Preparing method for cubic silver nanometer grain

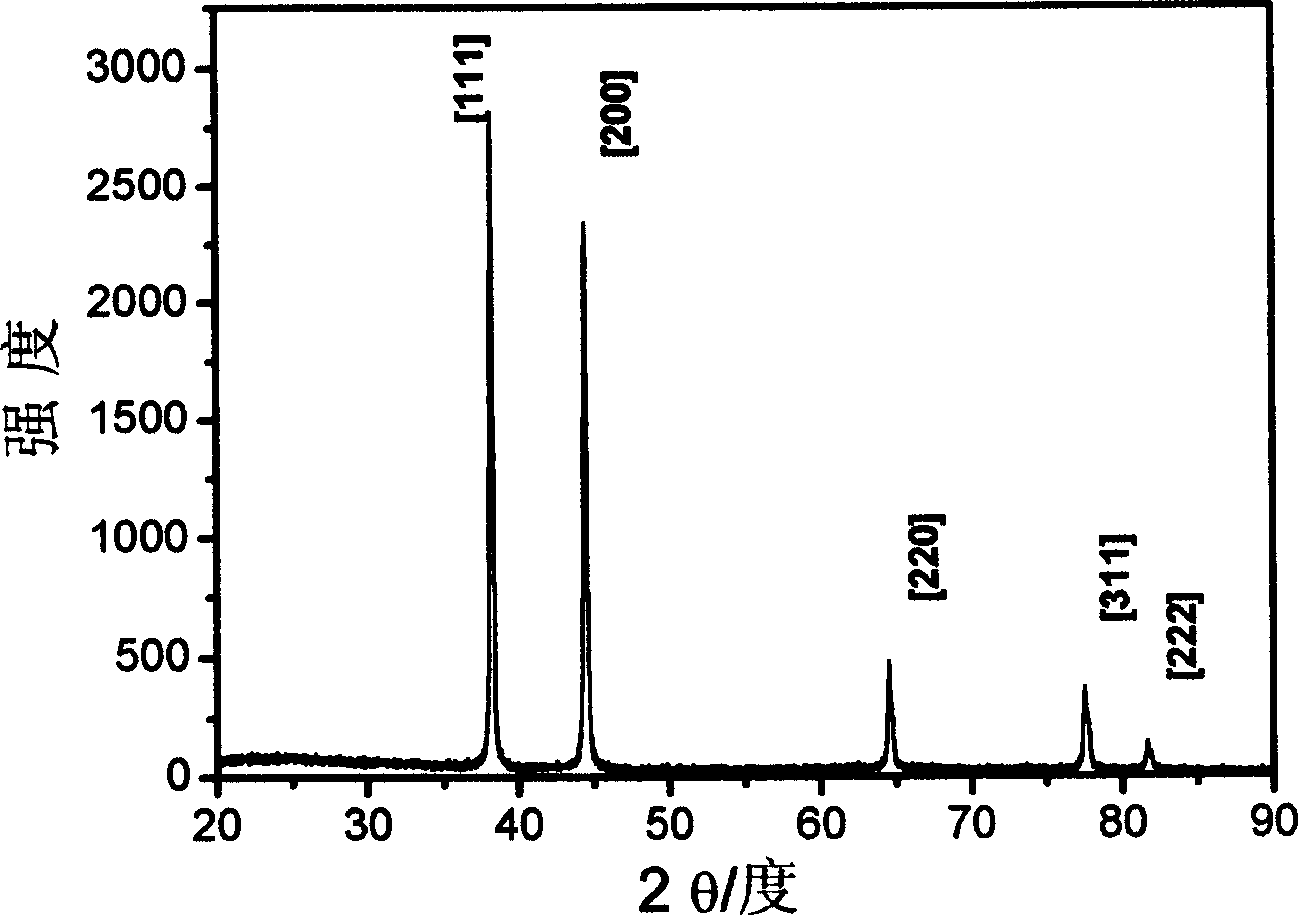

A technology of nanocrystals and silver nanoclusters, which is applied in the field of preparation of cubic silver nanocrystal particles, to achieve the effects of high degree of particle crystallization, good controllability of particle size, and good self-assembly performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

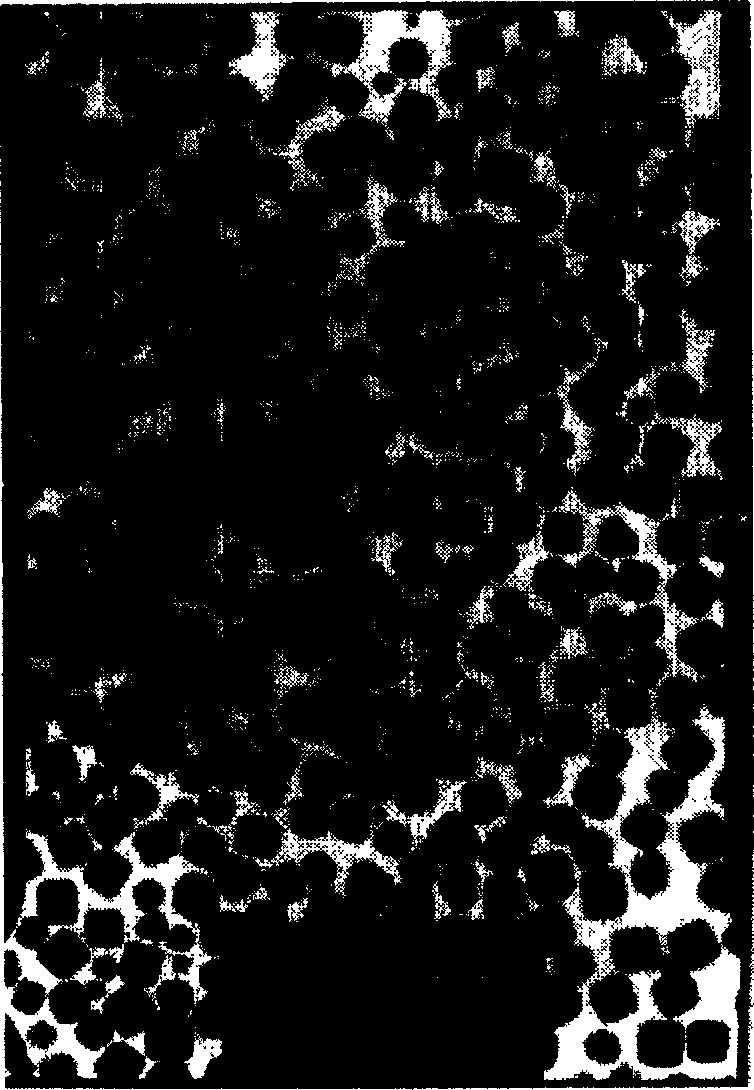

Image

Examples

Embodiment 1

[0037] The tensio-active agent polyvinylpyrrolidone (PVP, molecular weight is 58000) that gets parts by weight is dissolved in the organic solvent ethylene glycol of 27.5 parts by weight; 27.5 parts of organic solvent ethylene glycol; after refluxing 44.2 parts of organic solvent at 160±5°C for 5 minutes, under magnetic stirring, the above two prepared solutions were fed differently from the reactor slowly into the reactor. After the addition was complete, the reaction was allowed to continue for 2 hours. Then, the system was allowed to cool down slowly to room temperature. A yellow-green cubic nano-silver sol was obtained, and particles with an average particle diameter of 50 nanometers were obtained.

Embodiment 2

[0039] The cubic silver nano sol prepared in Example 1 was evaporated at 155°C with a rotary evaporator to remove the organic solvent. Then adding ethanol or water to centrifuge and wash for several times to obtain solid powder of cubic silver nanocrystal particles. During the post-treatment process, there is no change in particle size and shape.

Embodiment 3

[0041] The silver nanocrystalline particle that the solid powder weight part that embodiment 2 obtains is that 1 part is redispersed in the ethanol solvent that the weight part is 99 parts, gets a small amount of sol and drips on the glass plate, spins film with spin coating instrument, can A bright, uniform conductive film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com