Wind speed sensor based on micro mechanic working and its producing method

A wind speed sensor and micromachining technology, which is applied in the direction of measuring fluid velocity using thermal variables, can solve the problems of large thermal coupling, affect sensor sensitivity, and high cost, and achieve the effects of small lateral heat transfer, improved sensitivity, and simple packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

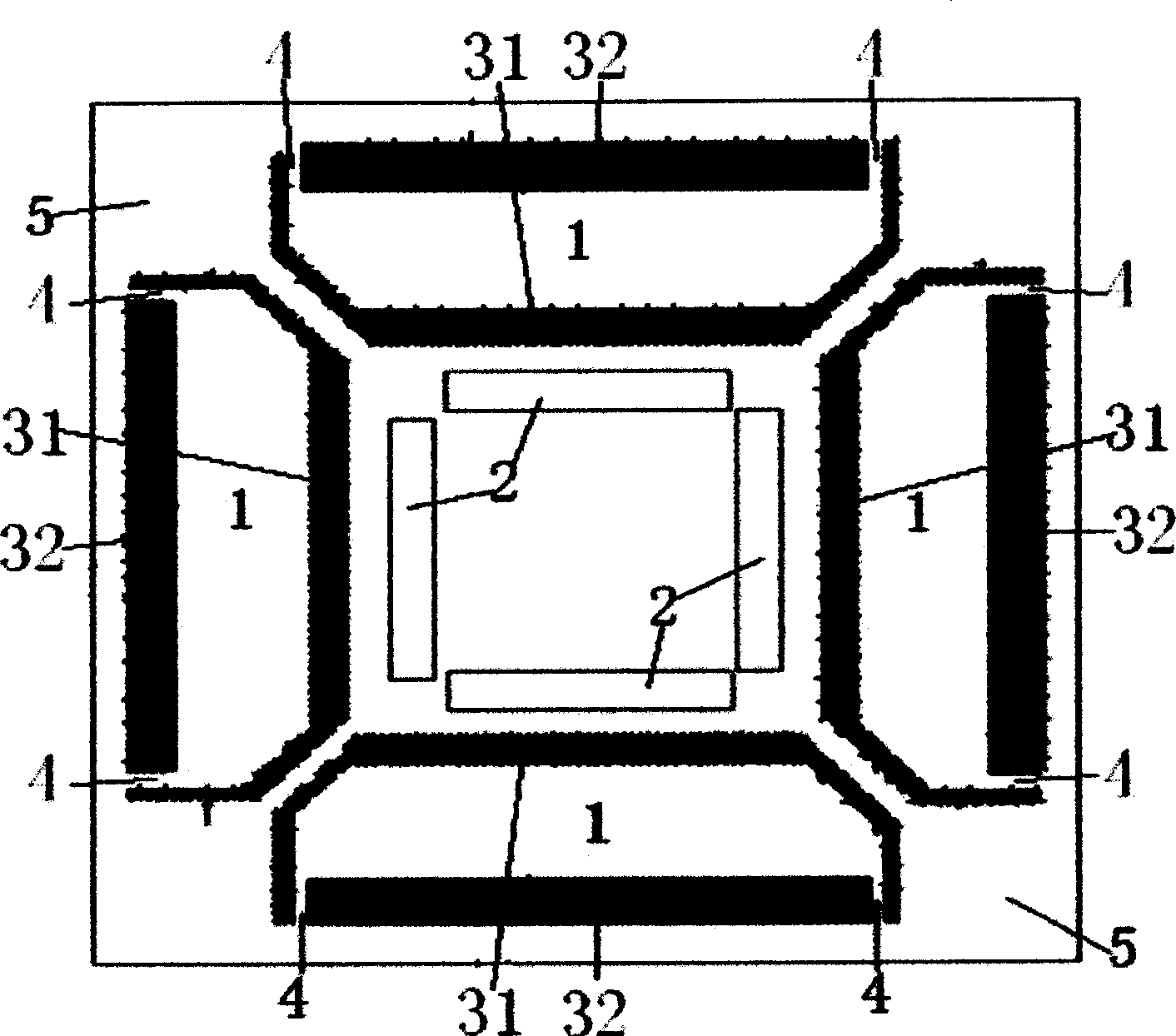

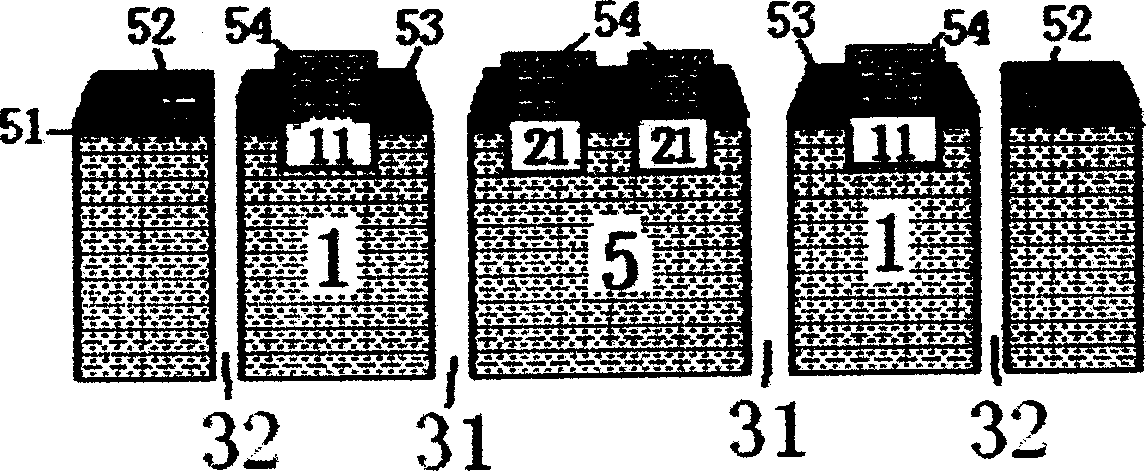

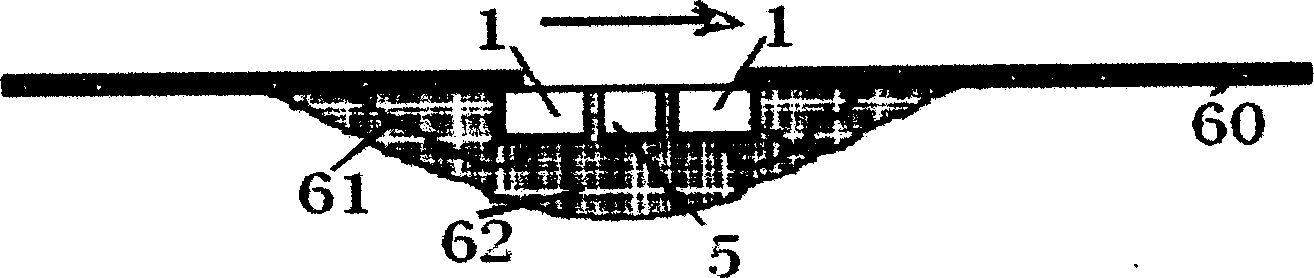

[0022] The invention is a miniature wind speed sensor sensitive to wind speed and wind direction signals. The entire structure of the sensor is integrated on the silicon substrate 5, and the central part is composed of four rectangular heating strips 2 forming a square, and there are bulk silicon temperature measuring resistors 1 symmetrically distributed outside each heating strip 2, and the bulk silicon temperature measuring resistors 1 and the heating bar 2 are provided with an inner ICP groove 31, and an outer ICP groove 32 is arranged outside the bulk silicon temperature measuring resistor 1, and the bulk silicon temperature measuring resistor 1 passes through the narrow silicon 4 with very narrow ends and the entire silicon substrate 5 connection; the inner ICP groove 31 between the heating strip 2 and the bulk silicon temperature measuring resistor 1 serves as thermal isolation. An oxide layer 51 is provided on the upper surface of the silicon substrate 5, and a layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com