Anion reacting water polyurethane flame-proof finishing agent and preparing method thereof

A technology of water-based polyurethane and flame retardant finishing agent, which is applied in the field of anionic reactive water-based polyurethane flame retardant finishing agent and its synthesis, can solve the problems of complex, difficult and difficult flame retardant of polyester/cotton, and achieve physical and mechanical properties. Small change and remarkable flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

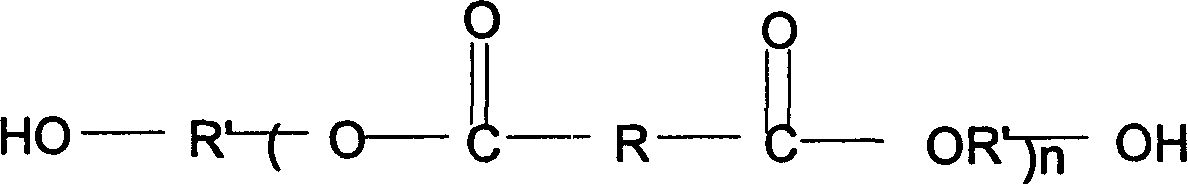

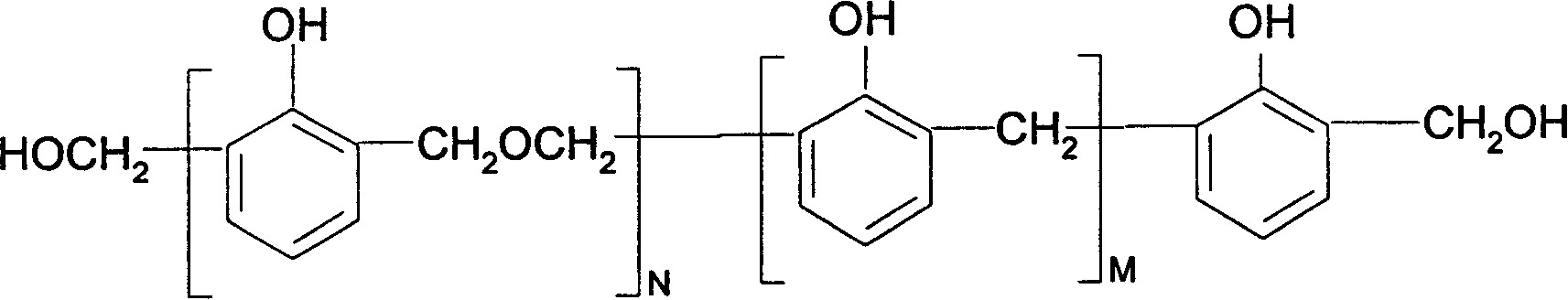

Method used

Image

Examples

Embodiment 1

[0063] 1. In a 500ml four-neck flask, add 10g of polyoxypropylene triol, 20g of flame retardant polyol compound, add 5g of isophorone diisocyanate after vacuum dehydration, and react at 120°C for 5 hours under the protection of nitrogen to prepare Obtain polyurethane prepolymer, -NCO content 4.2%.

[0064] 2. In a 500ml four-neck flask, add 5g of methyl ethyl ketone, stir for 10 minutes, add 40ml of sodium bisulfite aqueous solution and 40ml of tert-butanol for emulsification, add hydrochloric acid after 1 hour, adjust the pH to 3~4, and the solid content is 35% .

Embodiment 2

[0066] 1. In a 500ml four-neck flask, add 9g of polyoxypropylene diol, 17g of flame retardant polyol compound, add 8g of hexamethylene diisocyanate (HDI) after vacuum dehydration, and react at 120°C under nitrogen protection After 6 hours, a polyurethane prepolymer was prepared with a -NCO content of 3.4%.

[0067] 2. In a 500ml four-necked flask, add 5g of acetone, stir for 10 minutes, add 40ml of sodium bisulfite aqueous solution and 50ml of isopropanol for emulsification, add hydrochloric acid after 1 hour, adjust the pH to 3~4, and the solid content is 35% .

Embodiment 3

[0069] 1. In a 500ml four-necked flask, add 15g of polyoxypropylene diol, 10g of flame retardant polyol compound, add 7g of xylene diisocyanate (TDI) after vacuum dehydration, and react at 80°C for 3 hours under nitrogen protection. A polyurethane prepolymer was obtained with a -NCO content of 5.2%.

[0070] 2. In a 500ml four-necked flask, add 4g of ethyl acetate, stir for 10 minutes, add 45ml of sodium bisulfite aqueous solution and 55ml of ethanol for emulsification, add hydrochloric acid after 1 hour, adjust the pH to 3~4, and the solid content is 33% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com