Method for preparing titanium dioxide mesoporous material

A technology of titanium dioxide and mesoporous materials, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor thermal stability, complicated preparation process, inability to generate photo-generated holes and photo-generated electrons, etc. Stability and photocatalytic activity, the effect of broadening the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 3.2g template agent series block copolymer EO 20 PO 70 EO 20 Dissolve in 15mL of n-butanol, and then add 7.5mL of tetrabutyl titanate. After stirring for 3 h, 0.04 g of La(NO 3 ) 3 ·nH 2 O, 1.4 mL of hydrochloric acid, 1.9 mL of water in 15 mL of butanol were added dropwise to the above solution. After the dropwise addition was completed, stirring was continued for 3h. The obtained sol was poured into a Petri dish and aged at room temperature for 48 h. Then continue aging at 40°C for 48h, and then aging at 150°C for 12h. The obtained xerogel was ground for use.

[0035] Take 2 g of the obtained xerogel, and program the temperature in the air flow, 1 ° C min -1 , to 400 ℃ and then keep warm for 5h. Then at 10°C min -1 Cool down to room temperature. 0.70 g of white solid powder was obtained.

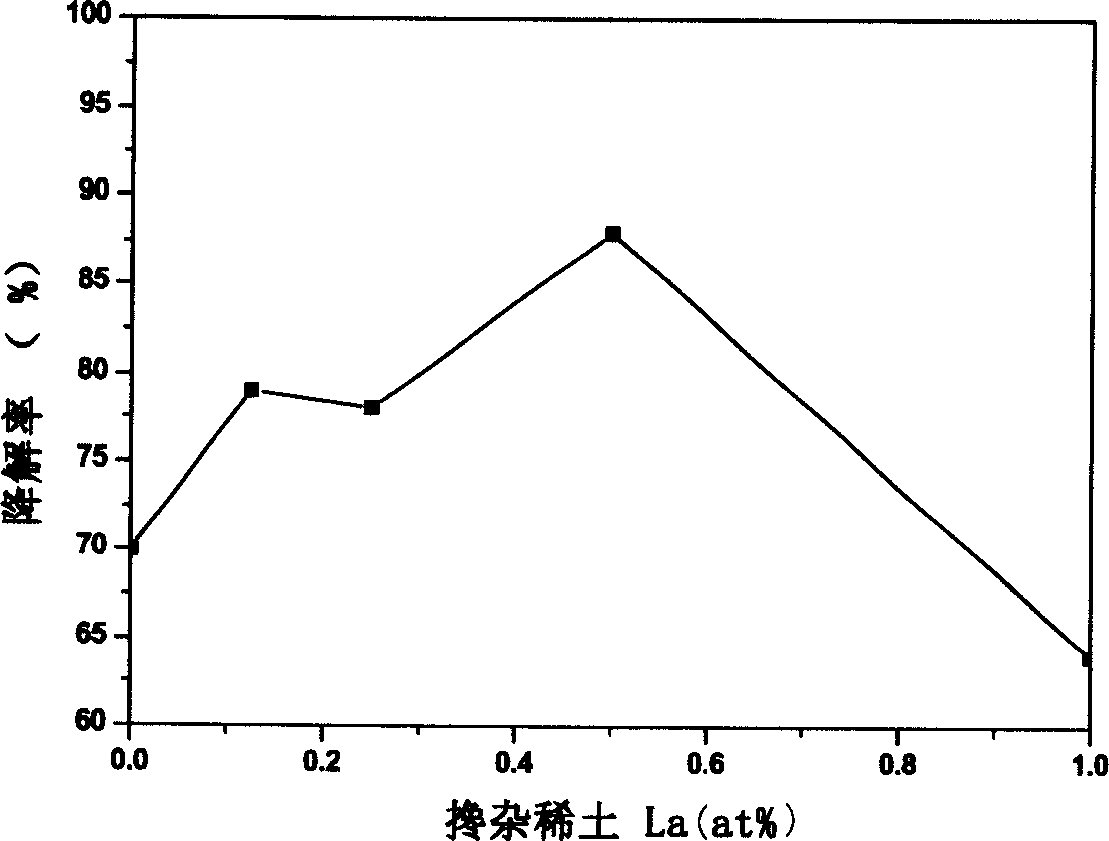

[0036] Take 0.5g of the obtained catalyst, use a UV lamp with a cooling water jacket and a power of 300 watts as a light source, and degrade 50mL of concentration to 20...

Embodiment 2

[0038] 3.2g template agent series block copolymer EO20 PO 70 EO 20 Dissolve in 12 mL of isopropanol, and then add 6.3 mL of isopropyl titanate. After stirring for 3 h, 0.08 g of La(NO 3 ) 3 ·nH 2 O, 1.4 mL of hydrochloric acid, 1.9 mL of water in 12 mL of isopropanol were added dropwise to the above solution. After the dropwise addition was completed, stirring was continued for 3h. The obtained sol was poured into a petri dish and aged at room temperature for 36 h. Then continue aging at 60°C for 24h, and then aging at 130°C for 24h. The obtained xerogel was ground for use.

[0039] Take 2 g of the obtained xerogel, and program the temperature in the air flow, 1 ° C min -1 , to 450 ℃ and then keep warm for 3h. Then at 10°C min -1 Cool down to room temperature. 0.68 g of white solid powder was obtained.

Embodiment 3

[0041] 1.5g template agent series block copolymer EO 106 PO 70 EO 106 Dissolve in 10mL ethanol, then add 5.0mL tetraethyl titanate. After stirring for 3 h, 0.02 g of La(NO 3 ) 3 ·nH 2 O, 1.4 mL of hydrochloric acid, 1.9 mL of water in 10 mL of ethanol were added dropwise to the above solution. After the dropwise addition was completed, stirring was continued for 3h. The obtained sol was poured into a Petri dish and aged at room temperature for 24 h. Then continue aging at 50°C for 36h, and then aging at 120°C for 36h. The obtained xerogel was ground for use.

[0042] Take 1.5 g of the obtained xerogel, and heat it up in an air stream at 1°C min -1 , to 550 ℃ and then keep warm for 1h. Then at 10°C min -1 Cool down to room temperature. 0.52 g of white solid powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com