Base plate treater

A substrate processing device and substrate technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, optics, etc., can solve the problems of low object detection accuracy, inability to set delay time, poor coating, etc., to prevent Reduced detection accuracy, prevent false detection, and realize the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The preferred implementation forms of the present invention will be described in detail below with reference to the accompanying drawings.

[0060] 1. The first form of implementation

[0061] 1.1. Description of composition

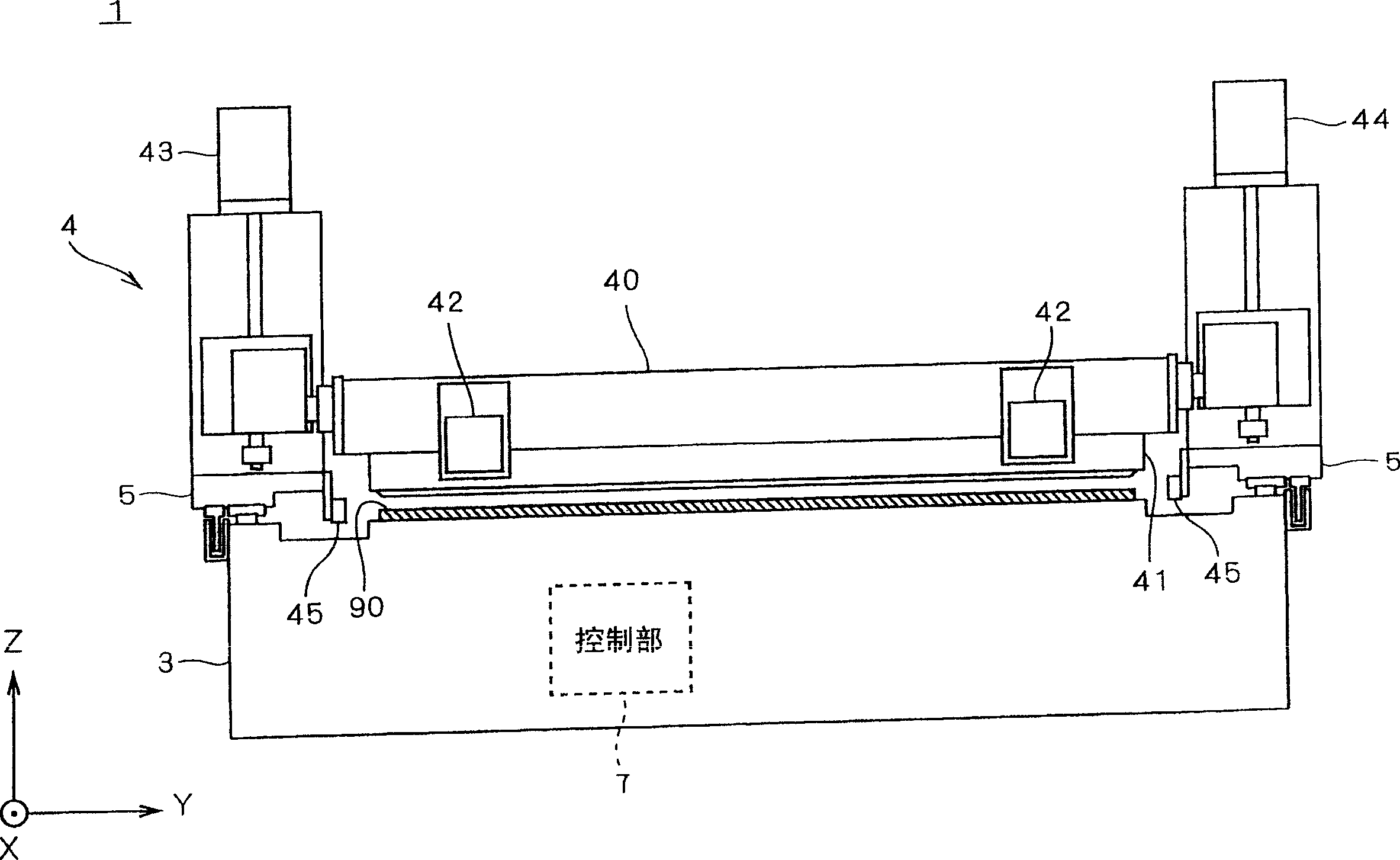

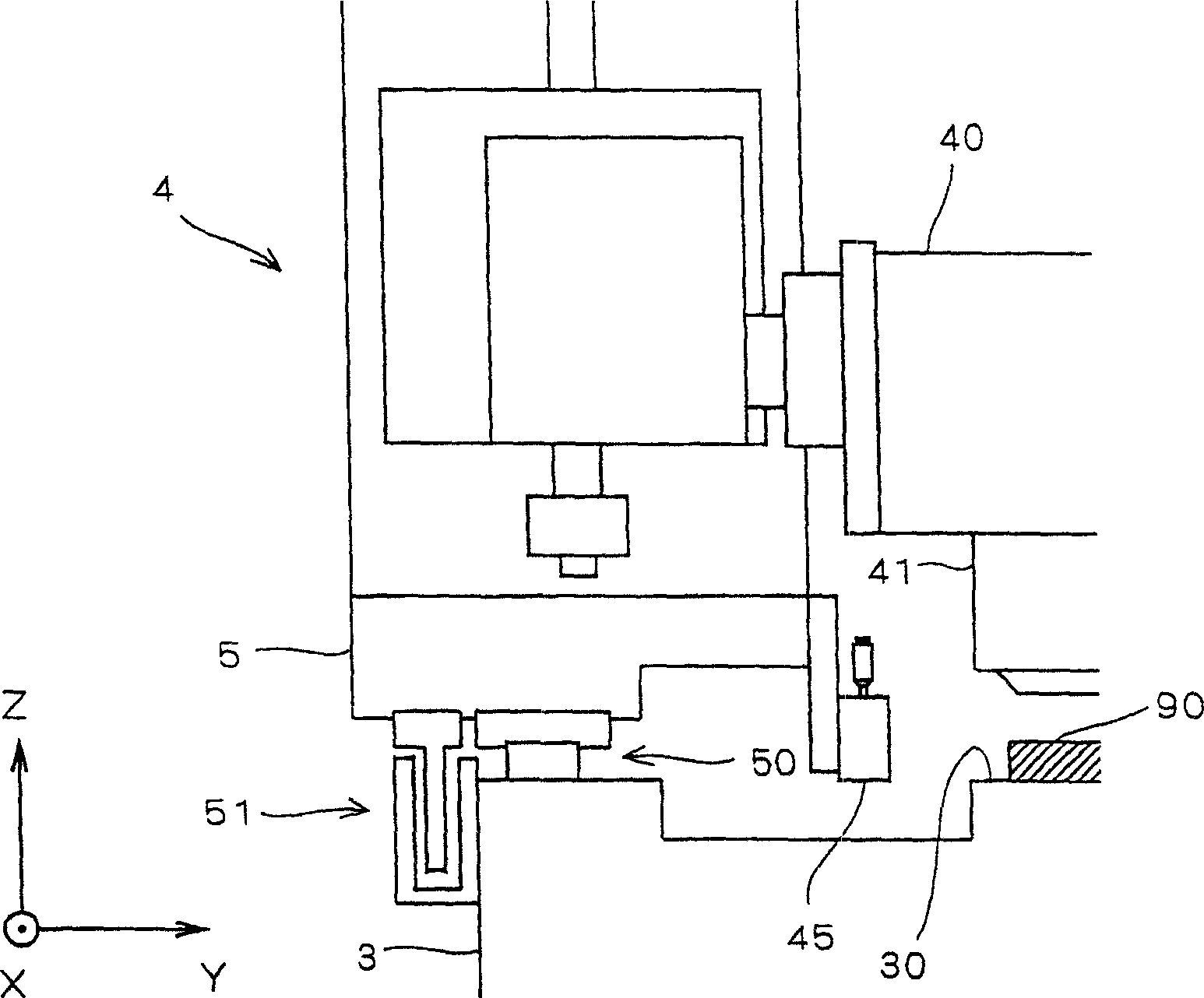

[0062] figure 1 It is a front view of the substrate processing apparatus 1 according to the first embodiment of the present invention. figure 2 It is an enlarged view of the peripheral portion of the detection sensor 45 of the substrate processing apparatus 1 . in addition, figure 1 and figure 2 Among them, for the convenience of illustration and description, it is defined that the Z-axis direction represents the vertical direction, and the XY plane represents the horizontal plane. They are defined for convenience in order to grasp the positional relationship, and are not limited to the directions described below. The following figure is also the same.

[0063] A square glass substrate used for manufacturing a screen panel of a liquid cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com