High intensity discharge lamp ballast apparatus

A technology for lighting devices and discharge lamps, applied in the use of discharge lamps and gas discharge lamps, lighting devices, etc., which can solve the problems that hinder the small size and low cost of high-intensity discharge lamp devices, increase the price of circuit components, transformers and capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below.

[0024] Embodiment 1

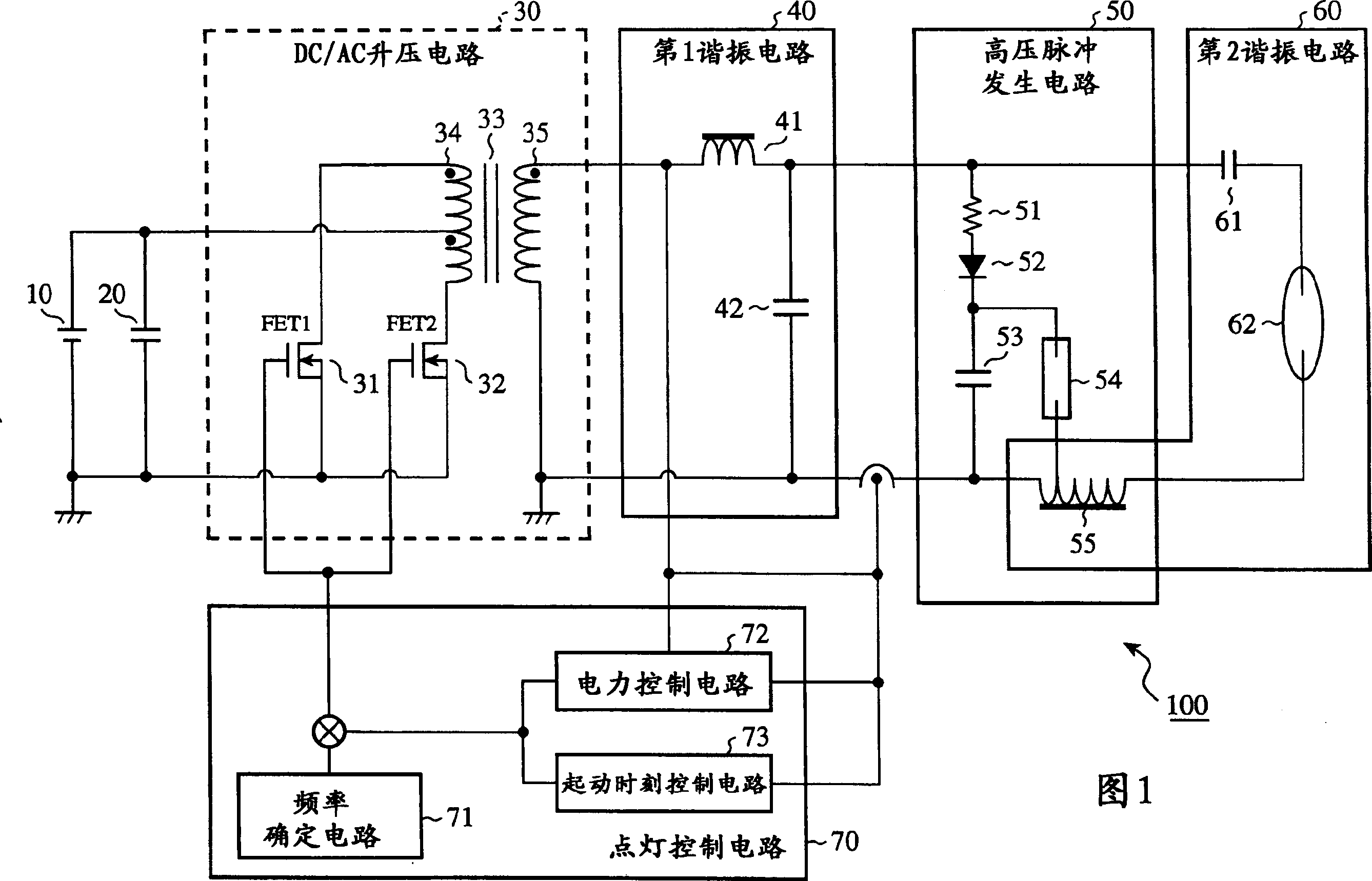

[0025] FIG. 1 is a circuit diagram showing the configuration of a metal halide lamp lighting device 100 (high intensity discharge lamp lighting device) according to Embodiment 1. As shown in FIG. As shown in the figure, the metal halide lamp lighting device 100 includes a DC power source 10 such as a storage battery, a smoothing capacitor 20, a DC / AC step-up circuit 30 (DC / AC inverter), a first resonance circuit 40, a high-voltage pulse generator 50, The second resonant circuit 60 and the lighting control circuit 70 .

[0026] The DC / AC step-up circuit 30 includes FETs (Field Effect Transistors) 31 and FETs 32 (switching elements), and a DC / AC converter transformer 33 (transformer). The FET31 and FET32 are alternately turned on and off by a pulse signal input to the gate from the lighting control circuit 70 . As a result, the current flowing through the primary winding 34 of the DC / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com