Natural wood / synthetic high polymer modification

A high polymer and wood technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of neglecting wood pretreatment for impregnation, neglecting wood drying and curing, and difficult industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

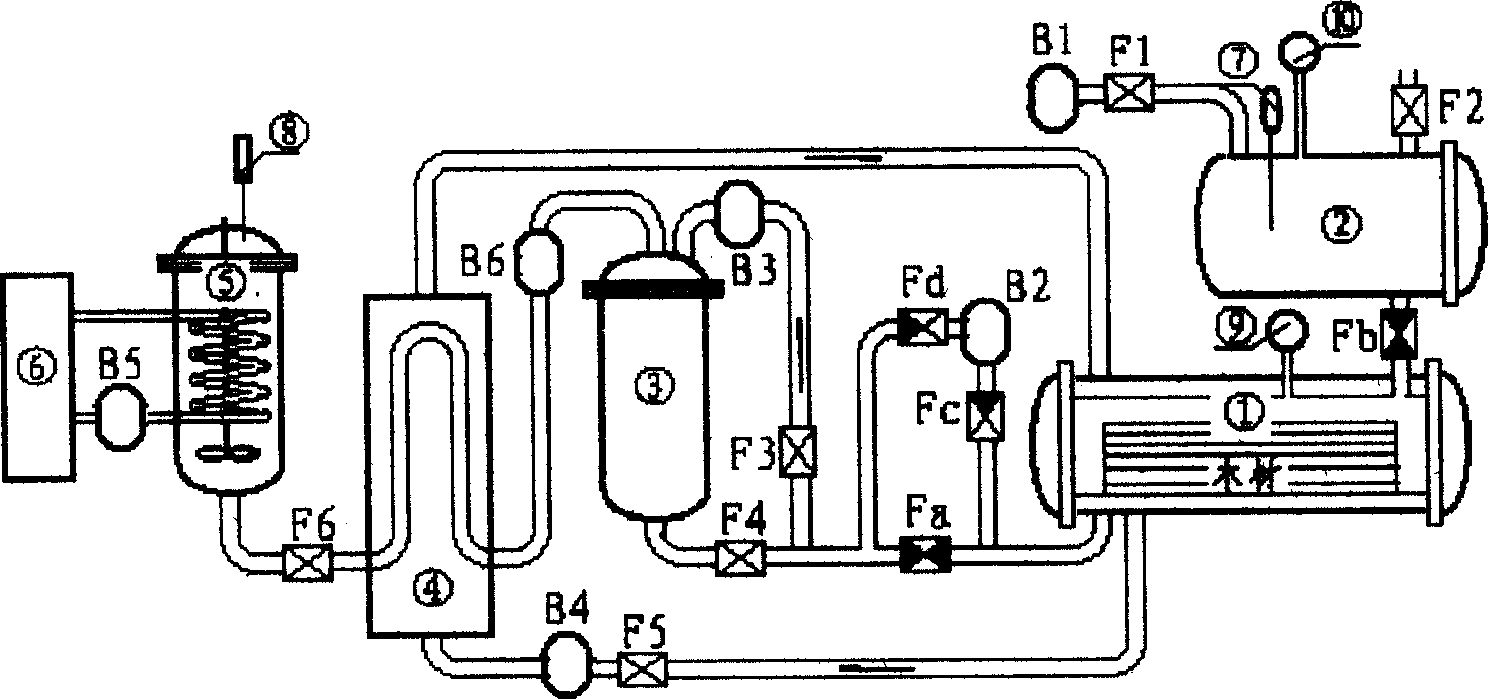

[0022] exist figure 1 The hot water in the medium hot water boiler ⑥ is driven by the hot water circulation pump B5 to circulate in the coil in the reaction kettle ⑤, heating the components of the impregnating solution in the reaction kettle ⑤ to make it quickly dissolve and react. The process thermometer ⑧ displays the temperature of the impregnation solution in the reaction kettle ⑤.

[0023] The dissolution temperature of each component of the impregnation solution is not allowed to exceed 50°C

[0024] raw material name

100% (weight)

illustrate

Formaldehyde HCHO

58.80

Formaldehyde: urea = 1: 1.66

(weight ratio)

Urea CO(NH 2 ) 2 .

(Resorcinol C 6 h 6 o 2 )

35.30

(1~5)(see description)

Hexamethylenetetramine C 6 h 12 N 4

0.90

Hardener

0.80 (20% solution)

Hardener

Melamine C 3 h 6 N 6

1.00(1~5%)

Formalde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com