Epoxy modified unsaturated polyester resin special for putty and method for making same

An epoxy-modified resin, epoxy-modified technology, applied in the direction of filling slurry, etc., can solve the problems of poor shock resistance, poor overall adhesion, and poor grinding, and achieve good chemical resistance, strong adhesion, easy to use. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

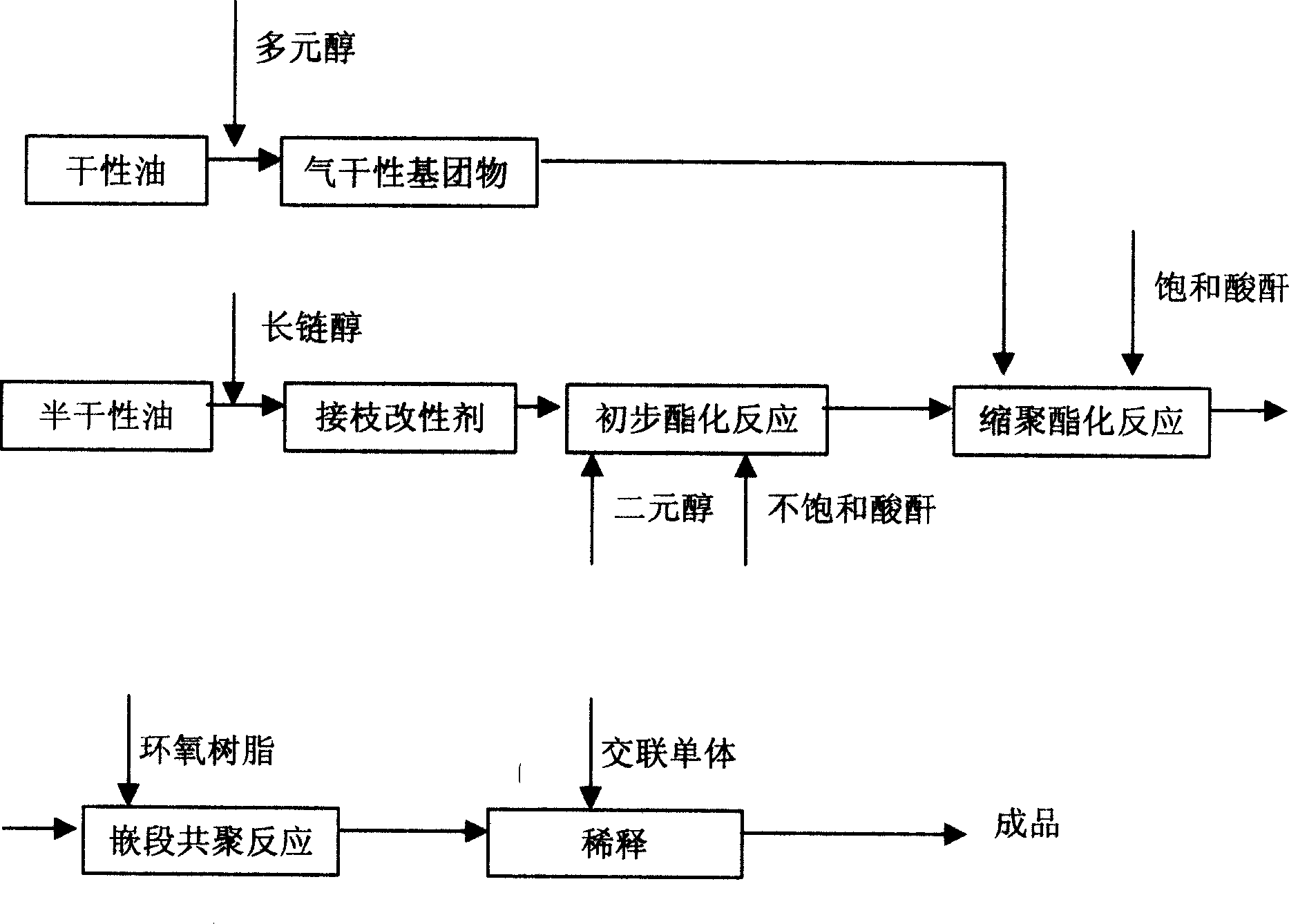

[0067] Produce product of the present invention according to formula 1 listed in table 1 according to the following steps:

[0068] Step 1: reacting glycerol and linseed oil according to the conventional method of alkyd resin to obtain monoglyceride air-drying groups;

[0069]Step 2: reacting 1-6 hexanediol with catalpa oil according to the conventional method of alkyd resin to obtain a monoglyceride graft modifier;

[0070] Step 3: put the grafting modifier prepared in step 2, unsaturated acid anhydride and glycol into the reaction equipment with stirring, and react at a constant temperature at 170-180°C for about 2 hours, and the acid value reaches 300-340mgKOH / g Afterwards, the initial esterification reaction product was obtained;

[0071] Step 4: Add unsaturated acid anhydride and air-drying radicals prepared in step 1 to the reactant prepared in step 3, and react at a constant temperature of 190-205°C for about 3 hours, and the acid value reaches about 150-200mgKOH / g Af...

Embodiment 2

[0074] According to the embodiment listed in the production steps in Example 1, the difference is that the crosslinkable monomer used is a mixed solution of styrene and p-methylstyrene. The polyhydric alcohol is pentaerythritol. The drying oil is tung oil, and the semi-drying oil is palm oil. The molecular weight, acid value, solid content, and 25°C curing time of the obtained product are listed in Table 2.

Embodiment 3

[0076] According to the production steps of Example 1 and the formula of Example 3 listed in Table 1, the difference is that the crosslinkable monomer used is a mixed solution of styrene and vinyltoluene. The drying oil is tung oil, and the semi-drying oil is soybean oil. The molecular weight, acid value, solid content, and 25°C curing time of the obtained product are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com