Process for extracting gold, platinum and palladium from goldmine

A technology of gold ore and gold concentrate, which is applied in the field of extracting gold from platinum, palladium, refractory gold ore and gold concentrate, can solve the problems of increased maintenance costs, low product yield, and environmental pollution, and achieve production The effect of cost reduction, equipment investment reduction and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

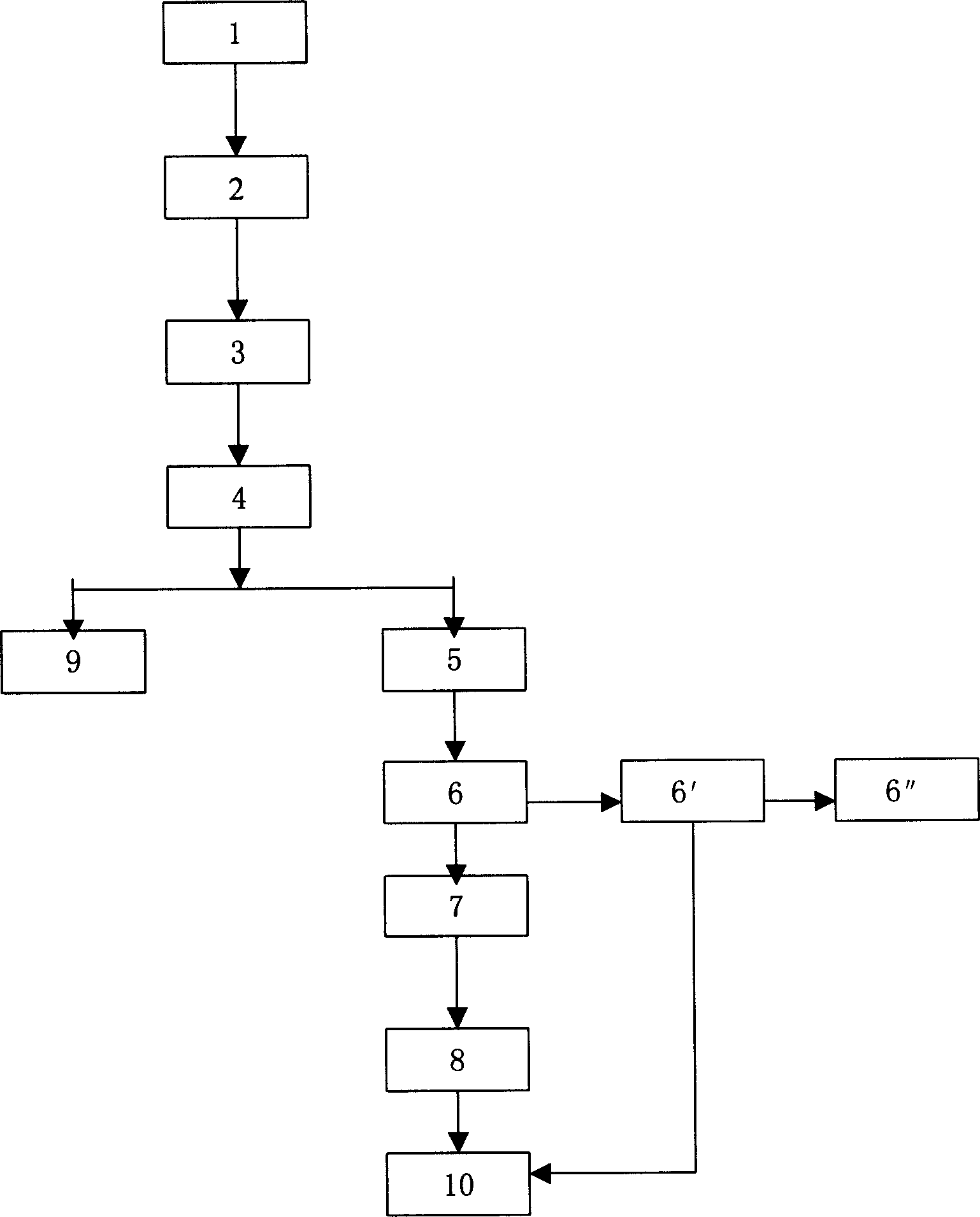

Image

Examples

Embodiment 1

[0041] Example 1: 10,000 grams of Beishan gold mine (which contains 1.2% of C, 25% of S, and 8% of As) is crushed and finely ground to -200 mesh (85% passes), and the resulting gold ore powder is heated to 800°C , feed oxygen for 2.5 hours, decarburization, arsenic fixation, and sulfur fixation. The ore powder obtained after pretreatment is added to the agitator for leaching. The leachate is a 30% (NaCl) solution, and 3% of the oxidizing agent is added to the solution. Among the added oxidizing agents, NaClO 4 、H 2 o 2 , NaClO 3 Each takes one-third. Adjust the solid-liquid ratio to 1:5, stir at a temperature of 70°C, and react for 2.5 hours. After the reaction is completed, the solution is filtered and separated, and the filtrate is separated from gold with resin or activated carbon. The resin or activated carbon that adsorbs gold is desorbed. The desorption solution is electrolyzed as the electrolyte, and gold is precipitated at the anode of the electrolysis, and the gold...

Embodiment 2

[0042]Example 2: 15,000 grams of a certain gold ore (which contains S14%, As 3.5%) is pulverized and finely ground to -200 mesh (85% passes through), and the resulting gold ore powder is heated to 750°C, and oxygen is fed into it. For 3.0 hours, arsenic and sulfur were fixed, and the ore powder obtained through roasting pretreatment was added to the agitator for leaching. The leaching solution was a 28% (NaCl) solution, and 3% of the oxidizing agent was added to the solution. In the added oxidizing agent, NaClO 4 、H 2 o 2 , NaClO 3 Each takes one-third. Adjust the solid-liquid ratio to 1:4, stir at a temperature of 75°C, and pass the reaction time for 2.5 hours. After the reaction is completed, filter and separate, and separate the gold with resin or activated carbon. The resin or activated carbon that adsorbs gold is desorbed and the solution is used as electrolysis solution, electrolysis, gold is precipitated on the anode of electrolysis, and the gold is removed and cast ...

Embodiment 3

[0043] Embodiment 3: 50,000 grams of gold ore (wherein containing C 1.0%, S 15%, As 3.5%) of a certain scene ore is through crushing, finely ground to-200 order (by 85%), and the gold ore powder of gained is heated To 800°C, feed oxygen for 2.5 hours, fix arsenic, decarburize, and fix sulfur. The ore powder obtained after pretreatment is added to the mixer. The leachate is a 25% (NaCl) solution, and 2% of the oxidant is added to the solution. NaClO in oxidizing agent 4 、H 2 o 2 , NaClO 3 Each takes one-third. Adjust the solid-liquid ratio to 1:5, stir at a temperature of 80°C, and pass the reaction time for 2.5 hours. After the reaction is completed, filter and separate, and use resin or activated carbon to adsorb gold. The gold-adsorbed resin or activated carbon is desorbed and desorbed. As electrolyte electrolysis, gold is precipitated on the anode of electrolysis, the gold is removed, and cast into gold ingots, the yield of gold is 97%; the remaining mother liquor after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com