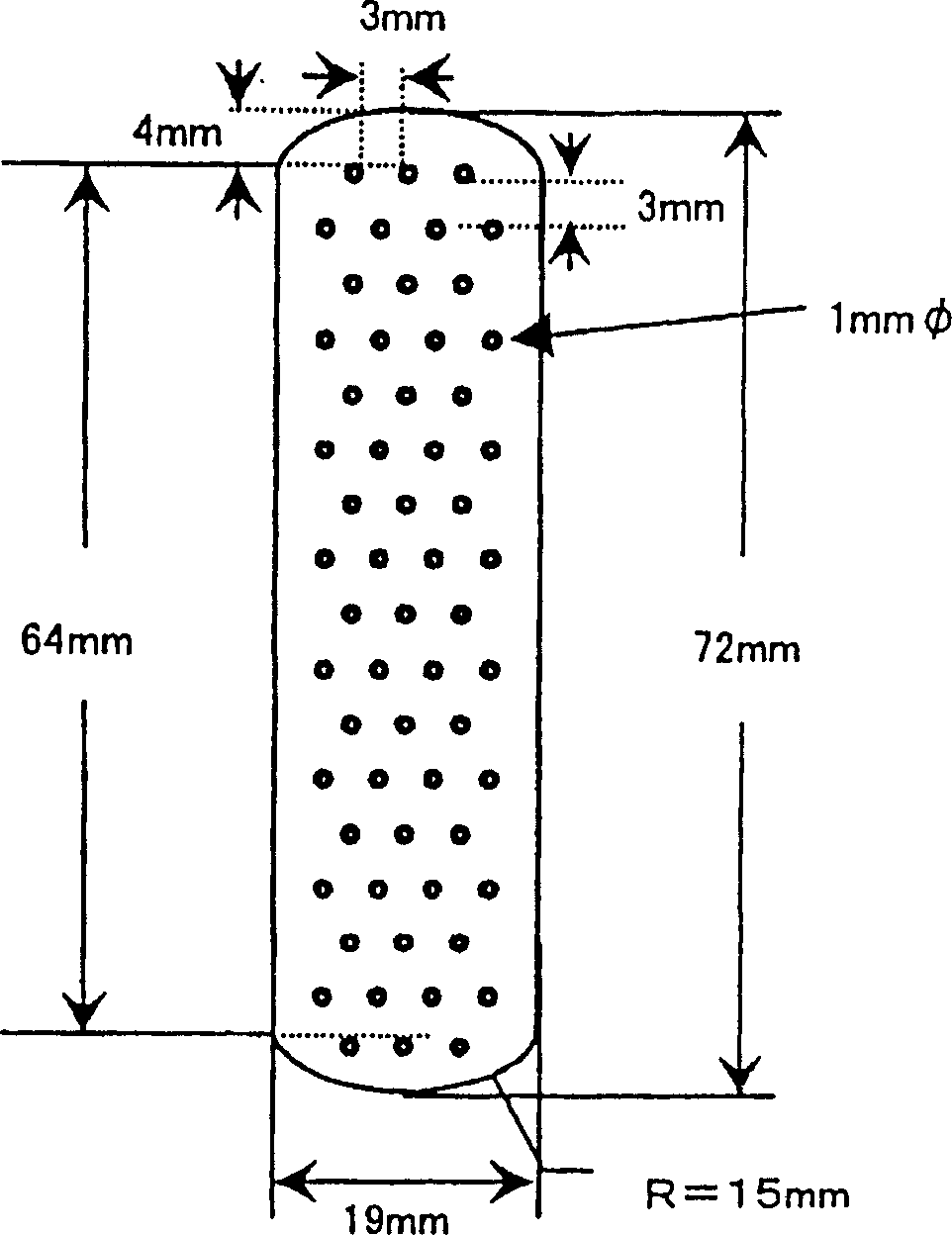

Pressure-sensitive adhesive sheet for application to skin and first-aid plaster

A technology of pressure-sensitive adhesive tape and pressure-sensitive adhesive layer, which is applied in applications, bandages, medical devices, etc., and can solve the problems of pressure-sensitive tape rupture, easy peeling, and insufficient mechanical strength of the substrate film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (Preparation of film by calendering and evaluation of calendering properties)

[0063] The resin composition having the composition shown in Table 1 was formed into a film having a thickness of 100 μm using a two-roll mill with a surface temperature of 170° C. During this process, the resin composition was tested for calendering properties based on peelability and haul-off. That is, in terms of peelability, A indicates the case where the resin composition can be easily released from the roll when the film is peeled off from the roll, and B indicates the case where the resin is difficult to release from the roll. In terms of traction property, A indicates the case where the film can be drawn without any problem when peeled off the roll, and B indicates the case where the film sags or breaks when peeled off the roll.

[0064] (preparation of substrate film and evaluation of anti-adhesion)

[0065] Subsequently, a resin composition having calendering properties (evaluate...

Embodiment 2-8

[0083] The calendering properties of the resin compositions were examined in the same manner as in Example 1, except that each of the resin compositions shown in Table 1 was used. Thereafter, each resin composition was formed into a film having a thickness of 70 μm by calendering. The adhesiveness of the obtained film was examined by the same method as in Example 1. The results are shown in Table 1.

[0084] In the same manner as in Example 1, the film thus obtained was used as a substrate film for preparing a pressure-sensitive adhesive tape. The 10% modulus, wearing feeling, dynamic friction coefficient, surface slipperiness, curl sensitivity and peel strength of the pressure-sensitive adhesive tape thus obtained were examined. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com