Precast light insulation composite wall panel

A thermal insulation composite and light-weight technology, which is applied in the direction of building components, buildings, building structures, etc., can solve problems such as large thermal conductivity, thermal bridges, troublesome construction, etc., achieve small thermal conductivity, increase bonding force, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

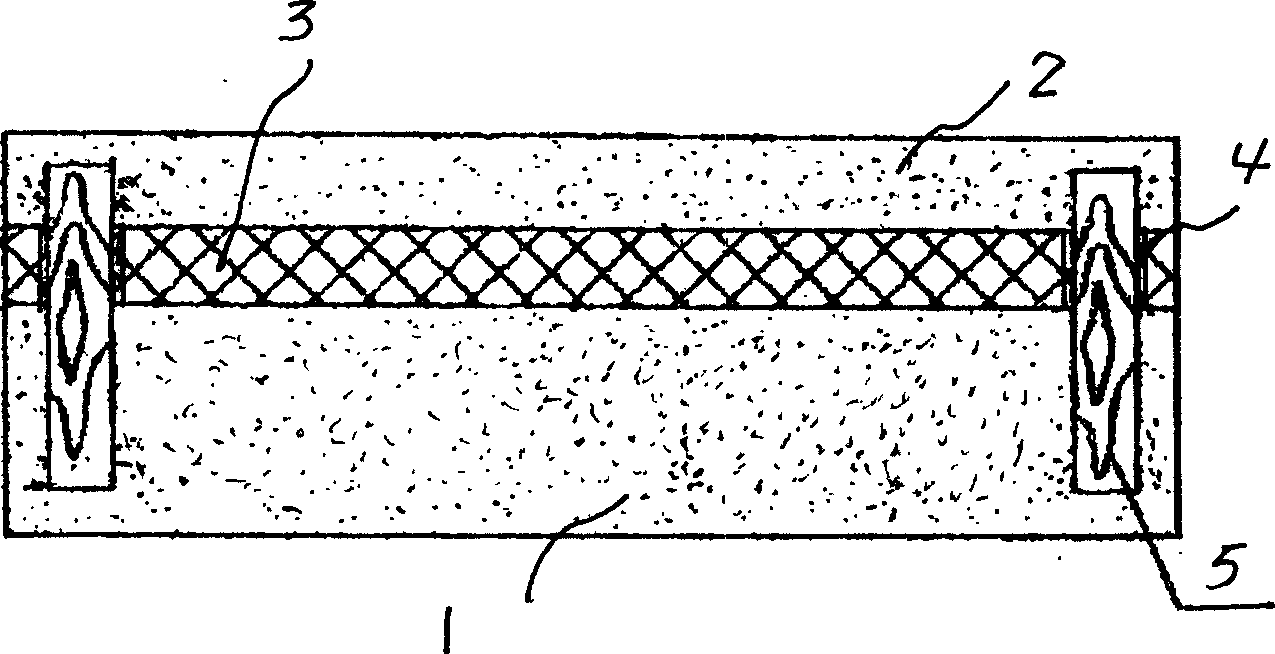

Embodiment 1

[0035] a. Take by weight percentage 44 kilograms of known Sorel (Sorel) cement, 31.5 kilograms of fly ash, 19.8 kilograms of light aggregate, 2.2 kilograms of reinforcing materials, and 2.5 kilograms of stabilizers. Among them, the fly ash should meet the technical requirements of GB1596 for Class III fly ash; the light aggregate can be a combination of EPS particles, rice husks, sawdust, light volcanic ash, water-increased perlite, and plant fibers (straw, wheat straw, etc.) one or several kinds; the reinforcing material is ordinary glass fiber or chopped polypropylene fiber; the stabilizer is sulfuric acid or oxalic acid, and the weighed raw materials are placed in a concrete mixer and stirred evenly; of course, the currently disclosed light, High-strength base material;

[0036] b. Inject the uniformly stirred material into the mould, tap it firmly and flatten it to form the substrate 1 blank;

[0037] c. Place the thermal insulation partition 3 on the substrate 1 blank, t...

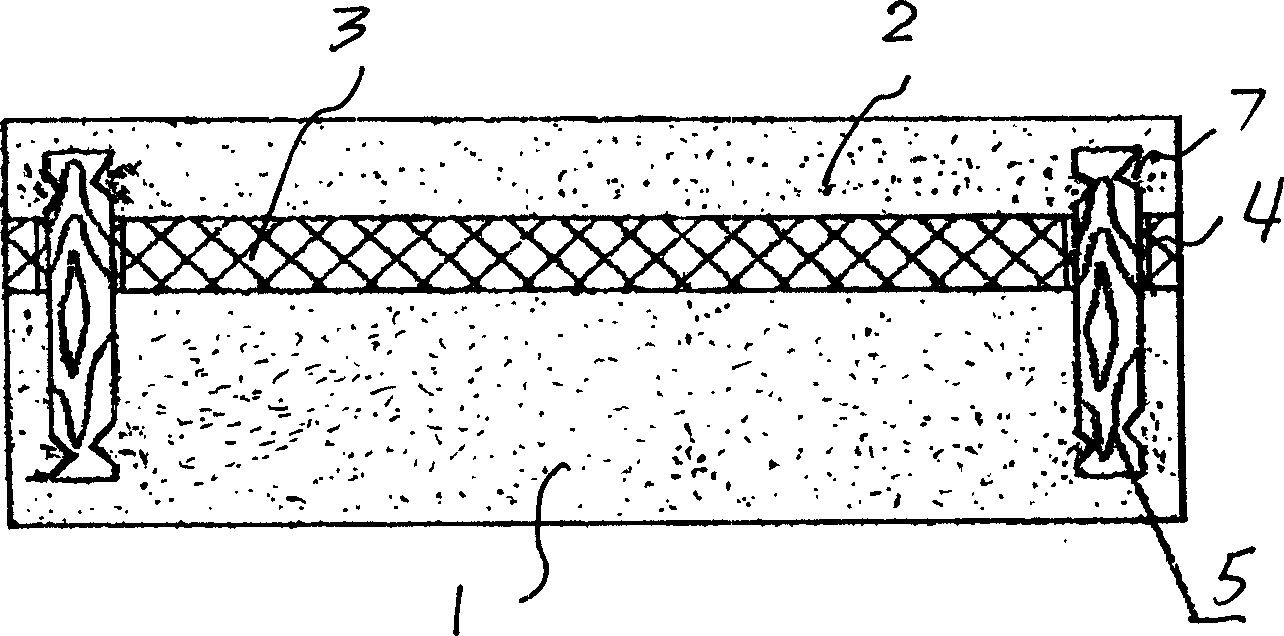

Embodiment 2

[0041] a. take by weight percentage 41 kilograms of known Sorel (Sorel) cement, 25.5 kilograms of fly ash, 25 kilograms of light aggregate (wherein sawdust 15 kilograms, increase water perlite 10 kilograms), glass fiber 2.2 kilograms, 1.8 kilograms of sulfuric acid, the weighed raw materials are placed in a concrete mixer and stirred evenly;

[0042] b. Inject the uniformly stirred material into the mould, tap it firmly and flatten it to form the substrate 1 blank;

[0043] c. Place the insulation partition 3 on the substrate 1 blank, use Figure 4 The shown diameter is 25 ~ 35mm, and the cylindrical hard miscellaneous wood reinforcing rib 5 with grooves 7 on the left and right sides of the upper and lower ends passes through the hole 4 on the insulation partition 3, and its end and the groove 7 at the lower end are inserted into the base plate 1 In the blank, the centerlines of the grooves 7 on the left and right sides are preferably not on the same straight line, and the th...

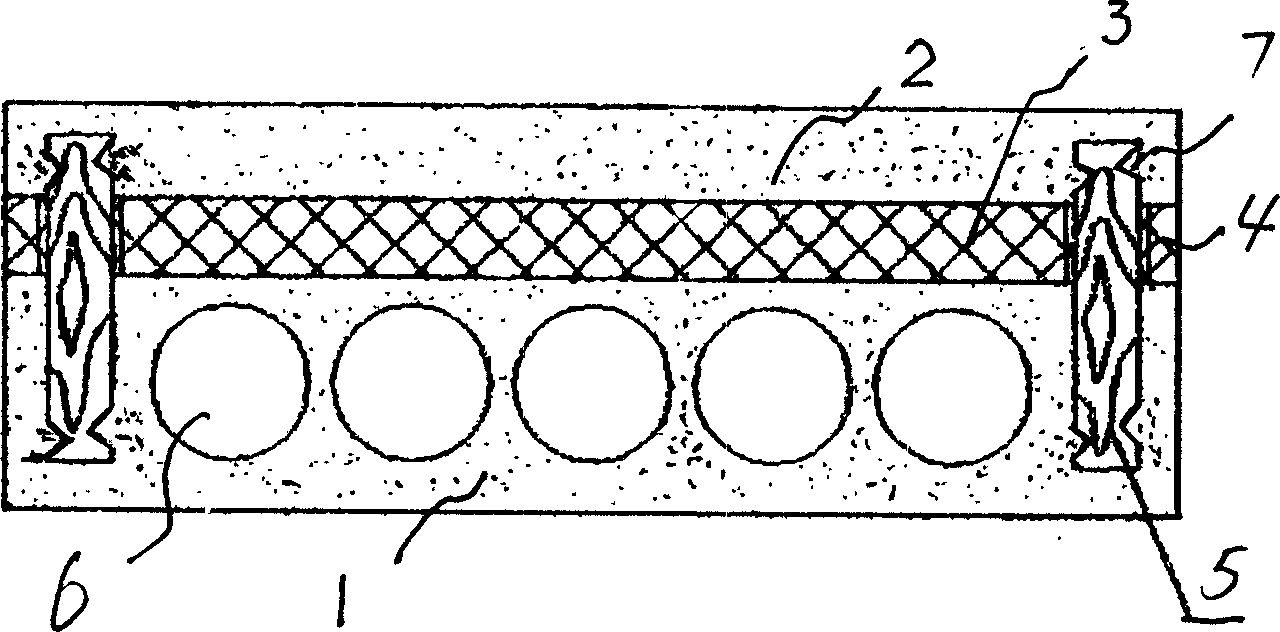

Embodiment 3

[0047] a. Weigh 42 kilograms of known Sorel cement, 33.2 kilograms of fly ash, 20.8 kilograms of light aggregate (including 0.8 kilograms of EPS particles and 10 kilograms of rice husks), 2.0 kilograms of glass fiber, and 3.5 kilograms of oxalic acid by weight percentage. kg, put the weighed raw materials in a concrete mixer and stir evenly;

[0048] b. Pour the evenly stirred material into the mold. The mold is composed of a side mold and an end mold. There is a mold hole for inserting the core tube on the end mold. The side mold and the end mold are connected by bolts, and they are pressed firmly to form a thickness of 110-150mm. Base plate 1 blank, ribs 5 can be set according to the area of base plate 1, generally 6-8 can be set;

[0049] c. Place the insulation partition 3 on the substrate 1 blank, use Figure 4 The cylindrical reinforcing rib 5 with a diameter of 25-35mm and grooves 7 on the left and right sides of the upper and lower ends passes through the hole 4 on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com