Process for preparing mordenite/ZSM-5 mixed crystal material

A technology of mordenite and ZSM-5, which is applied in the field of preparing mordenite/ZSM-5 mixed crystal materials, and achieves the effect of low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

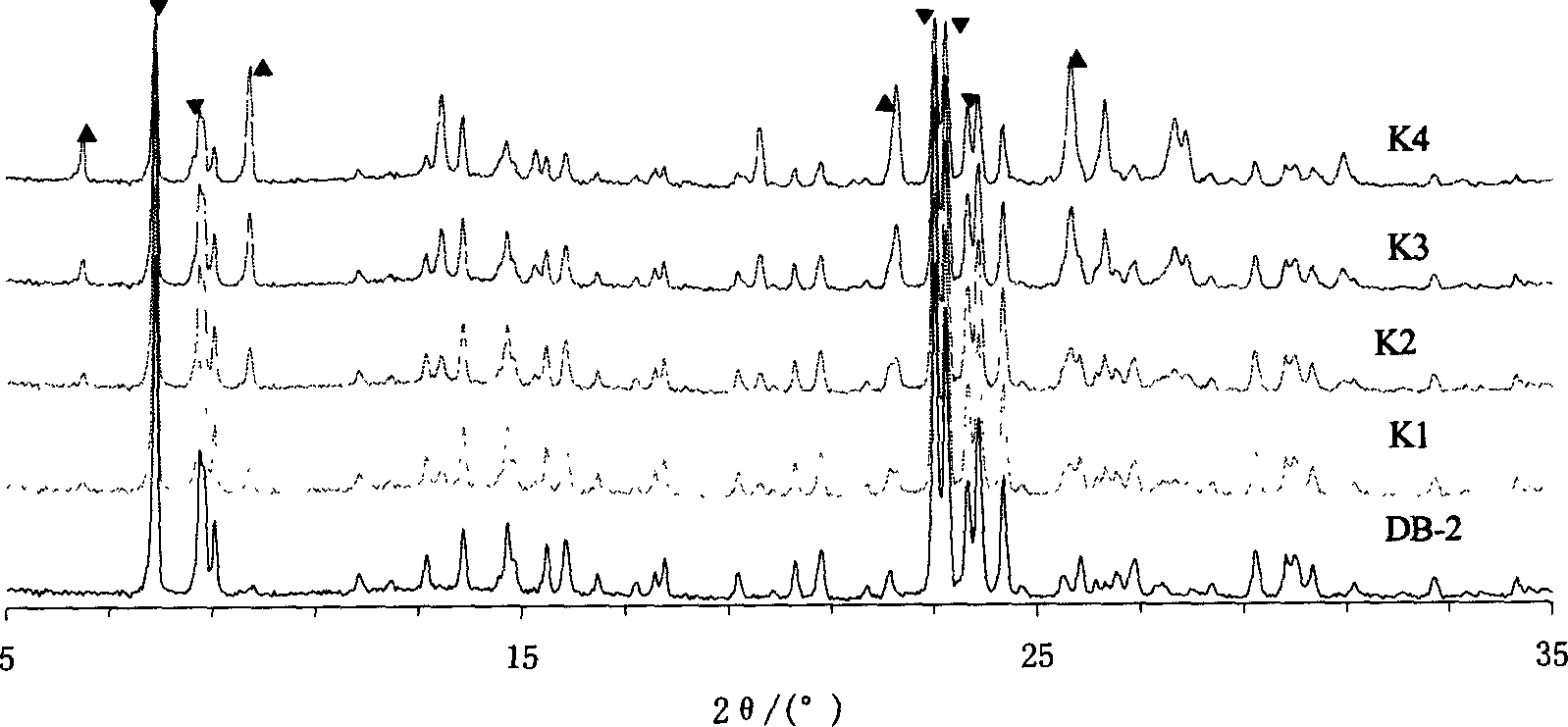

Embodiment 1

[0053] Raw materials: 35.1g aluminum sulfate solution

[0054] 70.7g water glass

[0055] 12.4g sulfuric acid solution

[0056] 98.7g H 2 o

[0057] 0.8g NaZSM-5

[0058] Experimental process: First slowly add aluminum sulfate solution under stirring water glass solution to form a gel, then add sulfuric acid solution, add NaZSM-5 seed crystals during rapid stirring, then stir it vigorously, and add the mercerizing compound synthesized in Comparative Example 1 after stirring well 0.5 g of zeolite seed crystals, then moved into a reaction kettle, crystallized at 165°C for 48 hours, and dried in an oven at 100-110°C for 3-4 hours to obtain the raw powder of the mixed crystal material, coded as K1.

Embodiment 2

[0060] Raw materials: 35.1g aluminum sulfate solution

[0061] 70.7g water glass

[0062] 12.4g sulfuric acid solution

[0063] 98.7g H 2 o

[0064] 0.8g NaZSM-5

[0065] Experimental process: First slowly add aluminum sulfate solution under stirring water glass solution to form a gel, then add sulfuric acid solution, add NaZSM-5 seed crystals during rapid stirring, then stir it vigorously, and add the mercerizing compound synthesized in Comparative Example 1 after stirring well 0.9g of zeolite seed crystals, then moved into the reaction kettle, crystallized at 165°C for 48 hours, and dried in an oven at 100-110°C for 3-4 hours to obtain the raw powder of mixed crystal material, coded as K2.

Embodiment 3

[0067] Raw materials: 35.1g aluminum sulfate solution

[0068] 70.7g water glass

[0069] 12.4g sulfuric acid solution

[0070] 98.7g H 2 o

[0071] 0.8g NaZSM-5

[0072] Experimental process: First slowly add aluminum sulfate solution under stirring water glass solution to form a gel, then add sulfuric acid solution, add NaZSM-5 seed crystals during rapid stirring, then stir it vigorously, and add the mercerizing compound synthesized in Comparative Example 1 after stirring well 1.6 g of zeolite seed crystals were then transferred into a reaction kettle, crystallized at 165°C for 48 hours, and then dried in an oven at 100-110°C for 3-4 hours to obtain the raw powder of the mixed crystal material, coded as K3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com