Deinking Technique for news bogus paper through enzyme

A technology of newsprint, technology, applied in the field of pulp and paper making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

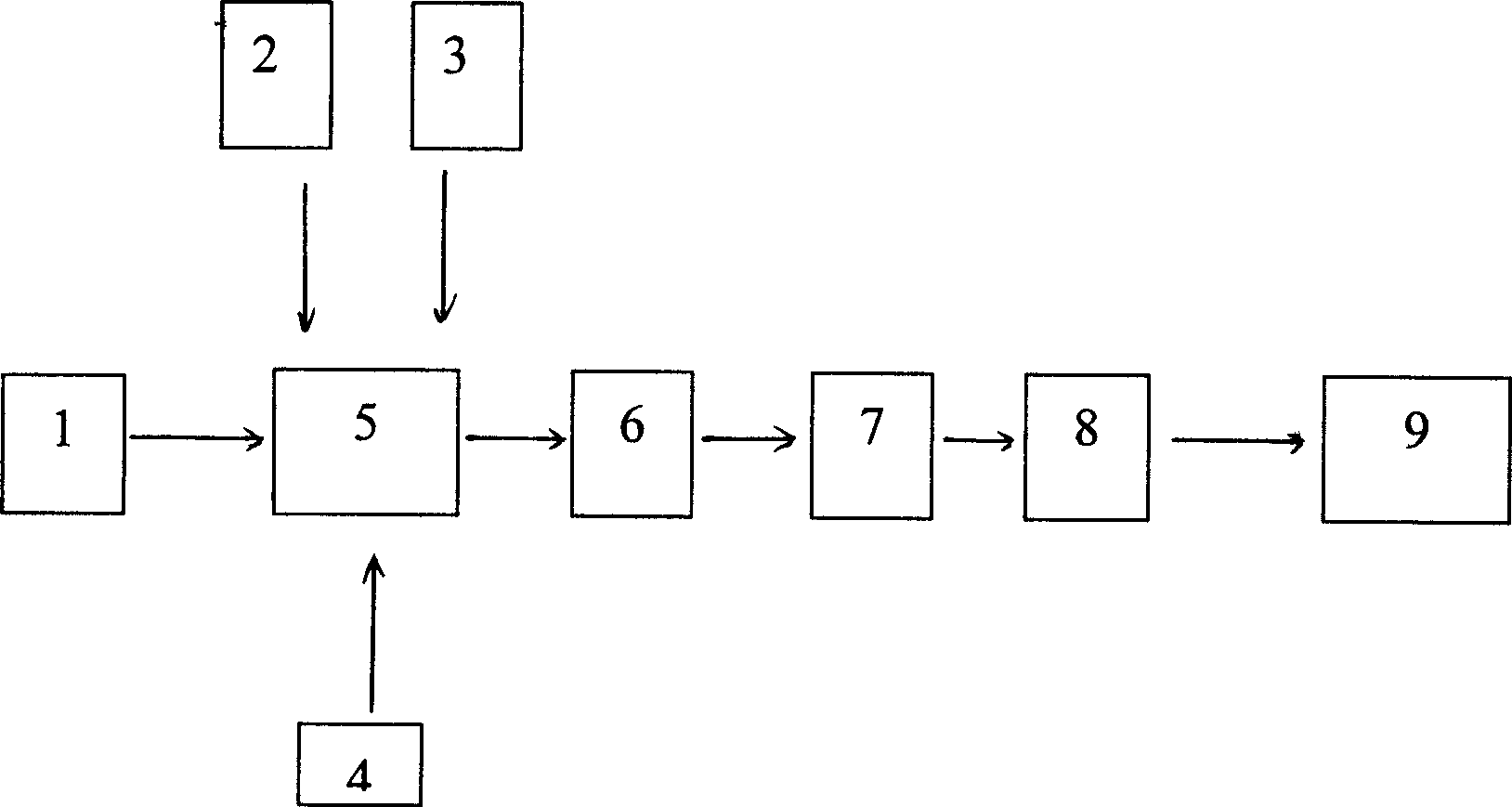

Image

Examples

Embodiment 1

[0015] (1) Pulping: Pulping is carried out in a pulper. 8# American waste is added in the pulper, ventilated oxygen, add 0.2% deinking agent (Tween80 and fatty alcohol polyoxyethylene ether weight ratio 1: 1), 10LAMU / g laccase NS 51003 (Denmark Novozymes company production), 0.5% violuric acid, and oxygen. Control pulp concentration to 10%, temperature at 60°C, pulper rotor rotation frequency at 25Hz, crushing for 15-60min, and heat preservation for 0-30min.

[0016] (2) Flotation: Flotation is carried out in a flotation tank. Dilute the disintegrated pulp with water to a pulp concentration of 1%, add 0.1%-2.0% deinking agent, and control the air flow to 8-25m 3 / h, the pressure is 0.3-1.0MPa, flotation at room temperature for 5-30min.

[0017] (3) Washing: the pulp after flotation is diluted to a pulp concentration of 0.2%-0.5%, and washed and concentrated by an 80-mesh copper mesh.

[0018] (4) Bleaching: The deinked pulp is bleached with hydrogen peroxide. Slurry conce...

Embodiment 2

[0021] (1) Pulping: Pulping is carried out in a pulper. The "Life Daily" published by Dazhong Daily was added to the pulper, and 0.2% deinking agent (Tween80 and fatty alcohol polyoxyethylene ether weight ratio 1: 1), 10LAMU / g laccase NS 51003 (Novi, Denmark) was added to the pulper. Xin company production), 0.5% violin, through oxygen. Control pulp concentration to 10%, temperature at 60°C, pulper rotor rotation frequency at 25Hz, crushing for 15-60min, and heat preservation for 0-30min.

[0022] (2) Flotation: Flotation is carried out in a flotation tank. Dilute the disintegrated pulp with water to a pulp concentration of 1%, add 0.1%-2.0% deinking agent, and control the air flow to 8-25m 3 / h, the pressure is 0.3-1.0MPa, flotation at room temperature for 5-30min.

[0023] (3) Washing: the pulp after flotation is diluted to a pulp concentration of 0.2%-0.5%, and washed and concentrated by an 80-mesh copper mesh.

[0024] (4) Bleaching: The deinked pulp is bleached with h...

Embodiment 3

[0026] Embodiment 3: As described in embodiment 1, the difference is that the deinking agent is Tween80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com