Steam blow off equipment of pressure cooker

A technology of discharge device and pressure cooker, applied in the field of pressure cooker, can solve problems such as poor steam discharge, inability to maintain pressure in the pot, channel scaling, etc., and achieve the effects of reducing the area of foreign matter scaling, preventing poor valve action, and preventing eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

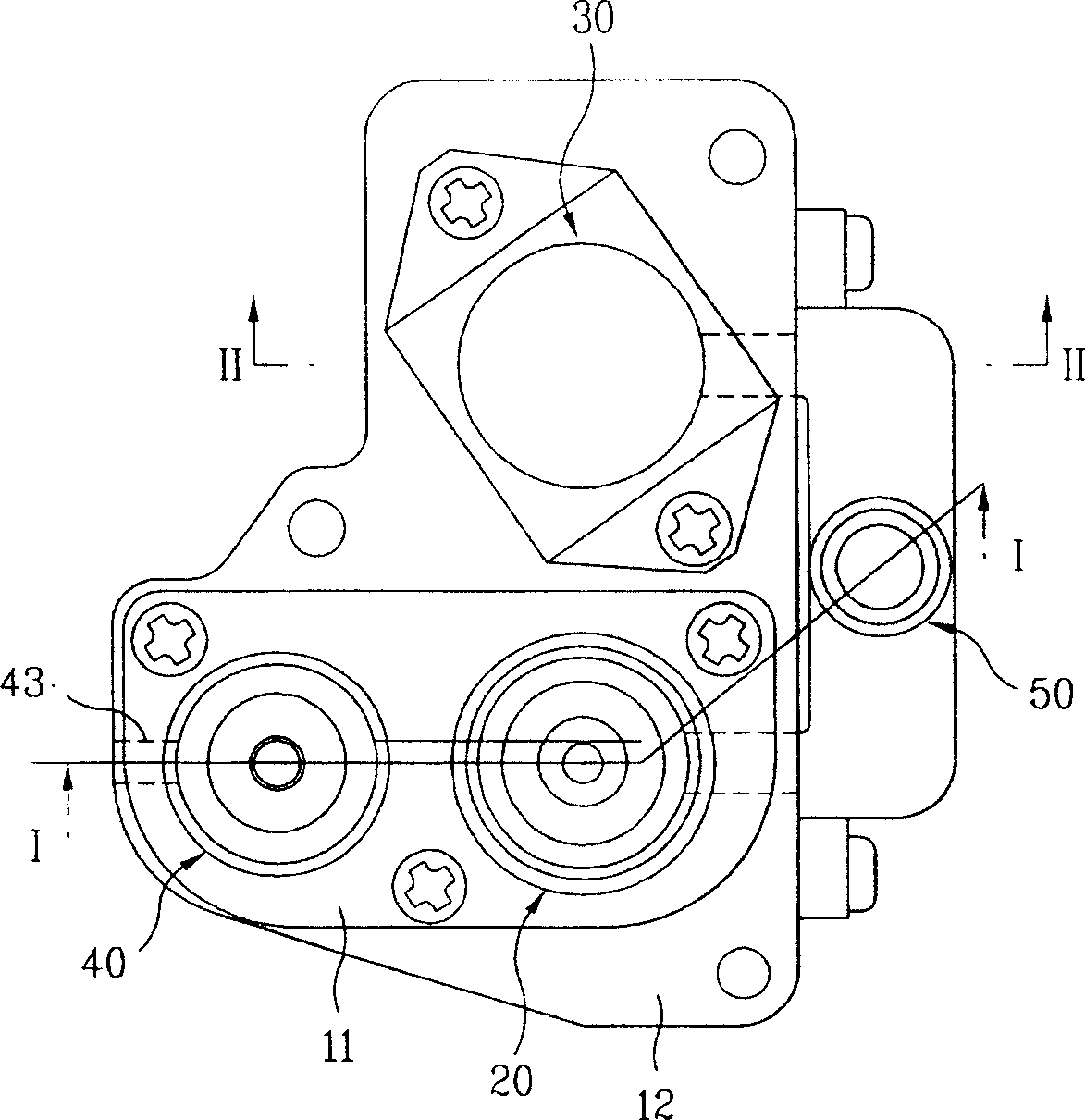

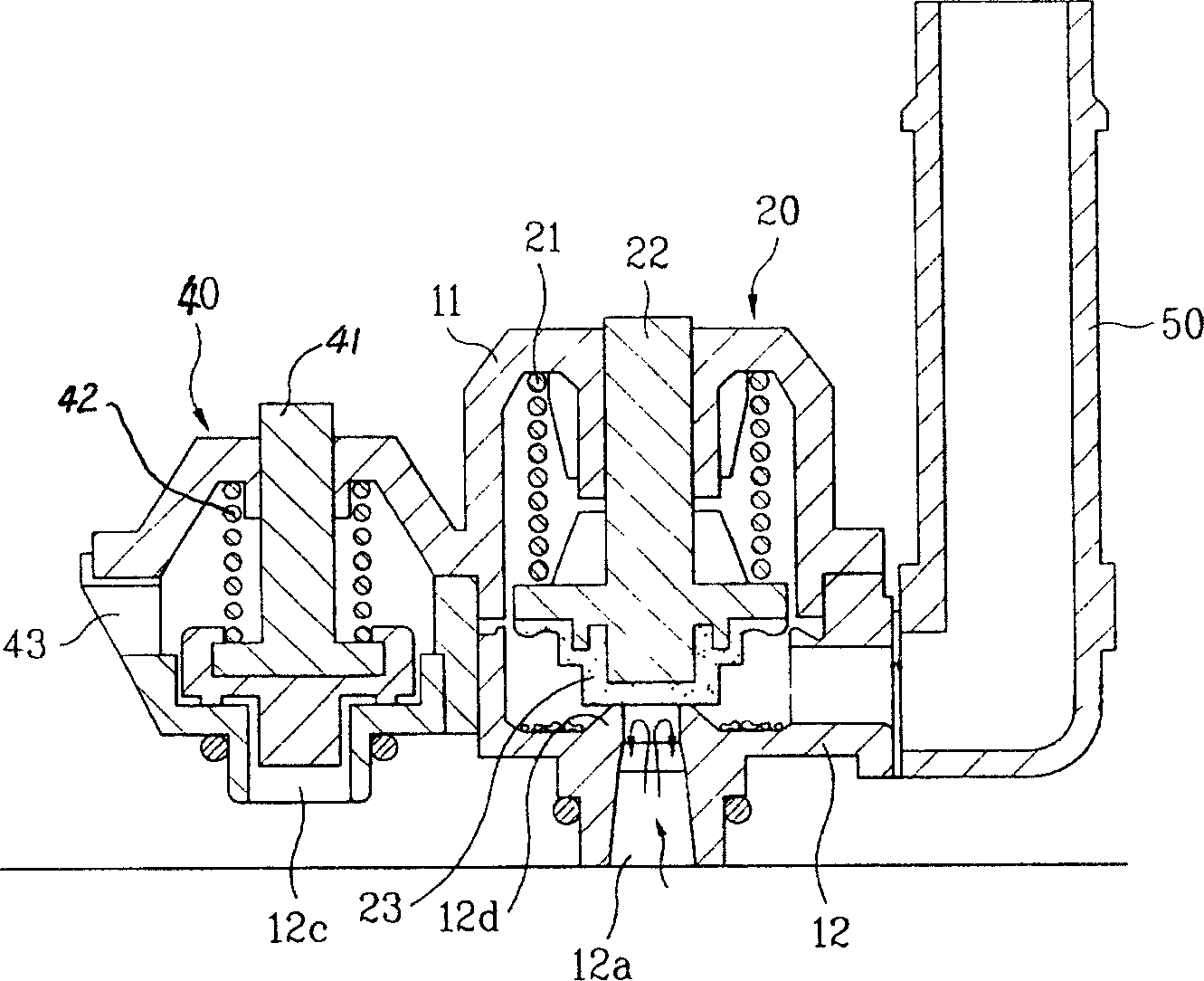

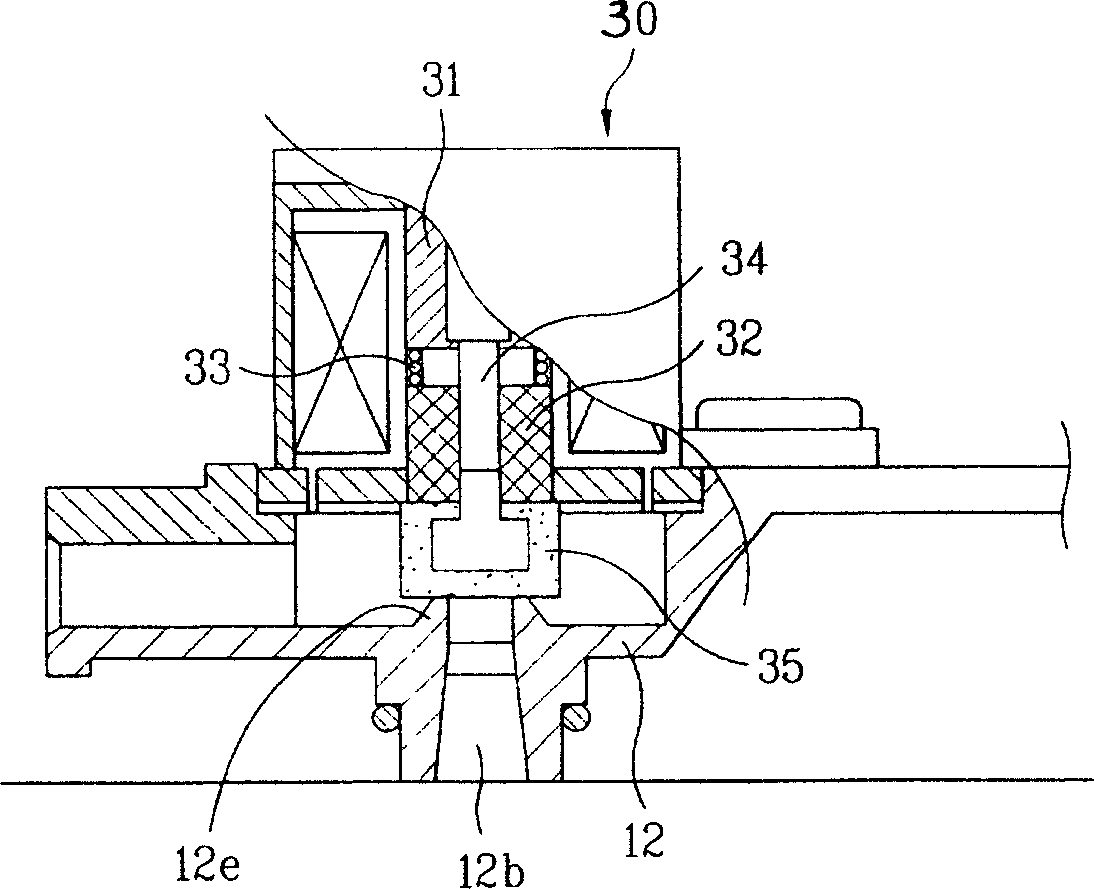

[0036] The invention provides a steam discharge device for a pressure cooker, comprising: a lower mounting plate 120 fixed on the electric heating plate inside the cover of the pressure cooker and having at least one steam discharge hole; fixed between the upper end of the lower mounting plate and the lower mounting plate An upper mounting plate 110 forming any valve space; an elastic element 130 installed on the valve space; a flange 140 that presses down under the action of the elastic element, and the lower end of the flange 140 has a downward and inwardly inclined A membrane 150 of a closed structure that closes the steam discharge hole 121 .

[0037] The part where the steam discharge hole 121 is formed on the lower mounting plate 120 is a plane. The lower mounting plate 120 is provided with an upper sharp corner of the steam discharge hole 121 to form a gradually downward inclined surface.

[0038] The diaphragm 150 is shown as a whole forming a conical structure.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com