Oil sensor placement structure of engine

A technology for configuring structure and engine oil, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of difficulty in ensuring the required space, and achieve the effect of preventing the detection accuracy from being reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Figure 1 to Figure 8 The first embodiment of the present invention is shown.

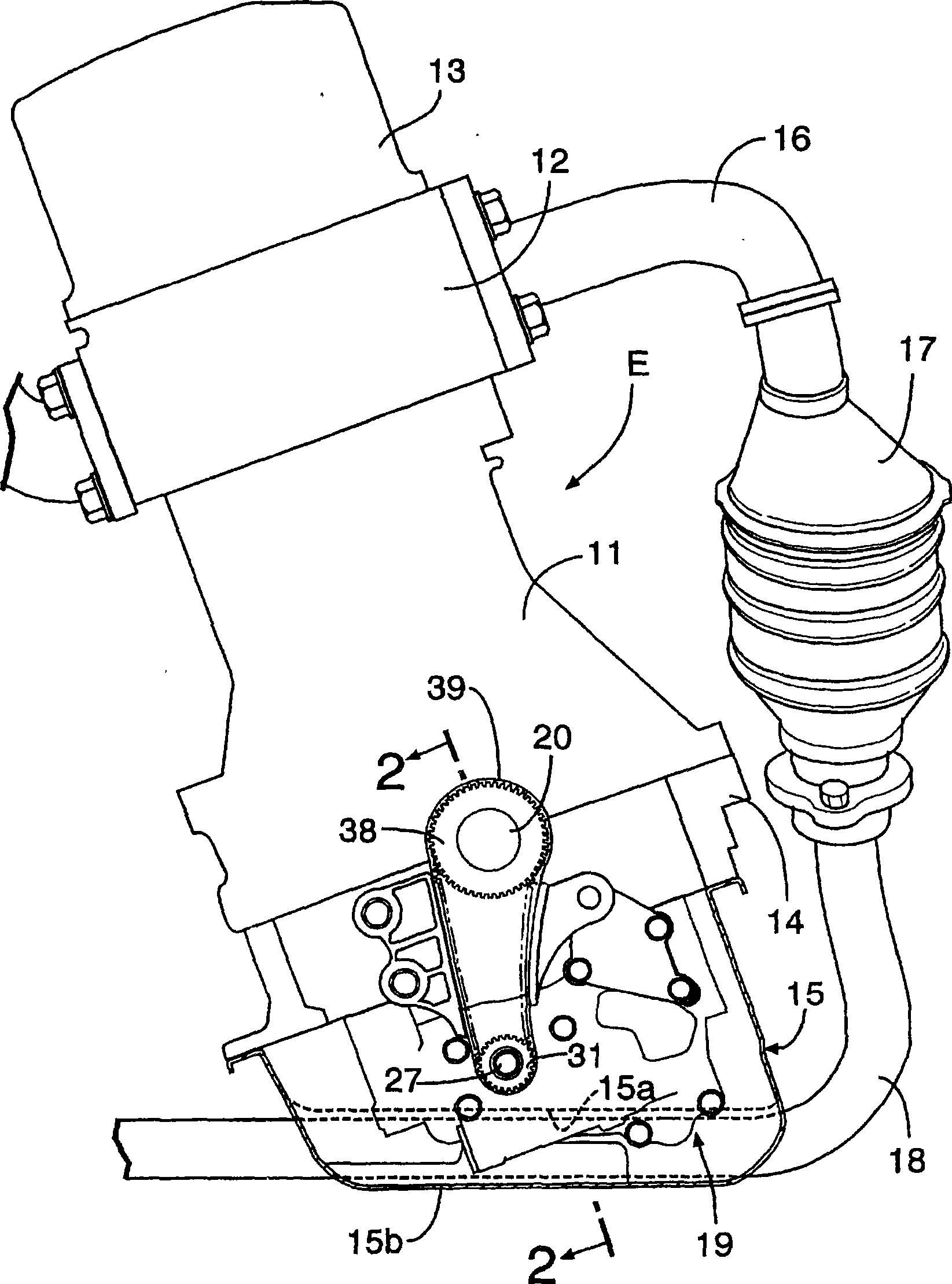

[0055] Depend on figure 1 As can be seen, the cylinder block 11 of the diesel engine E mounted horizontally in the engine room of a motor vehicle has a cylinder head 12 and a cylinder head cover 13 coupled to its upper portion, and a crankcase 14 and an oil pan 15 coupled to its lower portion. The exhaust pipe 18 connected to the exhaust manifold 16 via the DPF (diesel particulate filter) 17 passes through the lower surface of the oil pan 15 and extends to the rear of the vehicle body. The exhaust manifold 16 combines On the front surface of the cylinder head 12 . A secondary balancer device 19 for reducing secondary vibration of the engine E is provided between the lower surface of the cylinder block 11 and the oil pan 15 . The crankshaft 20 is rotatably supported on a dividing surface between the cylinder block 11 and the crankcase 14 .

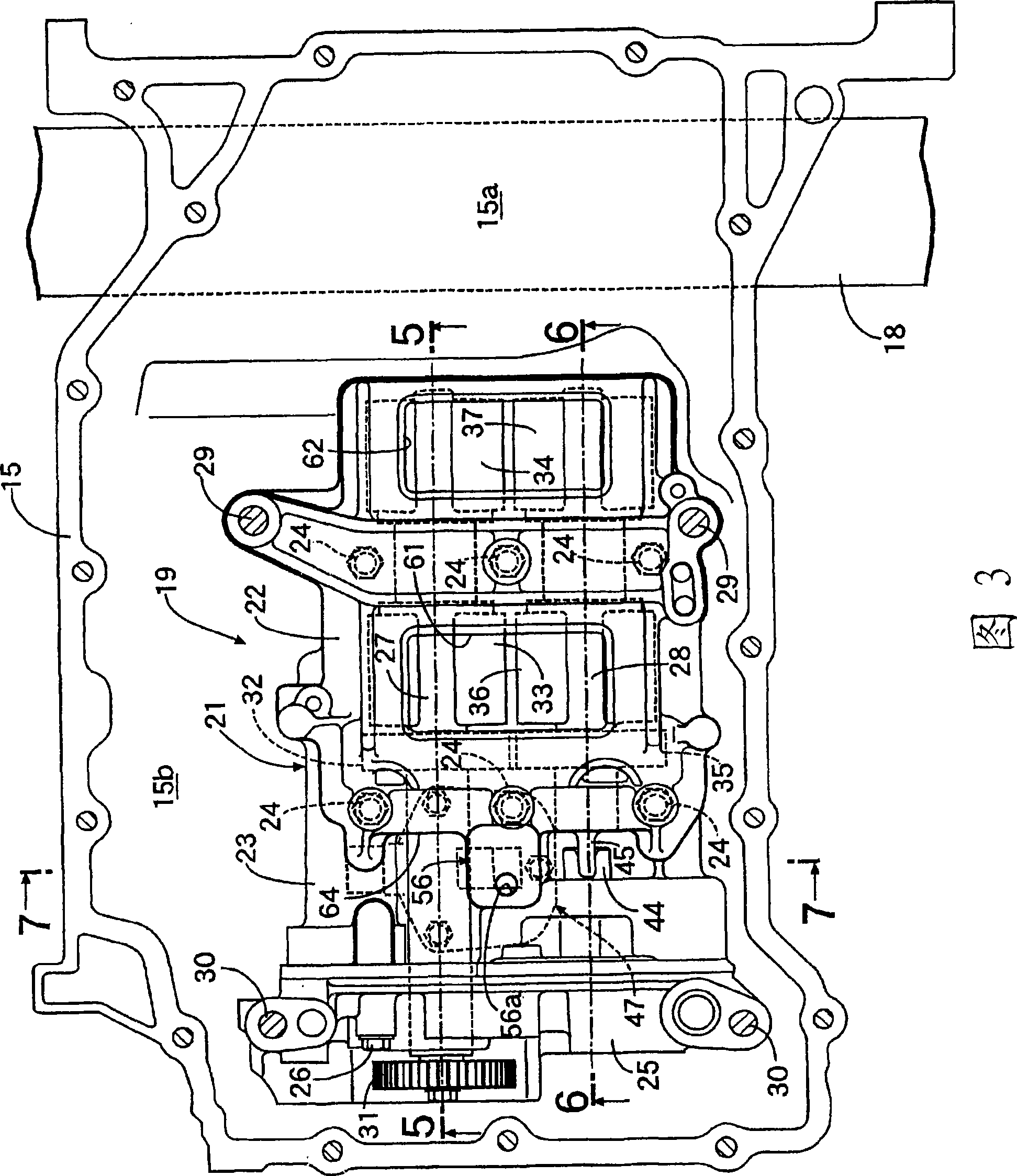

[0056] Next, the configuration of the secondary...

Embodiment 2

[0077] Next, a second embodiment of the present invention will be described with reference to FIG. 9 .

[0078] In the first embodiment, the shielding portion 56 is integrally formed with the upper case 22 , but in the second embodiment, the shielding portion 56 is constituted as an independent component, and is assembled to the lower case of the balancer case 21 with bolts 57 , 57 . The lower surface of the opening 65 of 23. The shielding portion 56 is a cylindrical member tapered from the lower portion toward the upper portion, and covers substantially the entire sensing portion 49 of the oil level sensor 47 protruding into the oil pan 15 .

[0079]In this manner, by covering substantially the entirety of the sensor portion 49 with the shield portion 56 , the influence of the splash of engine oil can be more reliably eliminated, and the detection accuracy of the oil level sensor 47 can be further improved. In addition, when the oil pan 15 is detached from the crankcase 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com