High speed photoelectric phase control array two dimension laser beam scanner

A two-dimensional laser and beam scanning technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of limited deflection range, large voltage change, and limited scanning accuracy, and achieve stable and reliable integration, no mechanical movement, and scanning fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

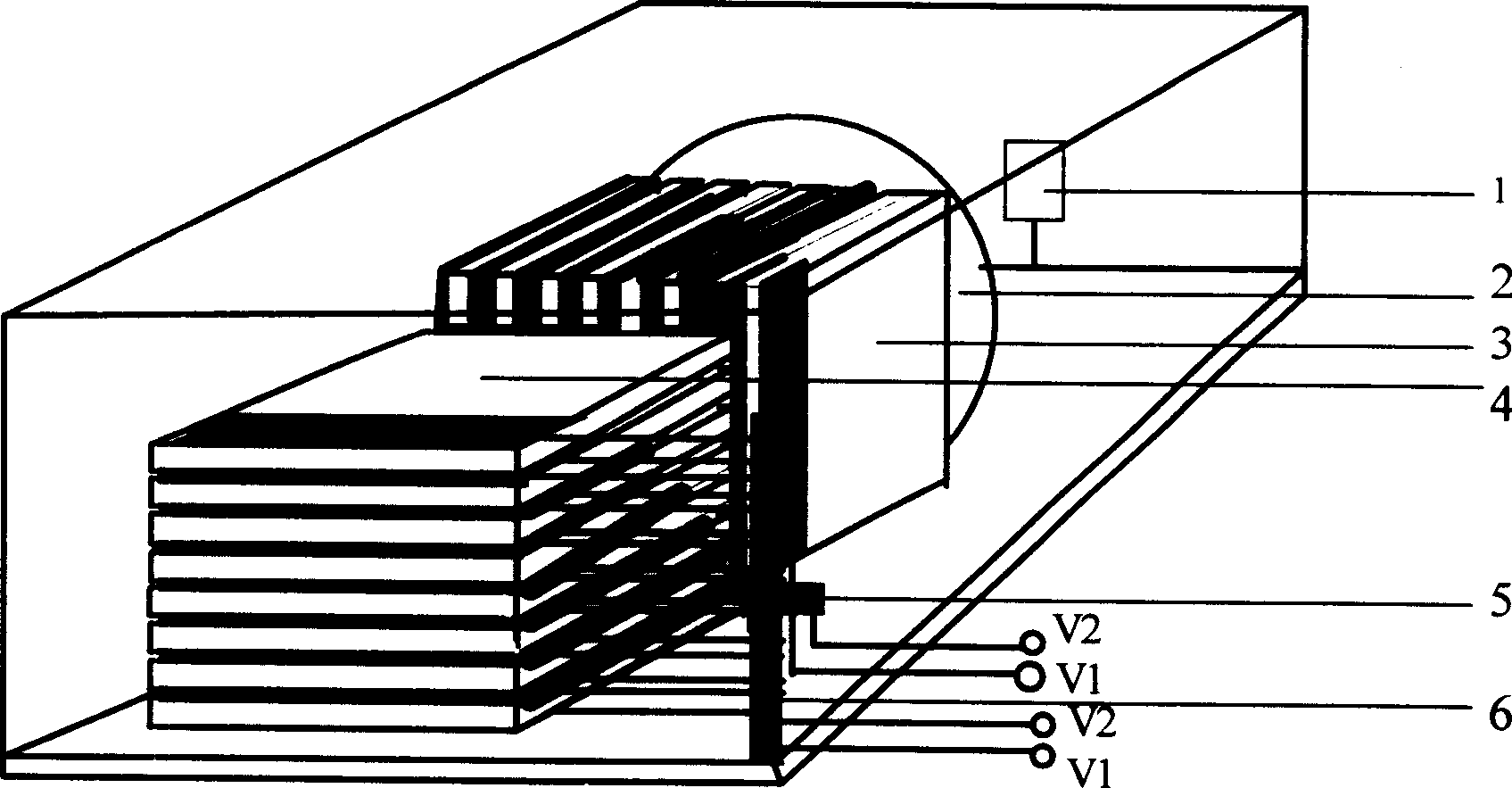

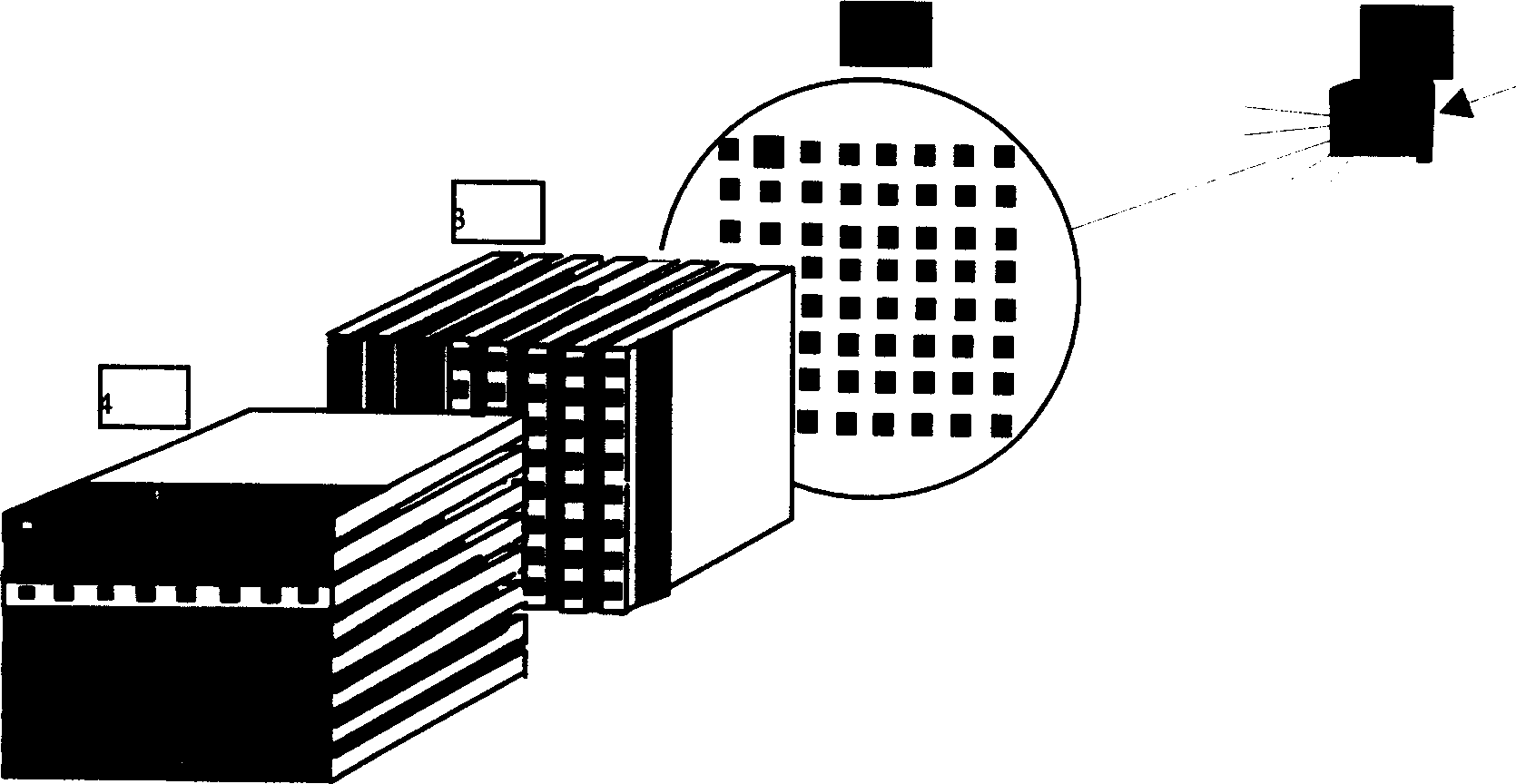

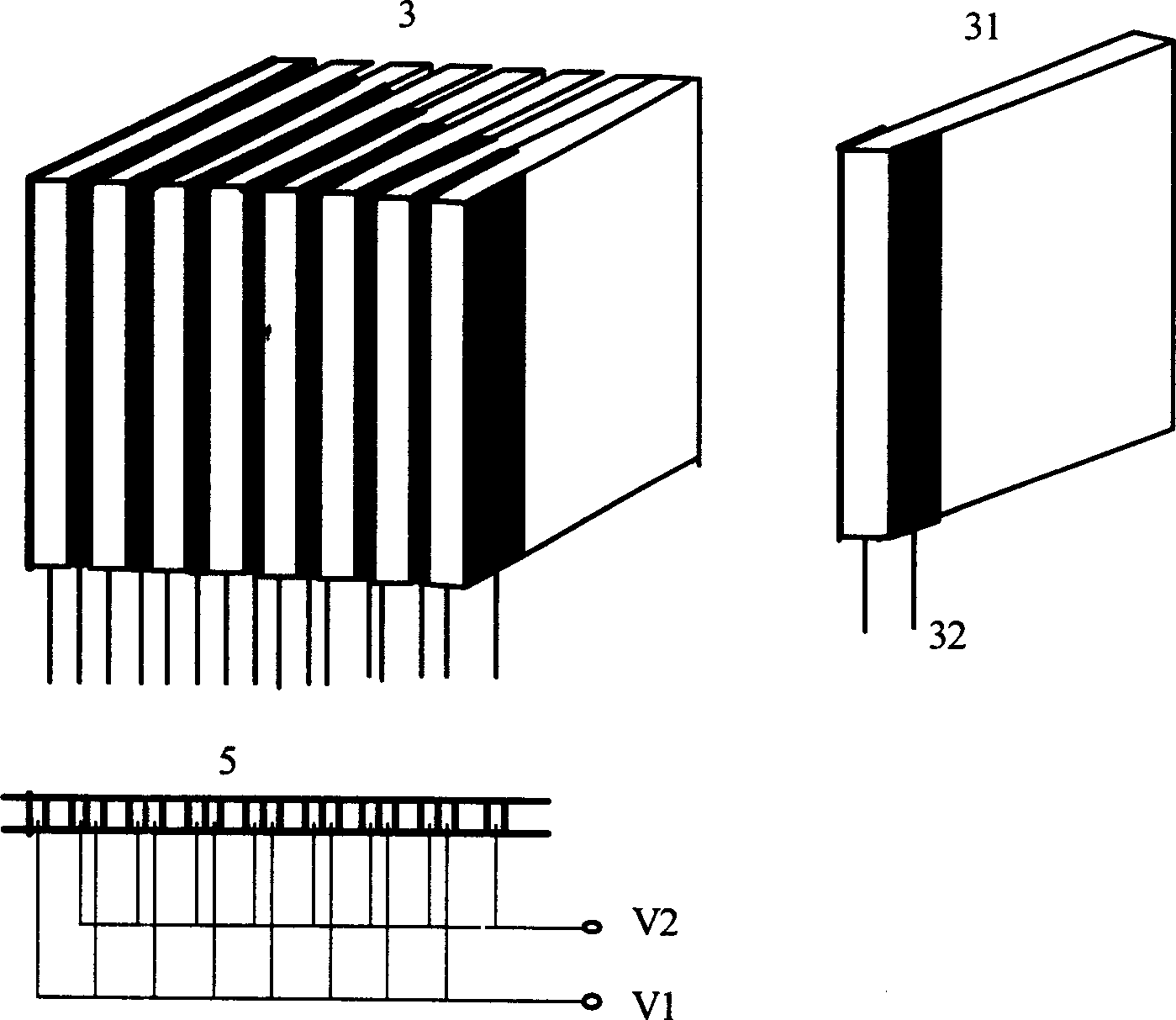

[0030] see first figure 1 , figure 1 It is the basic structure diagram of the present invention, and it can be seen from the figure that the composition of the high-speed electro-optic phased array two-dimensional laser beam scanner of the present invention is: along the direction of beam advancement, it includes in sequence; a plane diffraction grating 1, a collimating lens 2, and a horizontal scanning assembly 3 , the vertical scanning assembly 4, and the electrode socket 5 for inserting the horizontal scanning assembly 3 and the electrode socket 6 for inserting the vertical scanning assembly 4; the plane diffraction grating 1 is located on the focal plane of the collimating lens 2; The horizontal scanning assembly 3 described above is a crystal plate array composed of a plurality of lithium niobate crystal plates 31 with the same structure cut along the optical axis direction, and each lithium niobate crystal plate 31 is sequentially provided with short To the long electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com