Pure static state double heating apparatus for crystal growth by temperature gradient technique

A technology of crystal growth and double heating, which is applied in the field of crystallization technology, can solve the problems of thermal insulation shield damage, failure to grow crystals, etc., and achieve the effect of good thermal field stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

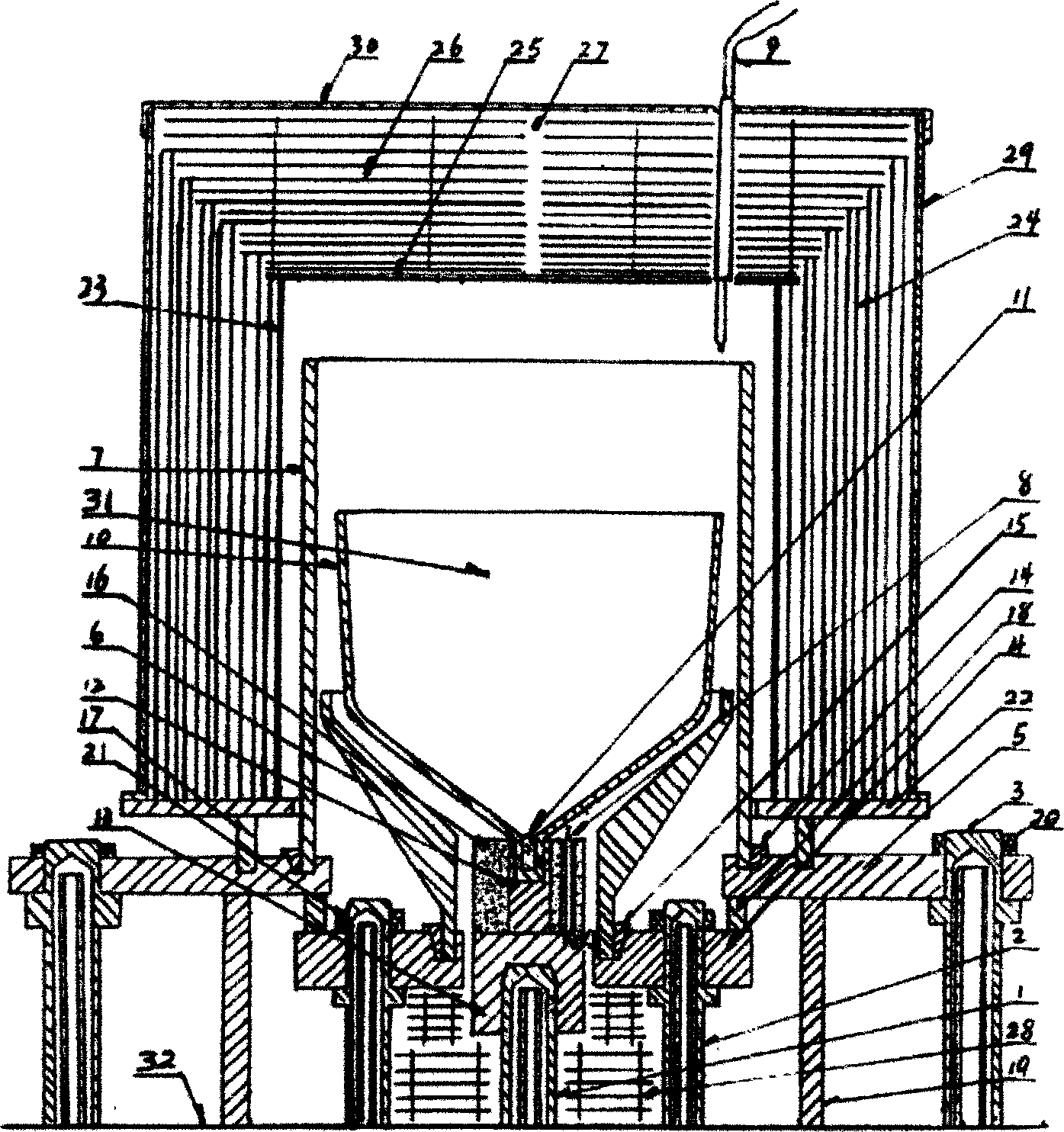

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0013] Such as figure 1 In the shown pure static double heating temperature gradient method crystal growth device, 4 electrode rods, 2 auxiliary electrode rods and 2 main electrode rods 3 are arranged on the chassis 33 of the bell-type high vacuum single crystal furnace. The electrode rods 2 and 3 are cooled by water to ensure that the electrode rods 2 and 3 are in insulated and sealed contact with the chassis 32 of the single crystal furnace through the high temperature resistant polyvinyl fluoride and the sealing ring.

[0014] In order to reduce the temperature difference between the upper end of the molybdenum crucible 10 and the seed crystal 11, an auxiliary heating element 6 with an inverted conical shaped strip is provided under the crucible 10, and the auxiliary heating element 6 is tightly pressed on the annular trapezoid by the auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com