Glycerine monoester laurate micro emulsion and its preparing method and use

A technology of monolaurin monoglyceride and microemulsion, which is applied in the fields of application, food science, food preservation, etc., can solve the problems of insufficient dissolution or dispersion, difficult antiseptic effect, etc., and achieves extended shelf life, simple preparation method, The effect of high thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weighing by weight percentage: 24% polyoxyethylene sorbitan monolaurate, 12% polyoxyethylene sorbitan monooleate, 8% lauric monoglyceride, 16% n-amyl alcohol, 9% lauryl Alcohol and 31% water, first mix polyoxyethylene sorbitan monolaurate, polyoxyethylene sorbitan monooleate, lauric monoglyceride, n-amyl alcohol and lauryl alcohol at a temperature of 40 ° C, and wait for this After the mixture is completely melted, slowly add water and stir while adding until the mixed liquid turns from cloudy to clear.

Embodiment 2

[0027] Take by weight percentage: 35% polyoxyethylene sorbitan monolaurate, 10% lauric monoglyceride, 10% n-amyl alcohol, 15% lauryl alcohol and a concentration of 20% potassium sorbate solution 30%, Stir and mix polyoxyethylene sorbitan monolaurate, lauric monoglyceride, n-pentyl alcohol and lauryl alcohol at 40°C. After the mixture is completely melted, slowly add potassium sorbate solution while adding Stir while stirring until the mixture turns from cloudy to clear.

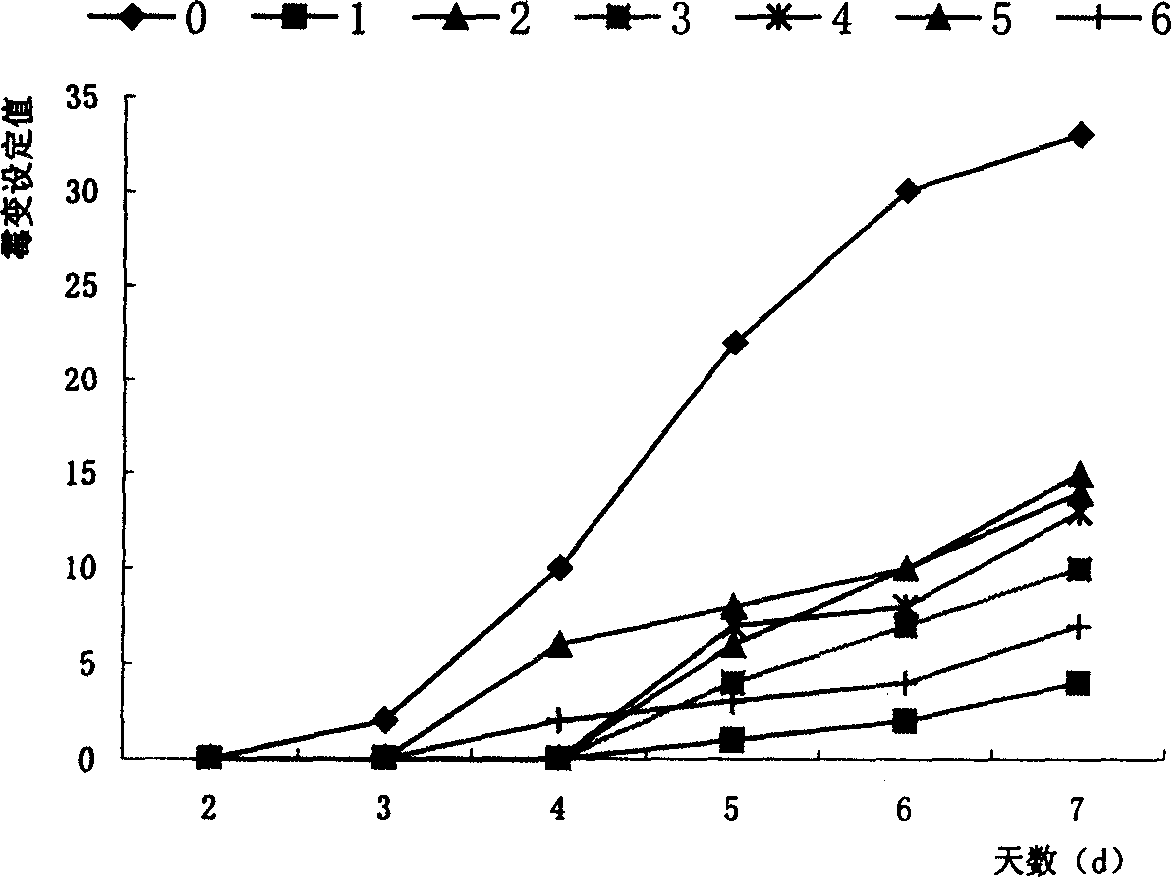

[0028] Add 0.1% product of the present invention by weight in glutinous rice cake dough, make glutinous rice cake dough according to conventional production method. After the production is completed, store the glutinous rice cake dough in a constant temperature incubator with saturated humidity at 30°C, and record the mildew condition on the 2nd, 3rd, 4th, 5th, 6th and 7th day, and measure it with a ruler The diameter of mold spots on the surface of cake dough. The mildew degree of cake dough is expressed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com