Full automatic opening method and device for paper box

A fully automatic carton technology, applied in the field of automatic cutting, recycling carton strapping and opening the carton lid, can solve the problems of large space occupation, low work efficiency, high labor intensity, etc., to facilitate storage and transportation, and improve work efficiency , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

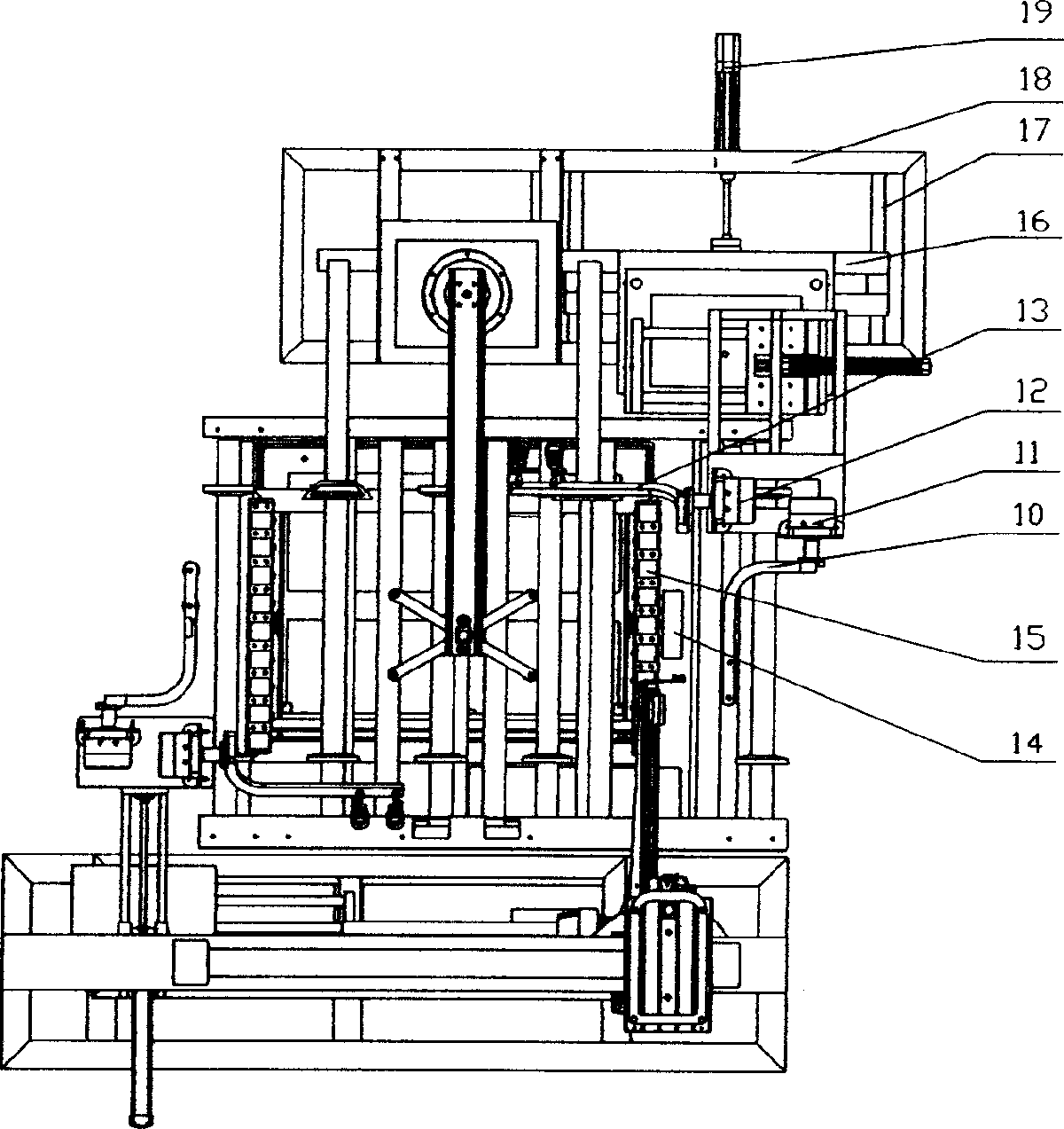

[0022] The unpacking method proposed by the present invention is mainly realized by the following steps: carton conveying and positioning, packing belt removal and recovery, carton flipping, and liner removal. Firstly, a roller conveyor transports the carton to the unpacking station, and the positioning block at the front end of the conveyor realizes the positioning of the front of the carton. There is a jacking mechanism under the roller conveyor, which lifts the upper surface of the carton to a predetermined height and then stops the jacking to realize the positioning of the carton in the height direction. Then, the reciprocating removal and recovery device above the carton can detect, remove, roll up, cut and recover the strapping. Repeat the above process until all straps are recovered. After all the straps are recovered, the box pusher positioning mechanism on the side of the roller conveyor pushes the cartons on the conveyor to the other side to realize the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com