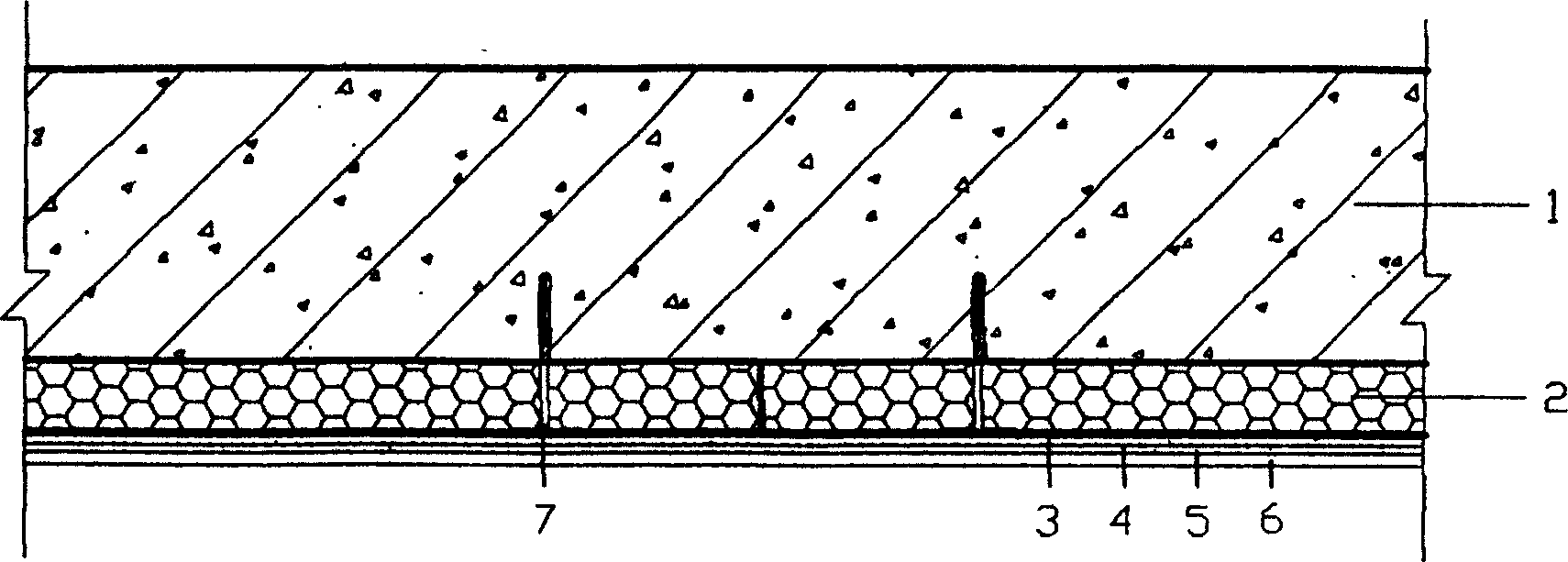

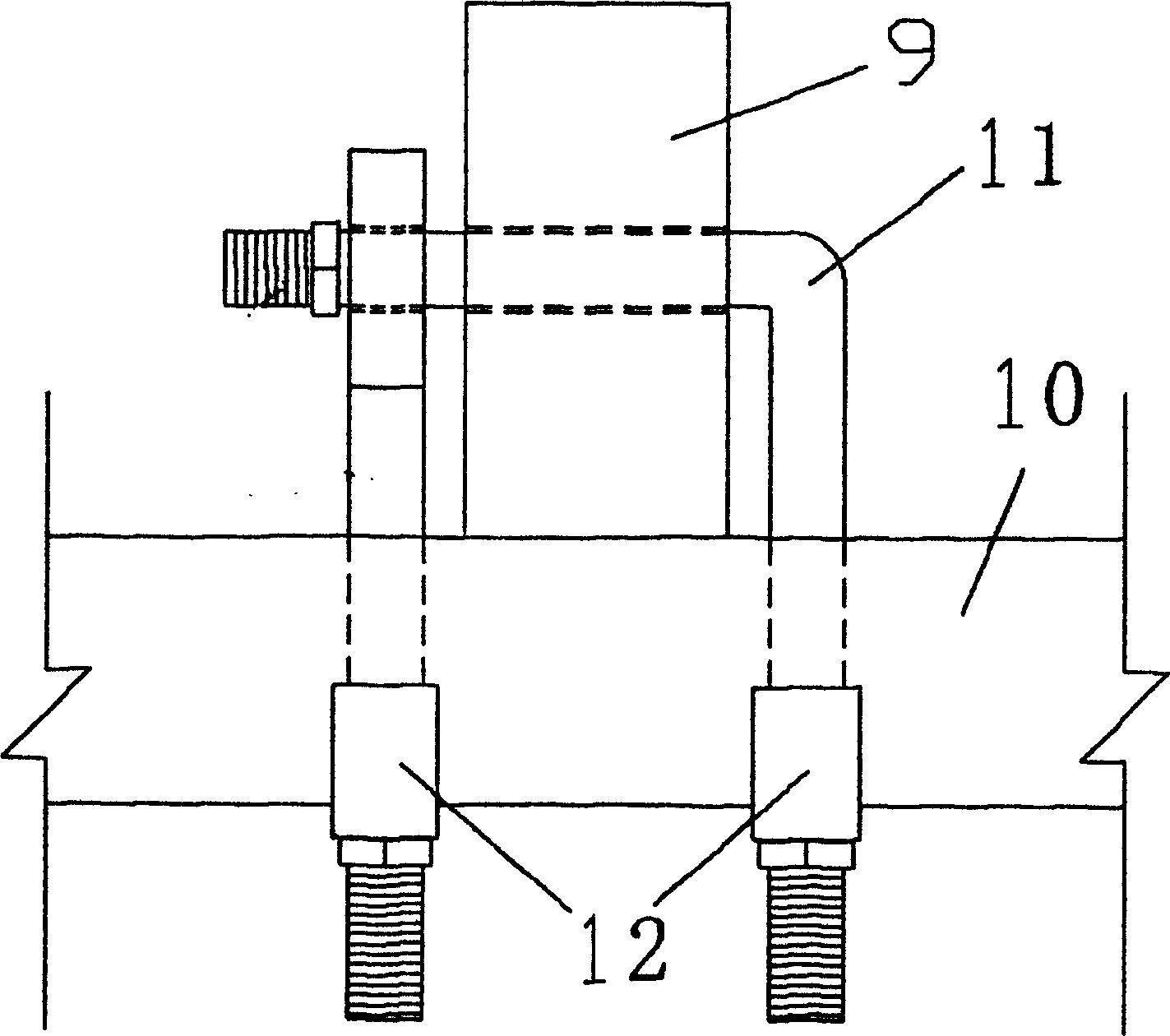

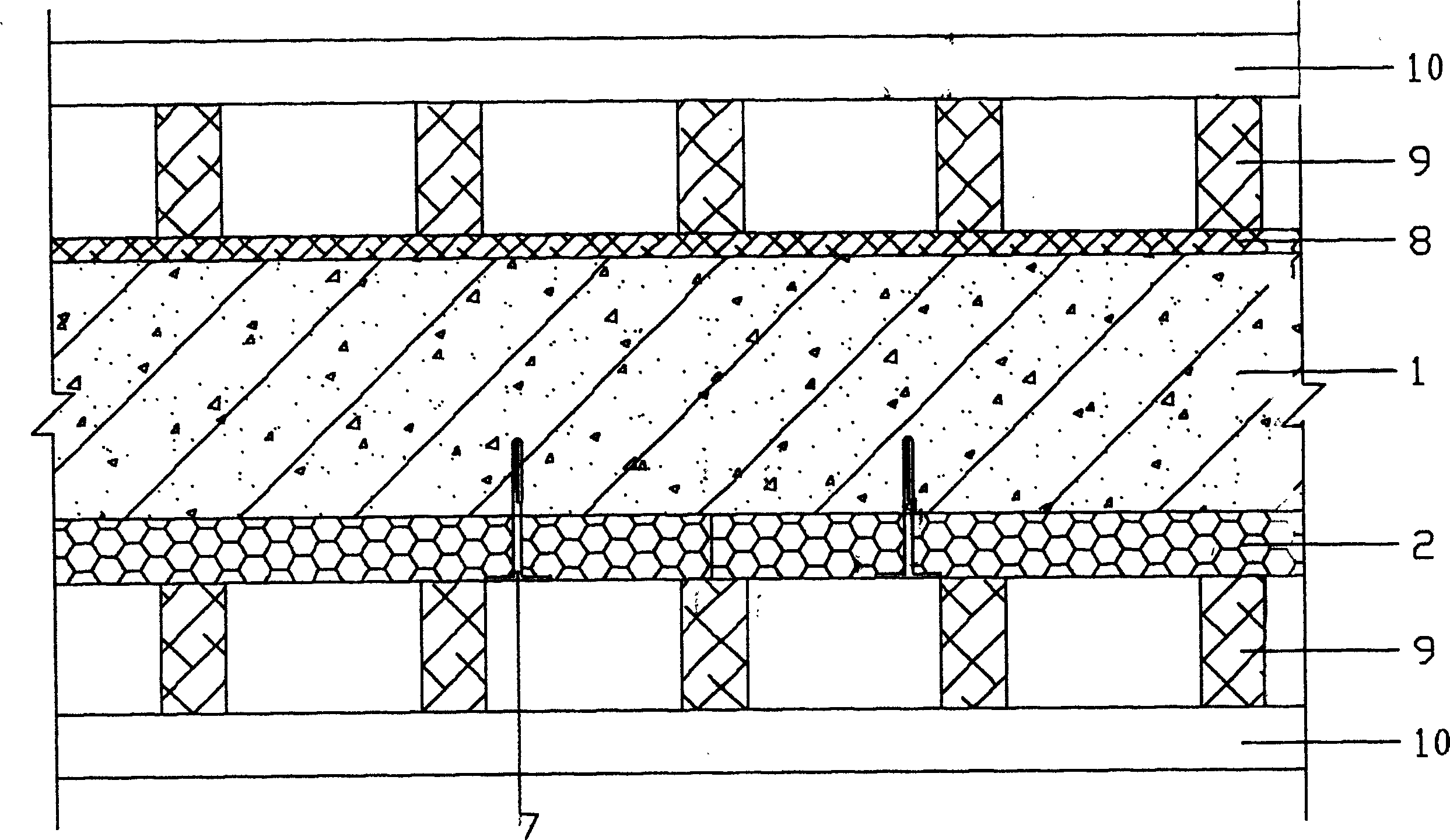

[0011] The present invention comprises the following steps: firstly make the thermal insulation formwork 2 and its support, bind the base wall reinforcement, support the common formwork 8 inside the base wall 1 position, and set its support, and then install the base wall outside the base wall 1 position Set the thermal insulation formwork 2, pre-embed the anchor bolt 7 on the thermal insulation formwork 2, set the wooden square 9 on the outside of the thermal insulation formwork 2, and set the steel pipe 10 on the outside of the wooden cubicle 9, then pour concrete at the position of the base wall 1, and remove the ordinary formwork after the concrete is formed 8. Wooden square 9 and steel pipe 10, repair and surface treatment the thermal insulation formwork 2, use a slotter to cut out grooves on the thermal insulation formwork 2 to make grid seams, then brush the interface agent on the thermal insulation formwork 2, and wait for the interface agent After drying, apply the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com