Processing unit for reclaiming dirty oil from united station in oil field

A technology of sewage oil recovery and treatment device, which is applied in the fields of grease/oily substance/float removal device, centrifugal separation water/sewage treatment, liquid separation, etc. , environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

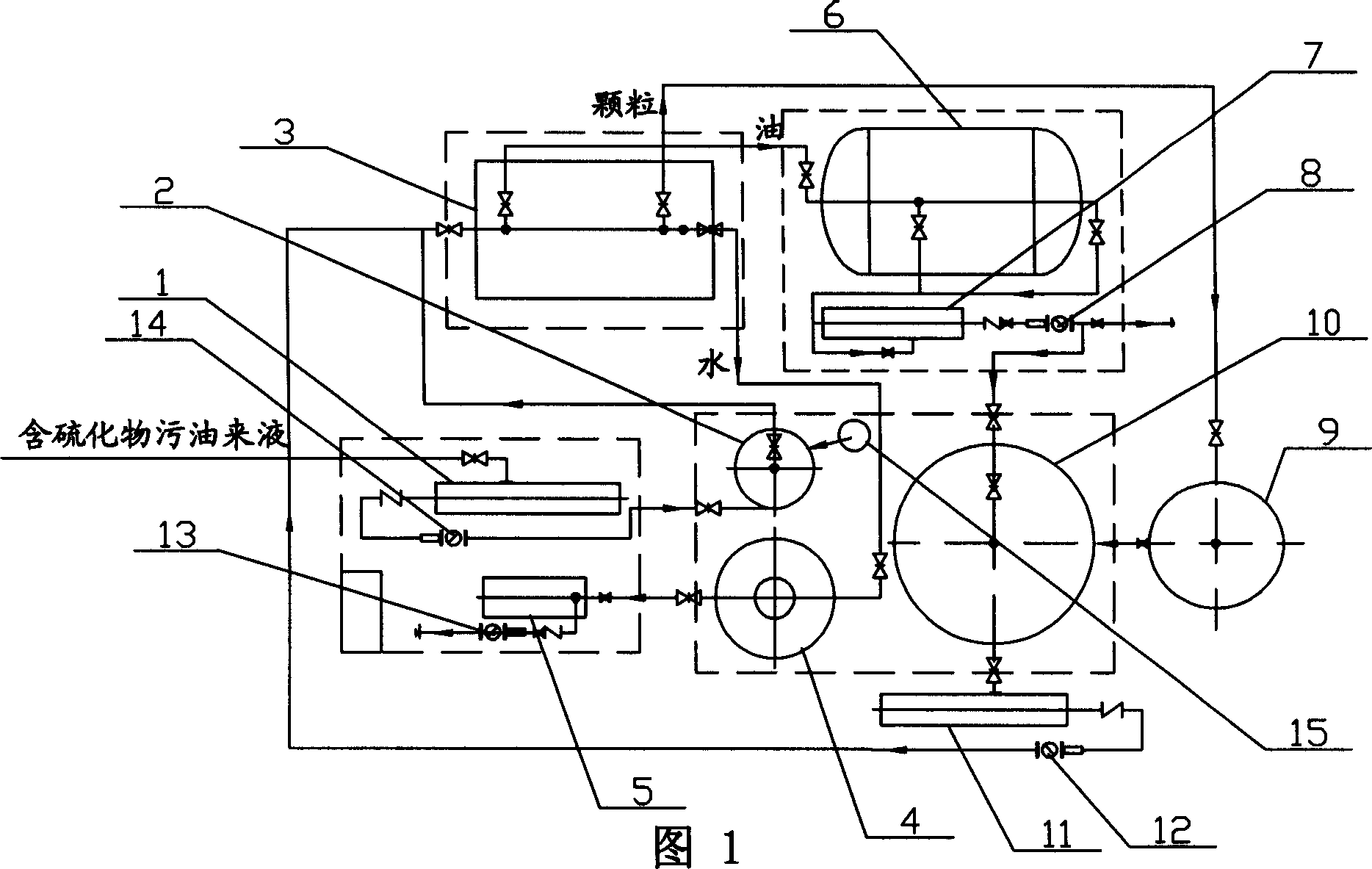

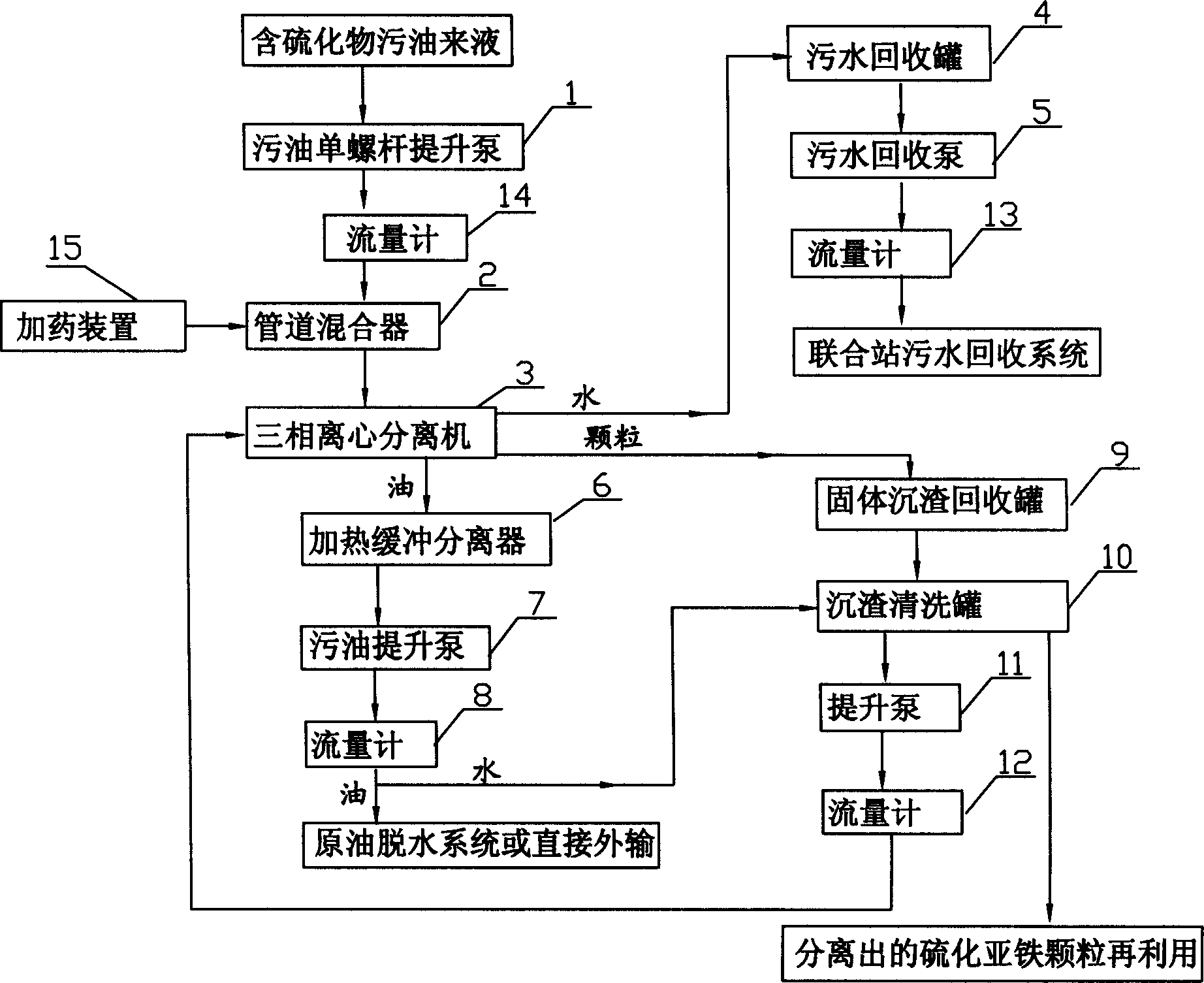

[0005] Specific embodiment 1: This embodiment includes sewage oil single-screw lifting pump 1, pipeline mixer 2, three-phase centrifugal separator 3, sewage recovery tank 4, sewage recovery pump 5, heating buffer separator 6, sewage oil lifting pump 7 , solid sediment recovery tank 9, sediment cleaning tank 10 and lift pump 11, their connection mode is: one end of pipeline mixer 2 is connected with one end of single screw lift pump 1, and the other end of pipeline mixer 2 is connected with centrifugal separator 3 The inlet of the centrifuge 3 is connected to each other; the sewage outlet of the centrifuge 3 is connected to one end of the sewage recovery tank 4, the other end of the sewage recovery tank 4 is connected to one end of the sewage recovery pump 5, and the other end of the sewage recovery pump 5 is connected to the sewage treatment system; centrifugal separation The separation slag outlet of machine 3 links to each other with one end of solid sediment recovery tank 9,...

specific Embodiment approach 2

[0006] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a flow meter 13 is installed between the sewage recovery pump 5 and the sewage treatment system, and a flow meter is installed between the lift pump 11 and the centrifuge 3 12. A flow meter 8 is installed between the waste oil lifting pump 7 and the crude oil dehydration system, and a flow meter 14 is installed between the lifting pump 1 and the pipeline mixer 2.

[0007] The working principle of the present invention is: the dirty oil produced in the treatment facilities in the oil field combined station production liquid treatment system enters the pipeline mixer 2 after passing through the dirty oil single-screw lifting pump 1 and the flow meter 14, and can pass through the dosing device 15 in the pipeline mixer. The sewage oil purifier is added into the pipeline mixer 2, and after being mixed by the pipeline mixer 2, it enters the three-phase centrifuge 3 to separate oil, water and black co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com