Technology of extracting oil and hydrolyzed protein from peanut using hydroenzyme method

A technology for hydrolyzing protein and extracting oil, which is applied in protein food processing, protein composition of vegetable seeds, protein food ingredients, etc., can solve the problems of lack of peanut protein properties, research on recovery methods, no explanation of oil recovery and recovery, and no indications, etc. , to achieve the effects of easy industrial production, improved recovery rate, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

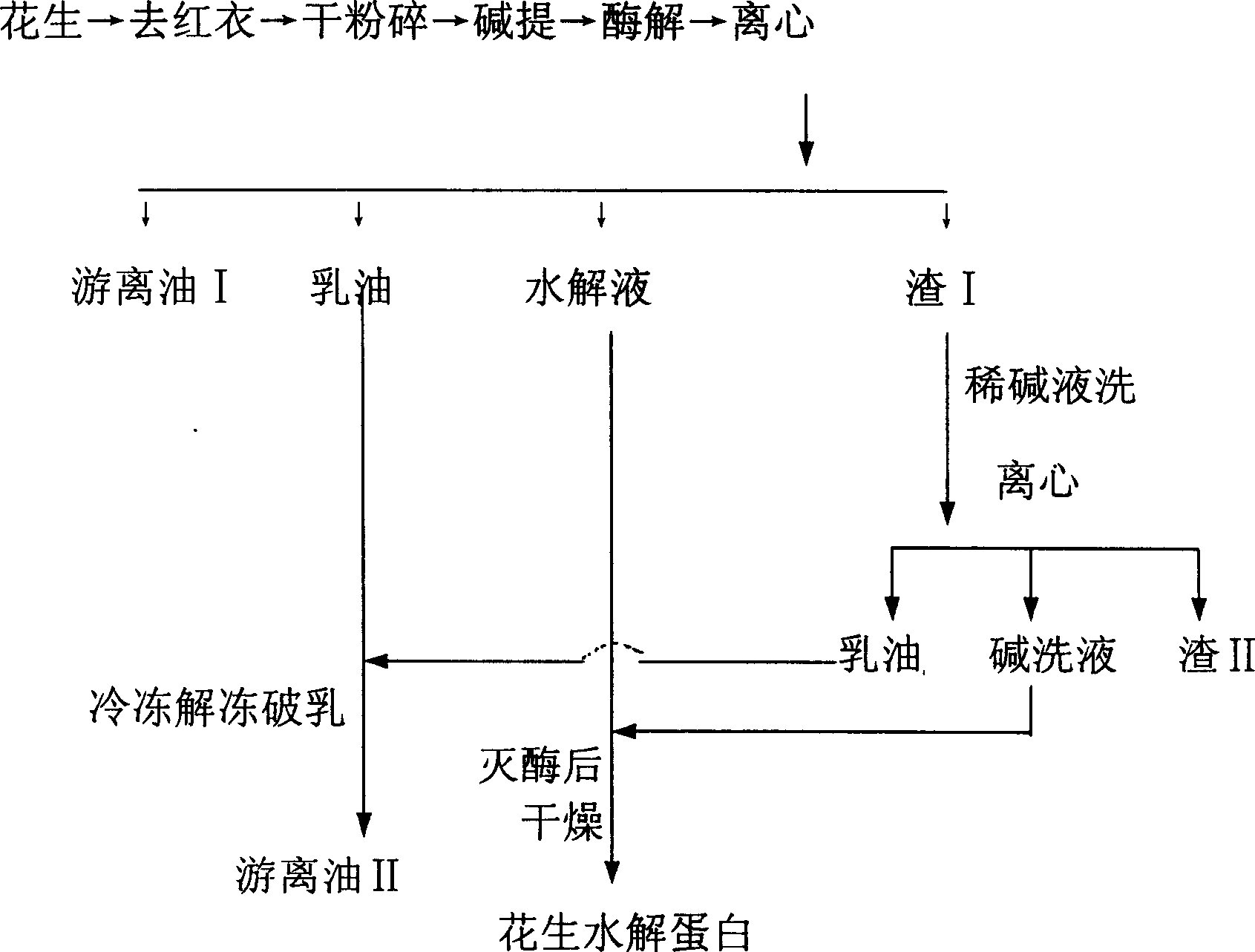

Method used

Image

Examples

Embodiment 1

[0042] The raw material is stripped of the red coat, and the peeled peanut kernels are dry crushed with a portable traditional Chinese medicine grinder. The crushed peanuts are extracted with 4 times the lye, the initial pH of the extraction is 8.25, and the temperature is 60°C. After 20 minutes, the pH of the system was adjusted to 8.00 (within the optimum pH range of Alcalase2.4L), the amount of enzyme added was 2.5ml / 100g protein, and the pH of the system was controlled at about 8.00 by pH-stat. After 7 hours, the degree of hydrolysis of the system was Reached 22.7%.

[0043] The total oil yield was 97.3%, and the total protein yield was 95.6%.

[0044] The total free oil yield was 92.4%, and the recovery rate of peanut hydrolyzed protein reached 90%.

Embodiment 2

[0046] The raw material is stripped of the red coat, and the peeled peanut kernels are dry crushed with a portable traditional Chinese medicine grinder. The crushed peanuts are extracted with 5 times the alkali solution, the initial pH of the extraction is 8.50, and the temperature is 60°C. After 40 minutes, the pH of the system was adjusted to 8.50, the amount of enzyme added was 1.5mL / 100g protein, and the natural enzymatic hydrolysis was carried out for 8 hours.

[0047] The total oil yield was 97%, and the total protein yield was 94.1%.

[0048] The total free oil yield was 91.6%, and the recovery rate of peanut hydrolyzed protein reached 84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com