Left ofloxacin and Pidotimod compound preparation tech and its appts.

A preparation process and technology of tea polyphenols, which are applied in the field of preparation process and device of high-purity tea polyphenols and monomeric catechins, can solve the problems of polluting resin columns, complicated process, single separation components, etc., and achieve Save time and equipment, high product yield, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

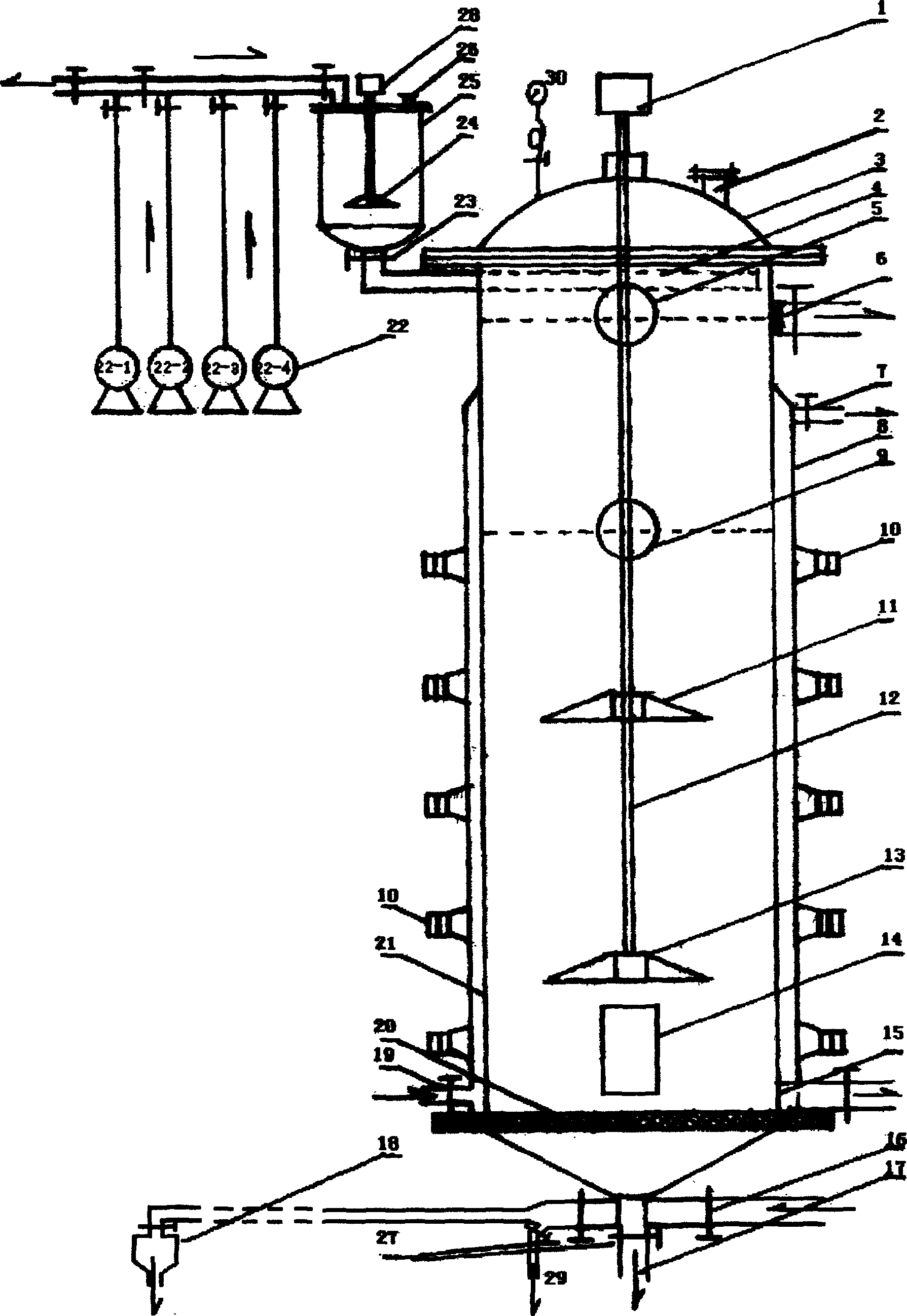

Image

Examples

Embodiment 1

[0031] Embodiment 1 Carry out according to aforementioned extraction process step, sedimentation centrifugation adopts DHC-500 type sedimentation disc separator (the following examples are the same), takes by weighing 150 kilograms of secondary dry green tea leaves, pulverizes to particle size≤1mm, presses tealeaves and pure The weight ratio of water is 1:8~15 (preferably 1:10), the temperature is 90~95°C, add pure water and stir for extraction for 10~20 minutes, and the weight ratio of filtered tea leaves: hot pure water is 1:4 ~6 (preferably 1:5), wash the slag once with hot pure water at 90~95°C, add hydrochloric acid or acetic acid to the tea extract twice to adjust the pH value to 3~4, after sedimentation and separation, the net liquid is adsorbed on the resin column, and the pure After washing the column with water, use ethanol with a weight concentration of 80% to desorb and elute tea polyphenols, control the adsorption flow rate to 8-16 liters / minute (preferably 8 liter...

Embodiment 2

[0033] Example 2 Take 150 kilograms of sub-dried green tea leaves and pulverize them to a particle size of ≤1 mm, add them to an extraction tank at a weight ratio of 1:5 to 8 (preferably 1:7) between tea leaves and 80% ethanol (or methanol), stir and extract for 25 to 10 mm. 35 minutes (preferably 30 minutes), control temperature 60 ~ 65 ℃, extract twice. Press filter to obtain the extract, adjust the pH value to 3-4 with hydrochloric acid (or acetic acid) and then settle and separate. After the liquid and water phases were separated by sedimentation and centrifugation, they were vacuum concentrated to recover ethyl acetate, and the solution phase was sprayed or freeze-dried to obtain a light yellow-white crude product of tea polyphenols. After HPLC analysis, the extraction rate was 13.21% of that of dry tea leaves, and the purity of crude tea polyphenols was ≥73.5%

[0034] Weigh 25 kg of alcohol-extracted crude tea polyphenols, add pure water to dissolve at 1:40 as in Examp...

Embodiment 3

[0035] Example 3 Weigh 25 kg of commercially available crude tea polyphenols, dissolve in pure water at a ratio of 1:50 as in Example 1, and then settle and separate to obtain a net liquid with carbon 18 (C 18 ) resin column adsorption, the control adsorption flow rate is 16 liters / minute, the desorption eluent methanol is added by a gradient of 1% per minute, and the elution gradient interval is 15% to 55%, only one elution is performed, and at the same time in pure water Add 0.05% TFA to the mixture, the desorption flow rate is constant at 9 liters / min, and the peak liquid of each monomer catechin is regularly collected according to the peak collection process in Example 1: EGC liquid is collected between 11 and 13 minutes, and DL is collected between 13.5 and 14.5 minutes -C solution, collect EGCG solution between 15 and 19 minutes, collect EC solution between 19.5 and 21 minutes, collect CAF solution between 21.5 and 25 minutes, collect GCG solution between 26 and 28 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com