IC socket assembly

A technology of sockets and components, which is applied in the field of IC socket components, can solve problems such as discrepancies in flatness of circuit boards, deterioration of electrical connection reliability, and inability to ensure coplanarity, so as to ensure reliability, ensure coplanarity, and reduce warping and deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

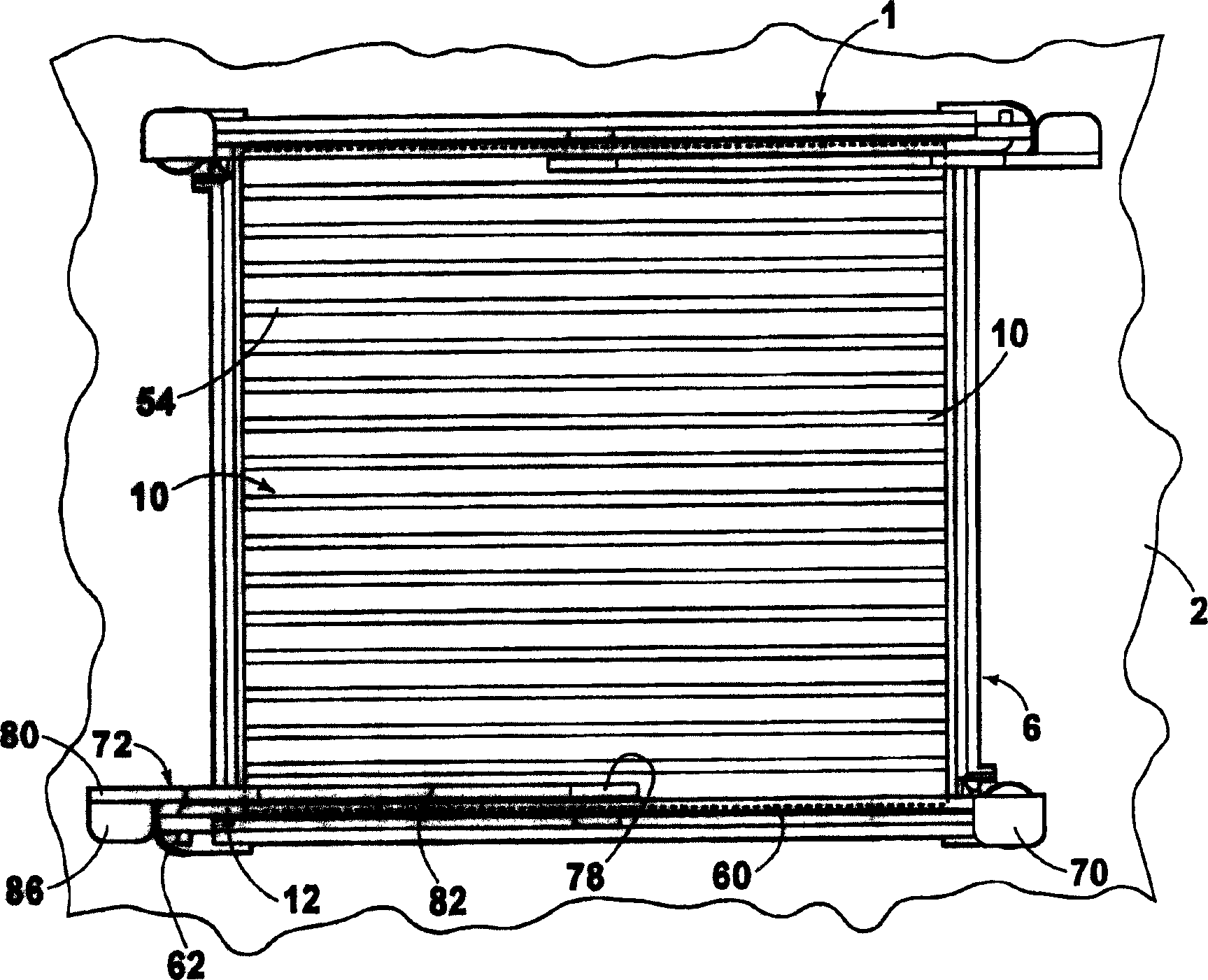

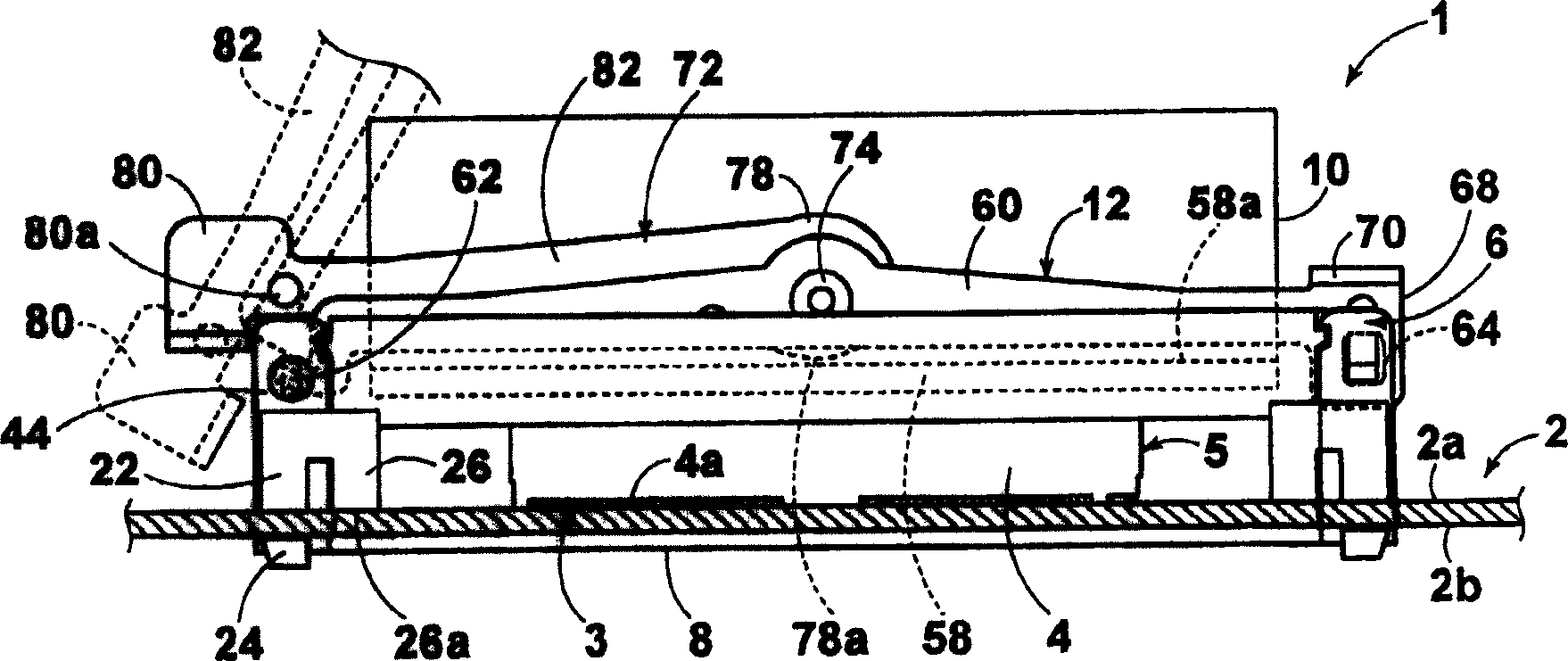

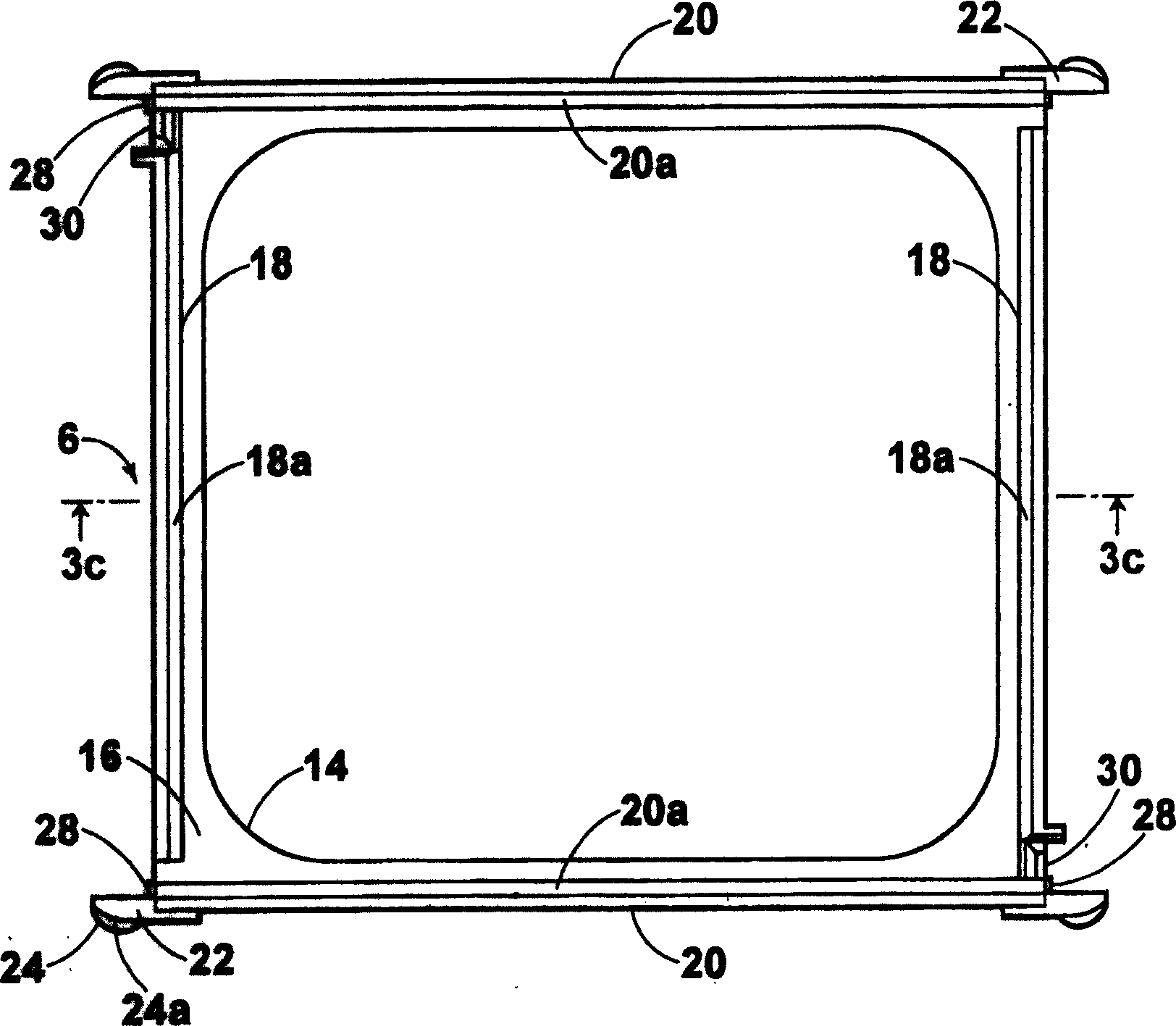

[0042] Hereinafter, preferred embodiments of the IC socket assembly (hereinafter simply referred to as "assembly") according to the present invention will be described with reference to the accompanying drawings. figure 1 is a plan view of an assembly 1 according to the first embodiment, wherein the assembly 1 is mounted on a printed circuit board 2 (hereinafter simply referred to as "circuit board"). figure 2 yes figure 1 A front view of the state of assembly 1 is shown. refer to figure 1 and figure 2 Describe component 1. The assembly 1 includes: a frame 6, which is located on the first surface 2a of the circuit board 2; a rear plate 8, which is mounted on the second surface 2b of the circuit board 2 opposite to the first surface 2a, corresponding to the position of the frame 6; A socket housing 4 (hereinafter simply referred to as "housing") for accommodating the IC socket 5 is provided in the frame 6; a heat sink 10 is mounted to the top of the housing 4; and a load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com