Process for preparing caprolactam by cyclohexanone-oxime gas phase rearrangement

A technology of cyclohexanone oxime and caprolactam, which is applied in the field of producing caprolactam, can solve problems such as difficult separation, low caprolactam selectivity, and lower quality of caprolactam products, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example illustrates the implementation effect of the method provided by the present invention.

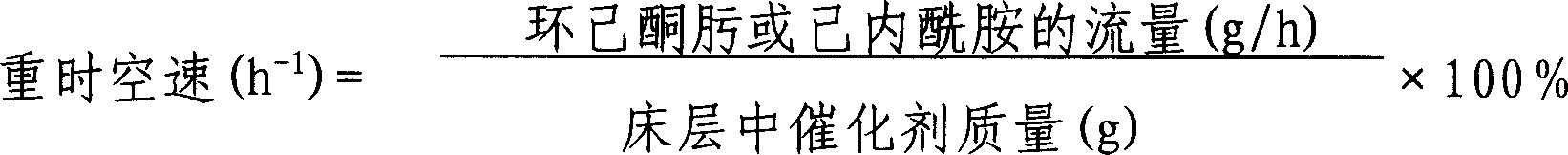

[0034] 4.5 grams of catalyst were charged in the first fixed bed reactor for the gas phase Beckmann rearrangement reaction. Reaction raw material is the ethanol solution of the cyclohexanone oxime of concentration 28% by weight, with advection pump (model is PB-1, Beijing satellite instrument factory produces) with the flow feeding of the ethanol solution of cyclohexanone oxime of 64.3 grams / hour, When the weight space velocity of cyclohexanone oxime is 4 -1 , carrier gas N 2 The flow rate is 7.2L / h, and the catalyst bed reaction temperature is 380°C.

[0035] Water is passed into the gaseous product of above-mentioned rearrangement reaction with the flow rate of 3 grams / hour with advection pump, and mixed material enters the second fixed-bed reactor of internal dress 2.2 grams of catalyzers, rearranges the weight hourly space velocity of the alcoholic solution of pro...

Embodiment 2

[0038] This example illustrates the implementation effect of the method provided by the present invention.

[0039] 4.5 grams of catalyst were charged in the first fixed bed reactor for the gas phase Beckmann rearrangement reaction. Reaction raw material is the ethanol solution of the cyclohexanone oxime of concentration 28% by weight, with the flow feeding of the ethanol solution of cyclohexanone oxime with 32 grams / hour, the weight space velocity of cyclohexanone oxime is 2 hours with advection pump -1 , carrier gas N 2 The flow rate is 3.6L / h, and the catalyst bed reaction temperature is 380°C.

[0040] Water is passed into the gaseous product of above-mentioned rearrangement reaction with the flow rate of 1.5 grams / hour with advection pump, and mixed material enters the second fixed-bed reactor of inner dress 2.2 grams of catalyzers, rearranges the weight hourly space velocity of the alcoholic solution of product caprolactam at 4 o'clock -1 , the reaction temperature is...

Embodiment 3

[0043] This example illustrates the implementation effect of the method provided by the present invention.

[0044] 4.5 grams of catalyst were charged in the first fixed bed reactor for the gas phase Beckmann rearrangement reaction. Reaction raw material is the ethanol solution of the cyclohexanone oxime of concentration 28% by weight, with the flow feeding of the ethanol solution of cyclohexanone oxime with 32 grams / hour, the weight space velocity of cyclohexanone oxime is 2 hours with advection pump -1 , carrier gas N 2 The flow rate is 3.6L / h, and the catalyst bed reaction temperature is 380°C.

[0045] Water is passed into the gaseous product of above-mentioned rearrangement reaction with the flow rate of 6 grams / hour with advection pump, and mixed material enters the second fixed-bed reactor of internal dress 2.2 grams of catalyzers, rearranges the weight hourly space velocity of the alcoholic solution of product caprolactam at 4 o'clock -1 , the reaction temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com