Production for nanometer nickel powder

A nano-metal and nickel powder technology, which is applied in the field of preparation of nano-metal nickel powder, can solve the problems of reaction heating and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

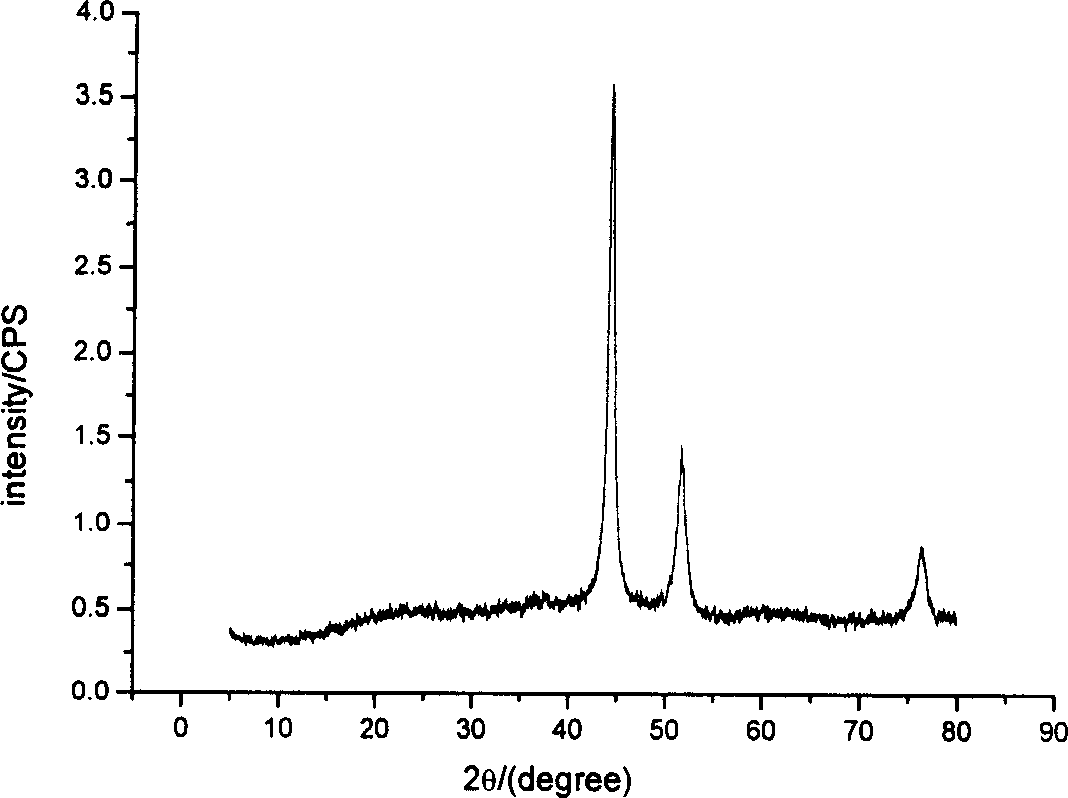

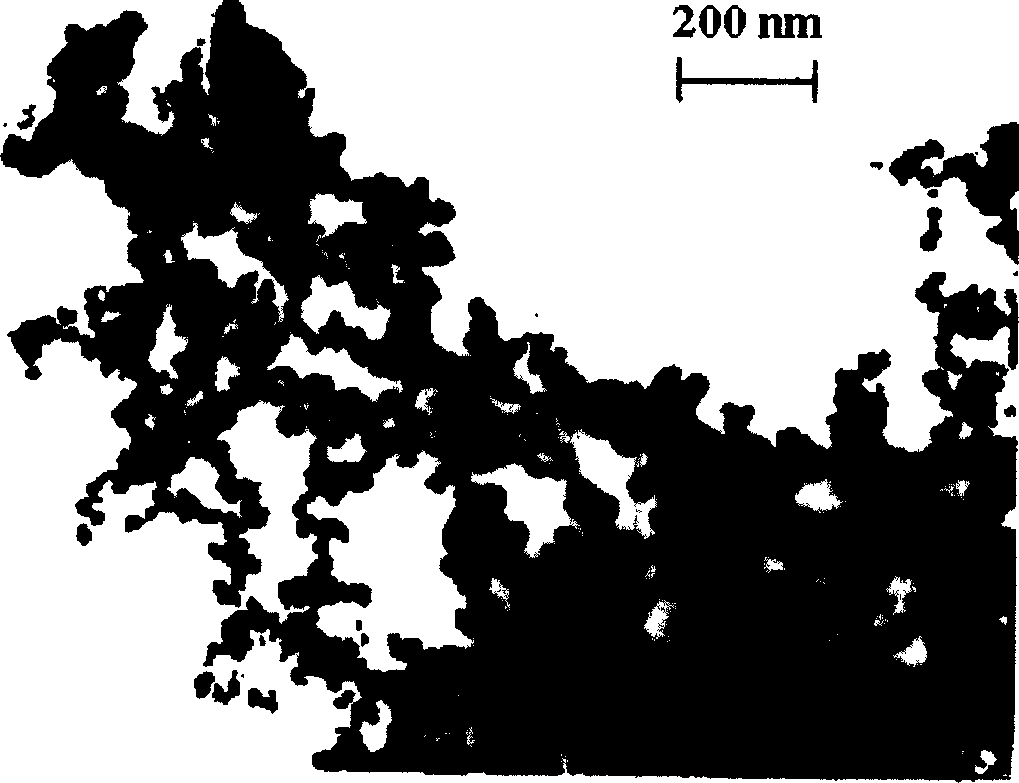

Embodiment 1

[0020] Press W NaOH :W NiCl2·6H2O =2:1; M N2H4·H2O : M NiCl2·6H2O =4.8:1; W NaBH4 :W NiCl2·6H2O =1.6‰:1. 4.2gNiCl 2 ·6H 2 O was dissolved in 15.8ml 95% ethanol aqueous solution to form solution A; 8.4g NaOH was added to 8.5ml hydrazine hydrate solution with a mass percentage of 50%, and stirred to form a paste mixture B; 0.3351g NaBH 4 Be dissolved in 10ml distilled water and be made into solution C (NaBH in following each embodiment 4 The concentration of the solution is the same as in this example). Take 0.2ml NaBH 4 solution, added to solution A to induce the reaction, then quickly add the pasty mixture B to the above solution, stir with a magnetic stirrer, the reaction proceeds quickly, and the black precipitate generated during the reaction is washed with distilled water, and then washed with ethanol After washing, replacing, dehydrating and drying, the nano metal nickel powder is obtained.

[0021] Analysis of residual Ni in the filtrate by atomic absorption s...

Embodiment 2

[0024] Press W NaOH :W NiCl2·6H2O =1.1:1; M N2H4·H2O : M NiCl2·6H2O =1.9:1; W NaBH4 :W NiCl2·6H2O =0.8‰:1. 4.2g NiCl 2 ·6H 2 O was dissolved in 13.6ml of 95% aqueous ethanol to form solution A; 4.5g of NaOH was added to 3.4ml of 50% by mass hydrazine hydrate solution, and stirred to form a pasty mixture B. Take 0.1ml NaBH 4 solution, added to solution A to induce the reaction, then quickly add the pasty mixture B to the above solution, stir with a magnetic stirrer, the reaction proceeds quickly, and the black precipitate formed in the reaction is washed with distilled water, and then washed with ethanol After washing, replacing, dehydrating and drying, the nano metal nickel powder is obtained.

[0025] The BET specific surface area is 129m 2 / g, D is about 6nm.

Embodiment 3

[0027] Press W NaOH :W NiCl2·6H2O =2:1; M N2H4·H2O : M NiCl2·6H2O =4.8:1; W NaBH4 :W NiCl2·6H2O =0.8‰:1. 4.2g NiCl 2 ·6H 2 O was dissolved in 15.8ml of 95% aqueous ethanol to form solution A; 8.4g of NaOH was added to 8.5ml of 50% by mass hydrazine hydrate solution, and stirred to form a pasty mixture B. Take 0.1ml NaBH4 solution, added to solution A to induce the reaction, then quickly add the pasty mixture B to the above solution, stir with a magnetic stirrer, the reaction proceeds quickly, and the black precipitate generated during the reaction is washed with distilled water, and then washed with ethanol After washing, replacing, dehydrating and drying, the nano metal nickel powder is obtained.

[0028] The BET specific surface area is 49m 2 / g, D is about 14nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com