Explosion welding method for low melting point metal composite plate

A low-melting-point metal, explosive welding technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of complicated explosive welding process, increase the number of explosive welding, decrease processing output, etc., and reach the welding parameter range. The effect of increasing and reducing the cost of explosive welding and increasing the upper limit of explosive welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

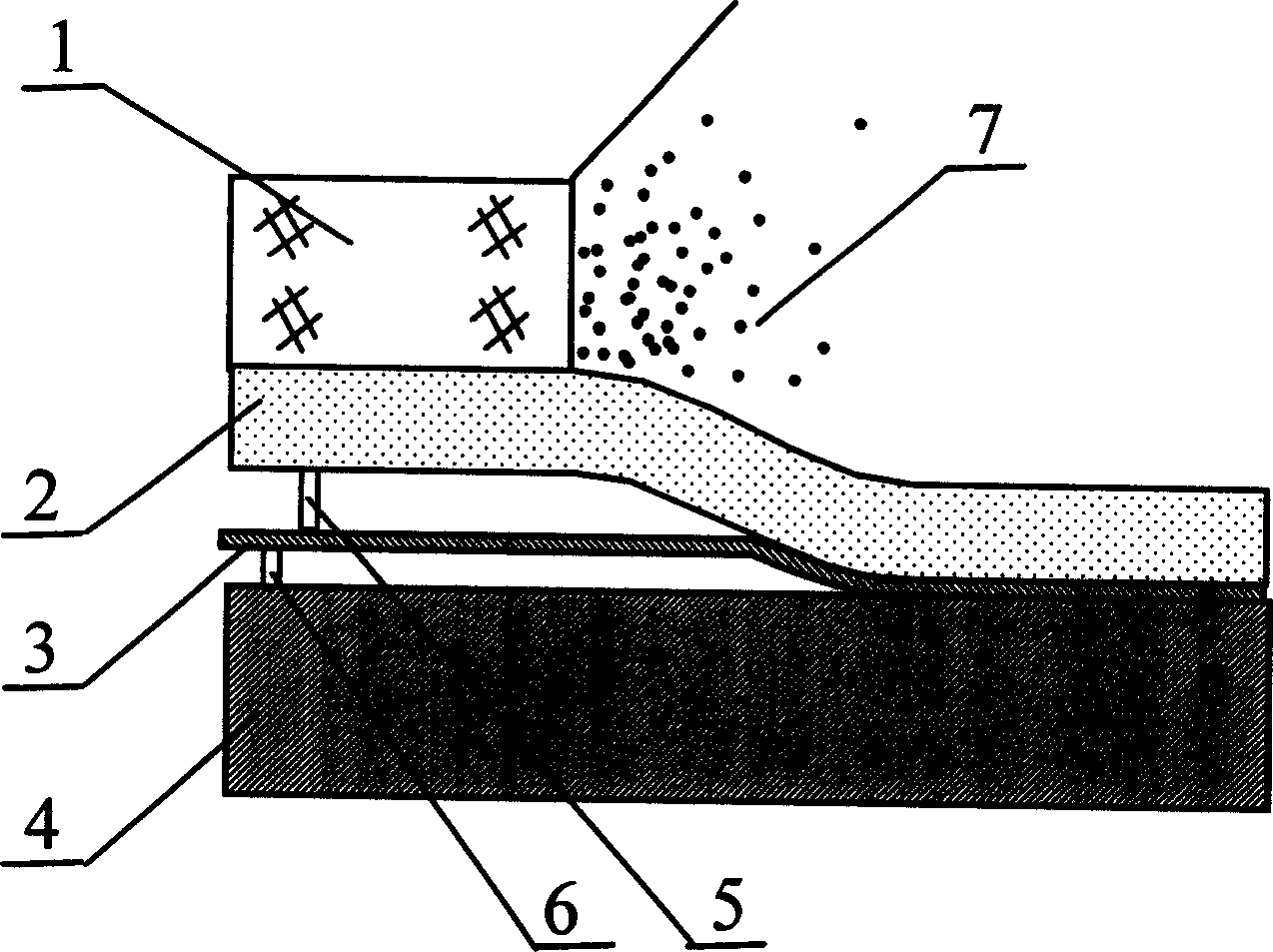

Embodiment 1

[0011] Explosive welding of aluminum-steel composite panels is carried out according to the layout of the attached drawings. The thickness of the L2 pure aluminum cladding 2 is 29 mm, the intermediate transition thin plate layer 3 is made of 1 mm ordinary steel plate, and the base plate 4 is 40 mm ordinary carbon steel plate. Explosive 1 uses 40mm thick granular ammonium oil explosives with a density of 0.85g cm -3 , adjust the detonation velocity at 2100~2300m·s -1 , the upper shelf height 5 is 8mm, and the lower shelf height 6 is 2mm. After explosive welding, the sample is cut for tensile strength test. The interface is firmly bonded, the fracture appears on the aluminum side, and the interface tensile strength is greater than 83MPa. In contrast, in the explosive welding without the transition thin steel plate 3, the base cladding plate completely bounced off after the explosion, and no welding was formed.

Embodiment 2

[0013] According to the explosive welding parameters of Example 1, the intermediate transition thin plate 3 was replaced with a 1.5mm copper plate, and the interface strength was checked after the explosive welding. The fracture appeared on the aluminum side, and the interface tensile strength was greater than 83MPa.

Embodiment 3

[0015] According to the explosive welding parameters of Example 1, the intermediate transitional thin plate 3 was replaced with a 0.5mm plain carbon steel plate, and the interface strength was checked after the explosive welding. The fracture appeared on the aluminum side, and the interface tensile strength was greater than 83MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com