Bacterium-resisting/deodorizing/finishing technology for towel shell fabric

A fabric and process technology, applied in the field of antibacterial and deodorizing finishing technology for towel fabrics, can solve the problems of being easily affected by washing, not durable, and low cleaning ability, and achieve the effects of reasonable process arrangement, shortened process flow, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

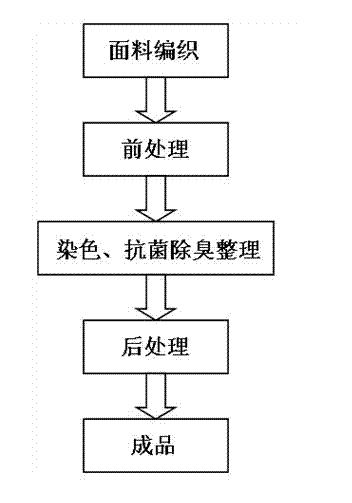

Image

Examples

Embodiment 1

[0019] The specific implementation steps are as follows:

[0020] a) fabric weaving, the towel fabric involved in the present invention selects 172dtex×76f polyester-nylon composite superfine fiber, and uses knitting technology for weaving. The polyester-nylon composite ratio is: 82% polyester and 18% nylon. The towel fabric has a soft luster. Soft and fine texture, good moisture absorption and quick drying performance, strong detergency, easy to wash, and good wear resistance.

[0021] b) Pre-treatment, the pre-treatment process includes alkali weight reduction treatment and oil removal treatment, among which 13g / L 96% sodium hydroxide, 1.0g / L penetrant, and a bath ratio of 1:12 are selected for alkali weight reduction treatment; The oil removal treatment uses 1.8g / L oil removal refining agent, the oil removal temperature is 96°C, and the oil removal time is 20 minutes; the pretreatment process is as follows: 1) Fill the pot with water first, wash with overflow water for 12 m...

Embodiment 2

[0025] The specific implementation steps are as follows:

[0026] a) fabric weaving, the towel fabric involved in the present invention selects 172dtex×76f polyester-nylon composite superfine fiber, and uses knitting technology for weaving. The polyester-nylon composite ratio is: 84% polyester and 16% nylon. The towel fabric has a soft luster. Soft and fine texture, good moisture absorption and quick drying performance, strong detergency, easy to wash, and good wear resistance.

[0027] b) Pre-treatment, the pre-treatment process includes alkali weight reduction treatment and oil removal treatment, among which 14g / L 96% sodium hydroxide, 1.2g / L penetrant are selected for alkali weight reduction treatment, and the bath ratio is 1:15; The deoiling treatment uses 2.0g / L deoiling refining agent, the deoiling temperature is 98°C, and the deoiling time is 18 minutes; the pretreatment process is as follows: 1) Fill the pot with water first, wash with overflow water for 10 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com