Connection method for tube plate and pipe joint of tube-shell/tube-sheet type heat exchanger

A technology for heat exchangers and pipe joints, used in heat exchange equipment, welding media, welding equipment, etc., can solve the problems of high manufacturing cost, low production efficiency, and high repair rate, and achieve low manufacturing cost, high compactness, and high quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

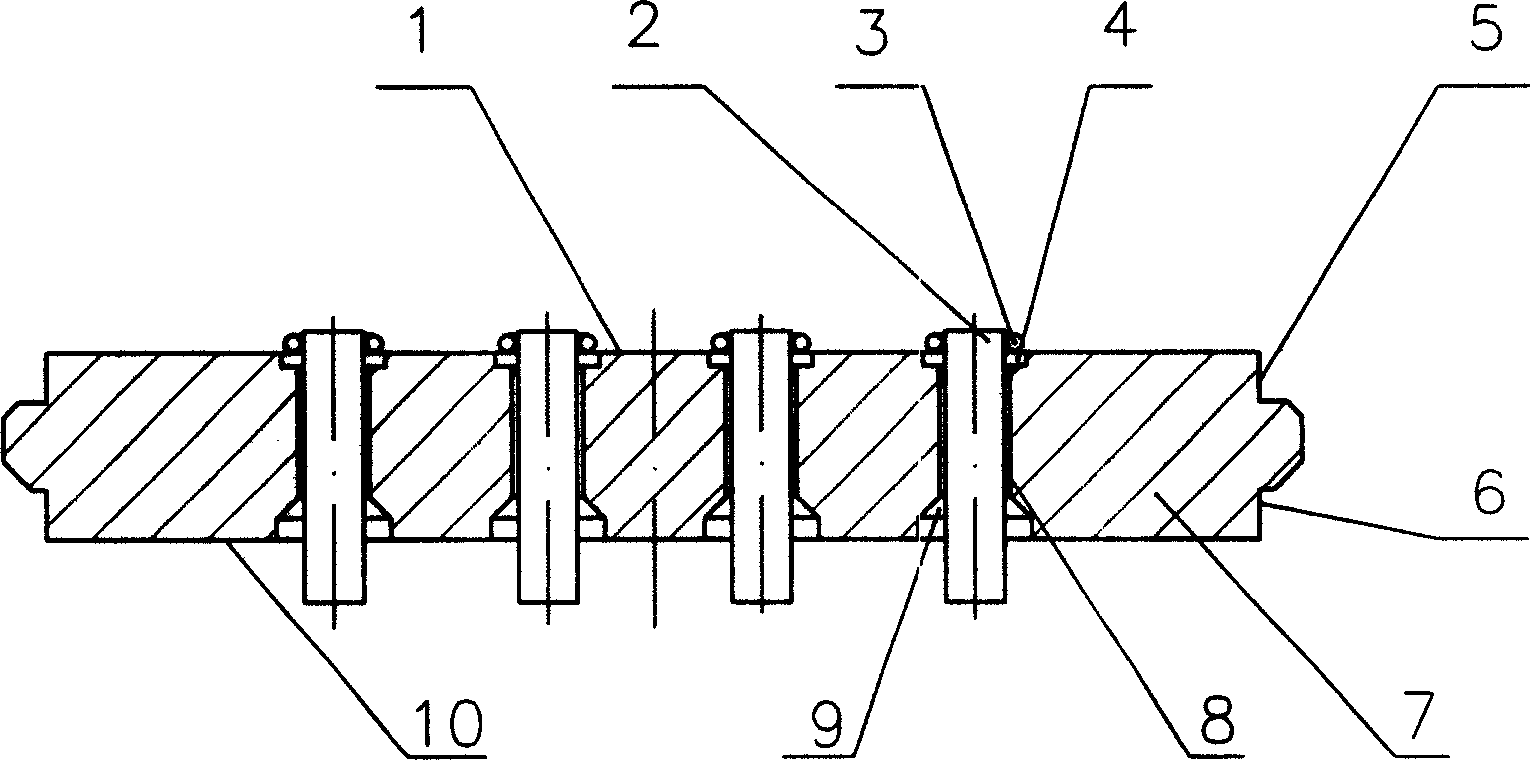

[0013] refer to figure 1 , GK91X397-00-00 type shell-and-tube heat exchanger, the tube sheet 7 is made of low carbon steel, and a set of longitudinal through holes 8 are opened on it, and the bottom of the through holes 8 corresponds to 10 places on the inner surface of the tube sheet A guide counterbore 9 is opened, and the top of the through hole 8 corresponds to the outer surface 1 of the tube sheet, and a welding ring preset counterbore 4 is opened, and the pipe joint part 2 of the heat dissipation pipe penetrates into the through hole 8 for positioning, and then Follow these steps:

[0014] 1) Preset BAg40CuZnSnNi silver-based solder ring 3 in the preset sink hole at the opening of the tube plate, the wire diameter of the solder ring 3 is 1mm, the inner diameter of the solder ring is 5.4mm, and the axial dimension of the solder ring is 1mm ;

[0015] 2) Spray an appropriate amount of brazing flux saturated aqueous solution (QJ102) on the pipe joint; the brazing flux typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com