Prepn. of inner chanber contacting vertical chamber emitting laser by 3-shaft self-aligning process

A vertical cavity surface emission and self-alignment technology, which is applied in the field of VCSEL manufacturing process, can solve the problems of low lithography precision and non-repeatable complete alignment of three axes, so as to increase the number of lithography times and reduce the lithography precision the effect of the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

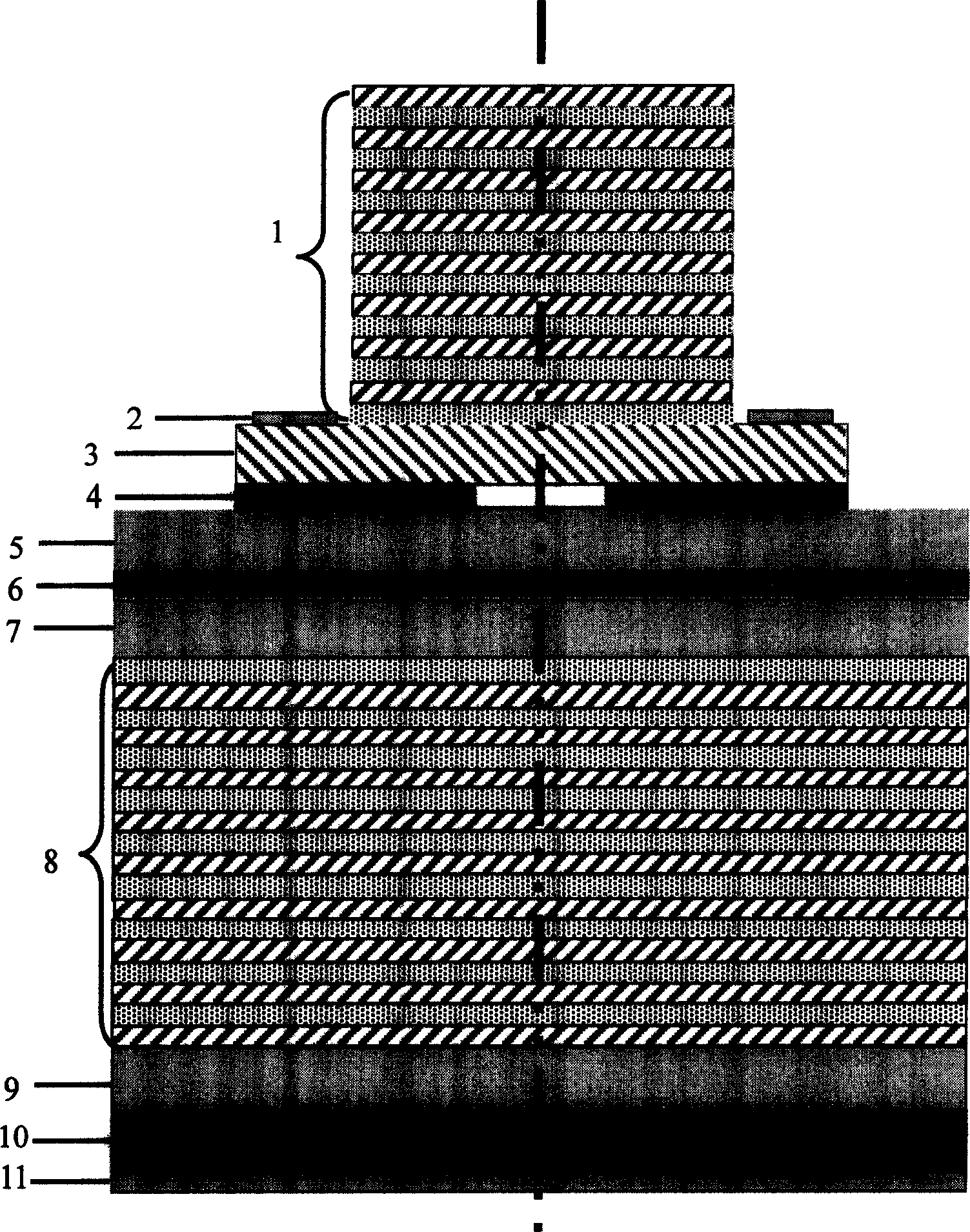

[0040] Such as Figure 3-1 Shown in ~9, its preparation process and method are as follows:

[0041] 1. Using common metal-organic chemical vapor deposition (MOCVD) method in n + -GaAs buffer layer 9, 28 pairs of 70nm GaAs / 80nm Al are epitaxially grown sequentially on GaAs substrate 10 0.9 Ga 0.1 Distributed Bragg Reflector 8 under As, 110nm Al x Ga 1-x As (xx Ga 1-x As(x0.98 Ga 0.02 As wet oxynitride layer 4, 100nm GaAs ohmic contact layer 3, 20 pairs of 70nmGaAs / 80nm Al 0.9 Ga 0.1 Distributed Bragg reflector 1 on As, where GaAs and Al 0.9 Ga 0.1 As are two materials constituting the upper and lower distributed Bragg reflectors respectively.

[0042] 2. Using Karl Suss BJ3 photolithography machine, and positive photoresist PR4200 photoresist, after exposure and development, the surface of the MOCVD growth sample is formed as Figure 3-1 The photoresist pattern shown.

[0043] 3. Using traditional dry etching technology (such as ICP or RIE) or wet chemical etching tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com