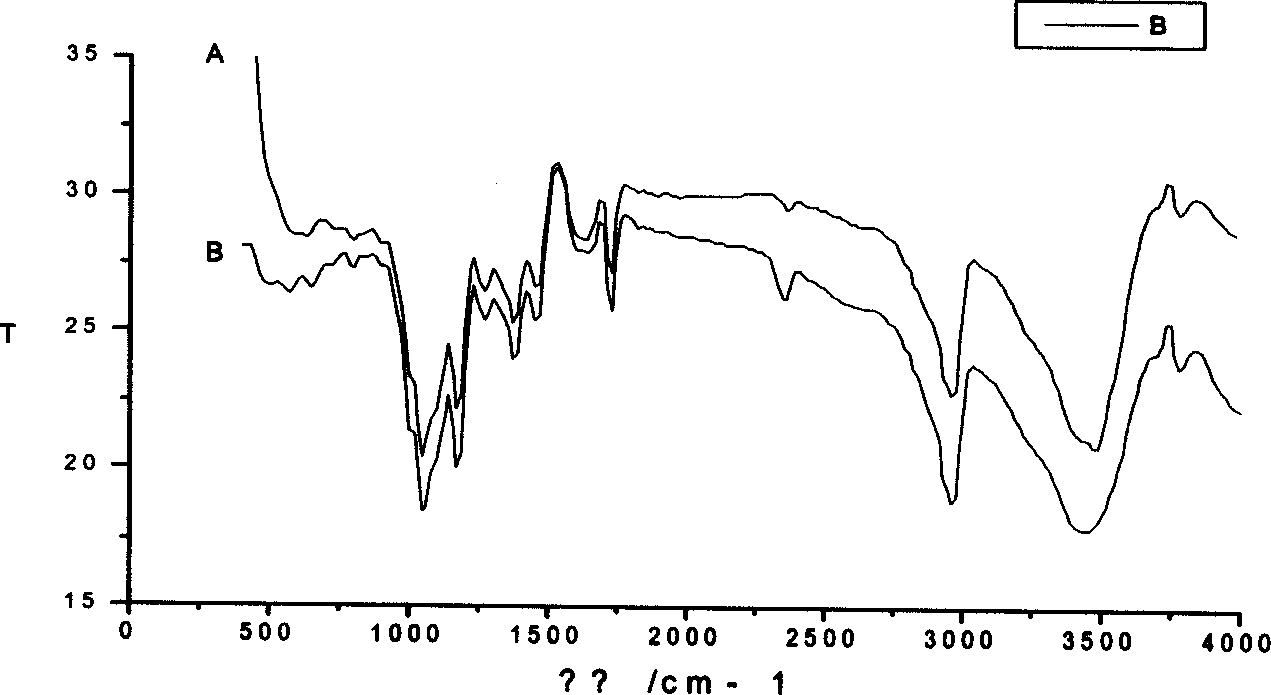

Method for preparing azithromycin superfine powder by ultrasound homogenization dissolvent diffusion method

A technology of azithromycin and phacoemulsification, which is applied in powder delivery, pharmaceutical formulations, medical preparations containing active ingredients, etc. It can solve the problems of unstable absorption and low bioavailability of azithromycin, and achieve the effect of inhibiting crystal growth and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: be the preferred example of the present invention.

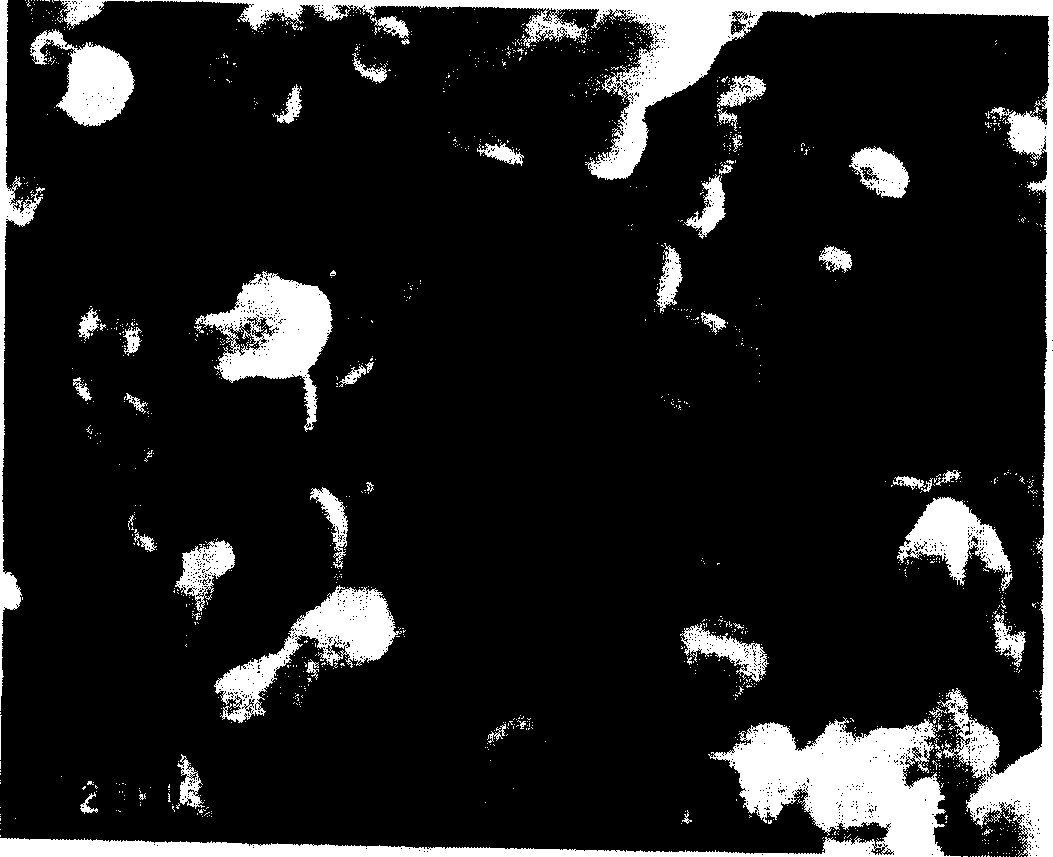

[0025] Raw material of azithromycin, average particle size 20μm (Shanghai Modern Pudong Pharmaceutical Co., Ltd.), SEM photo see figure 2 ; Polyethylene glycol, A.R grade (Tianjin Damao Chemical Instrument Supply Station); absolute ethanol, A.R grade (Tianjin Benchmark Chemical Reagent Co., Ltd.):

[0026] Other reagents were of analytical grade, and the experimental water was distilled water.

[0027] Add 100ml of polyethylene glycol stabilizer aqueous solution with a concentration of (1%, w / v) into a 250ml Erlenmeyer flask, place it in an ice-water bath at 5°C, and under ultrasonic conditions (50K-Hz), add 1ml Slowly add 25ml of azithromycin ethanol solution (the concentration of azithromycin is 0.03mol / L) dropwise at a speed of 1 / min until the solution system becomes turbid. After standing still for 2 hours, centrifuge at high speed until the separation is complete to obtain a solid sample. Then t...

Embodiment 2

[0029] The operating parameters are the same as those in Example 1, except that the diffusion crystallization temperature is at room temperature of 25° C., and the samples obtained by SEM detection show serious agglomeration and agglomeration. And because the crystallization speed is accelerated, the particle size of the sample tends to increase, and at least 90% of the particles have a particle size above 1.0um.

[0030] Effect of temperature on particle size and morphology (comparison of embodiment 1 and embodiment 2):

[0031] The main factors affecting the crystal size are the nucleation rate and the crystallization rate of the crystal, and the crystallization rate is greatly affected by the temperature. When the temperature rises, because the crystallization speed of the product is accelerated, the phenomenon of product agglomeration and agglomeration is more serious. However, in an ice-water bath at 0-5°C, the nucleation rate of the product is much faster than the cryst...

Embodiment 3

[0033] Operating parameter is identical with embodiment 1, and only difference is that the concentration of azithromycin ethanol solution is 0.1mol / L, detects by SEM, as Figure 4 As shown, the chances of the particles colliding with each other increase due to the increase of the concentration, so that the particles become larger and agglomerate. At least 80% of the particles have a particle size above 1.0um.

[0034] The impact of azithromycin concentration on particle size and morphology (comparison of embodiment 1 and embodiment 3):

[0035] The concentration of azithromycin in the solution system has a great influence on the formation and morphology of particles.

[0036] Characterized by scanning electron microscopy, the results are shown in image 3 , Figure 4 , it can be seen from the figure that at a lower concentration (≤0.03mol / L), the obtained particles are mainly spherical, with a uniform particle size. As the concentration increases, the chance of particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com