Coaction type food biochemical treating equipment

A common action, biochemical treatment technology, applied in sanitary equipment for toilets, food preservation, application, etc., can solve the problems of inconvenient separation and extraction of materials, troublesome installation, maintenance and cleaning, inability to guarantee discharge effect, etc., to achieve compact structure. , good effect, small temperature rise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

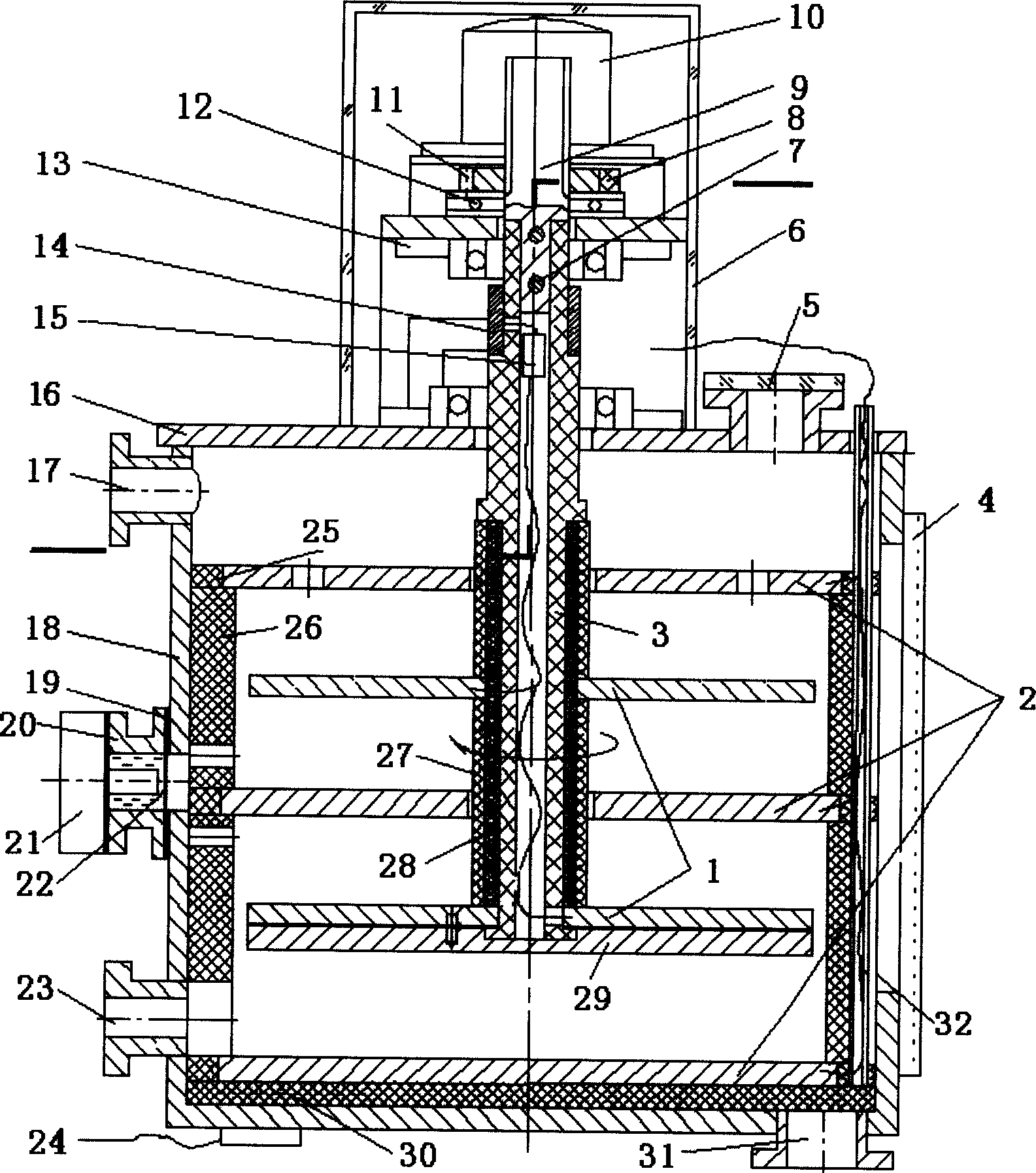

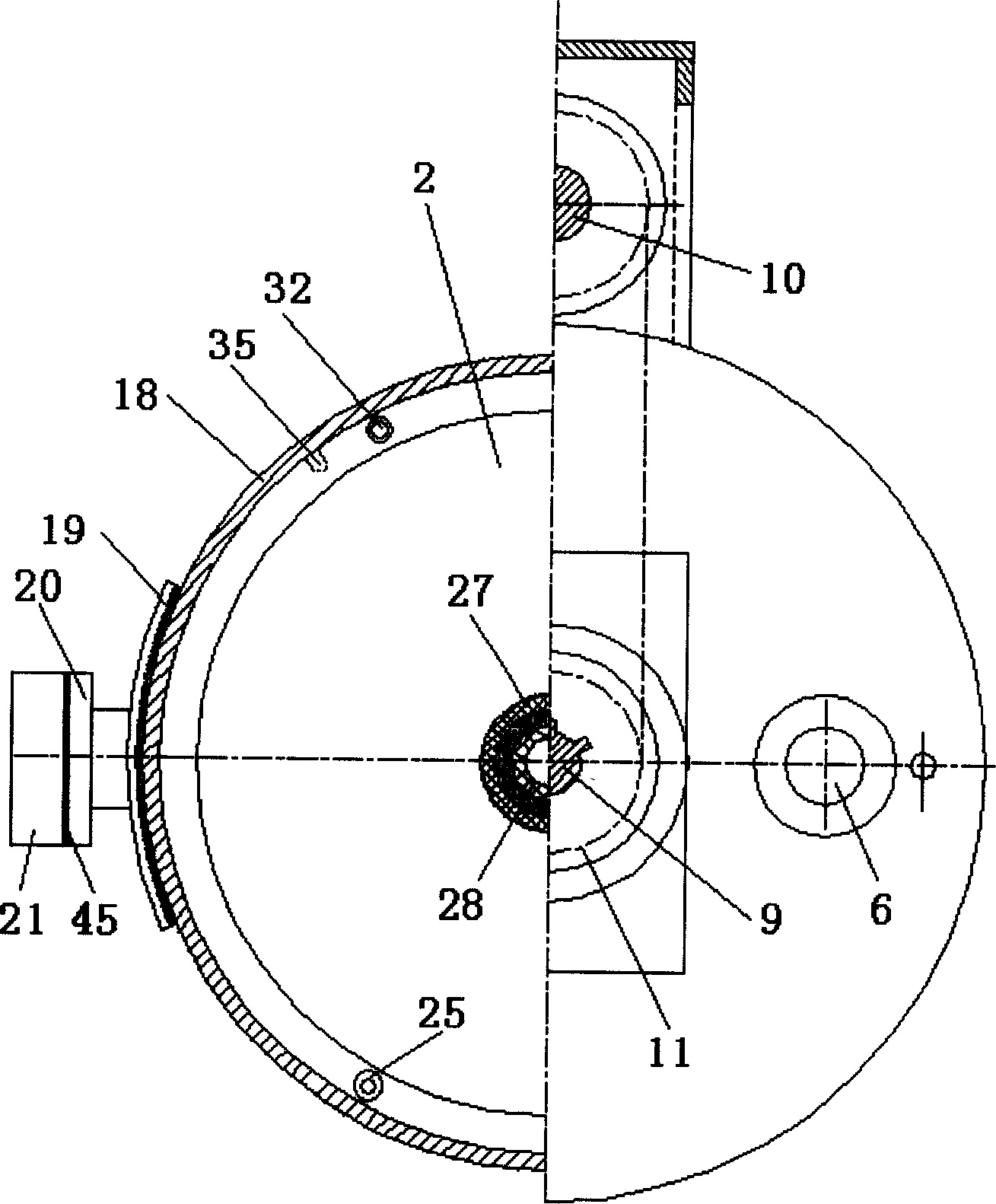

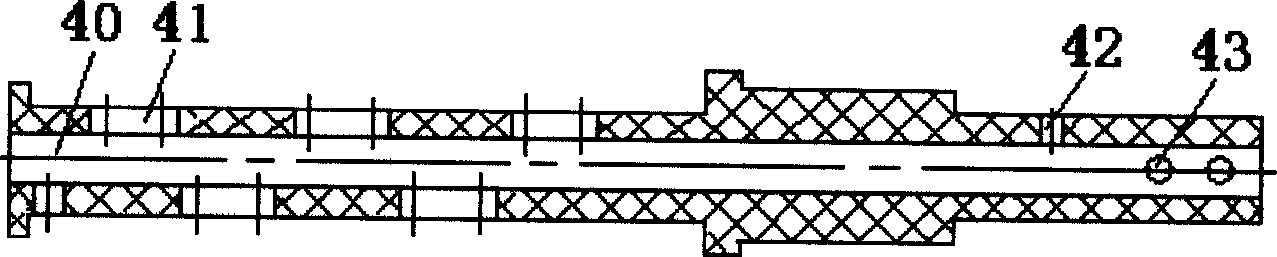

[0024] The present invention mainly consists of 1. moving (positive) electrode, 2. fixed (negative) electrode, 3. hollow nylon shaft, 4. liquid level gauge, 5. observation hole, 6. glass cover, 7. pin, 8. tooth shape Belt, 9. Spline shaft, 10. Stepper motor, 11. Toothed belt pulley, 12. Thrust bearing, 13. Bearing with seat, 14. Wide brush positive pole, 15. Lead frame, 16. Tank cover , 17. Import, 18. Tank body, 19. Gasket, 20. Housing, 21. Ultrasonic generator, 22. Elastic membrane, 23. Outlet, 24. Ground electrode, 25. Small silicone rubber sealing sleeve, 6. Large spacer, 27. Small spacer, 28. Large silicone rubber sealing sleeve, 29. Bottom plate of moving electrode, 30. Pad, 31. Bottom liquid discharge port, 32. Conduit, 33. Nylon pin, 34. Assembly Tool, 35. Tank body guide strip, 36. Plug welding spot, 37. Double tapered hole, 38. Conductive li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com