Novel bladeless oil smoke exhausting device

An exhaust device and oil fume technology, which is applied to the removal of oil fume, household heating, lighting and heating equipment, etc., can solve the problems of dust and oil deposits on the impeller, and it is difficult to clean, so as to reduce the fouling area, simple structure and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

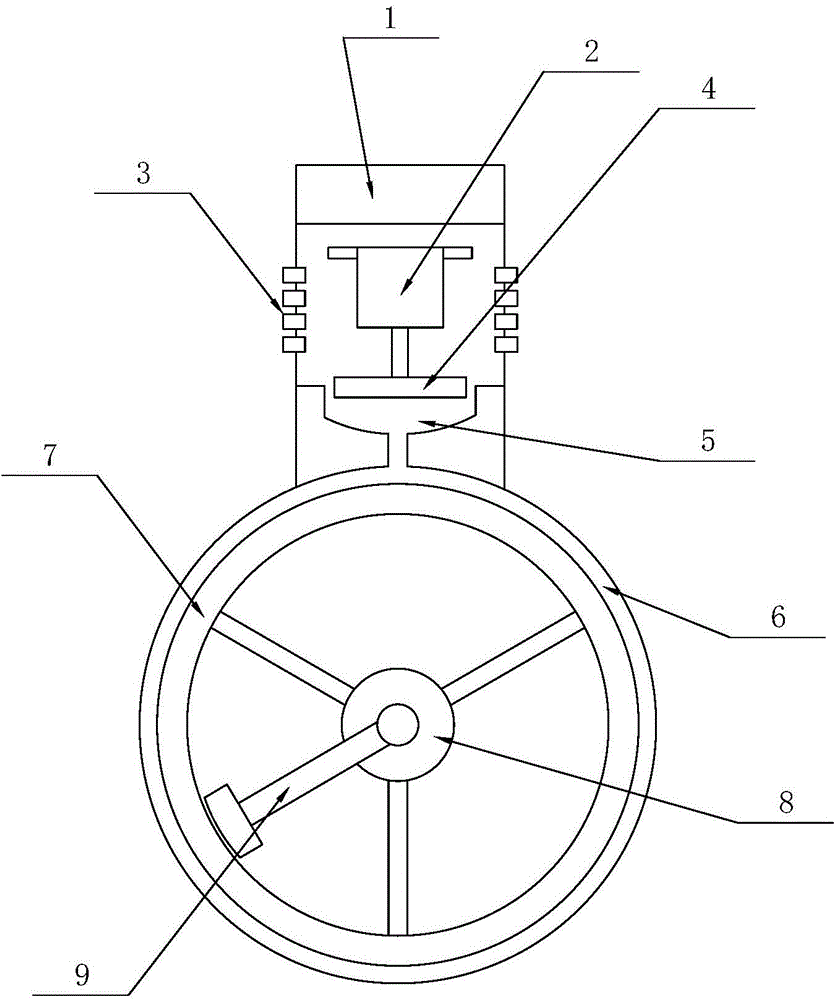

[0011] see figure 1 , this specific embodiment adopts the following technical solutions: it includes oil fume exhaust device 1, first drive motor 2, air intake hole 3, rotating fan blade 4, funnel air pipe inlet nozzle 5, annular guide air path 6, circular Smoke exhaust bracket 7, second drive motor 8, rotary oil suction scraper 9, the inside of the oil fume exhaust device 1 is provided with a first drive motor 2, and several air intake holes 3 are provided on both sides of the first drive motor 2 , the lower end of the first drive motor 2 is provided with a rotating fan blade 4, the lower end of the rotating fan blade 4 is provided with a funnel air pipe inlet nozzle 5, and the lower end of the oil fume exhaust device 1 is provided with an annular guide air passage 6, and the funnel air pipe intake The mouth 5 is connected with the annular flow guide air path 6, and the inside of the ring flow guide air path 6 is provided with a circular smoke exhaust support 7, and the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com