Method for extraction and purification of plasmid DNA and its preparation process

A plasmid and production method technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of difficult to master the cracking process, difficult to remove pollution, affect efficiency, etc., to achieve easy implementation and production scale-up, overcome Insufficient cracking, the effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

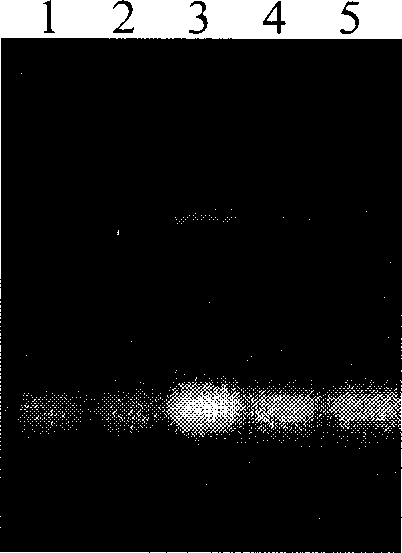

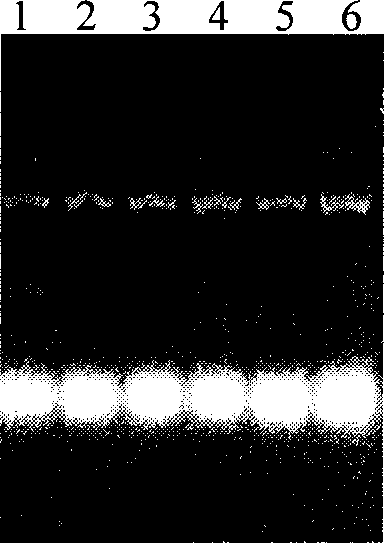

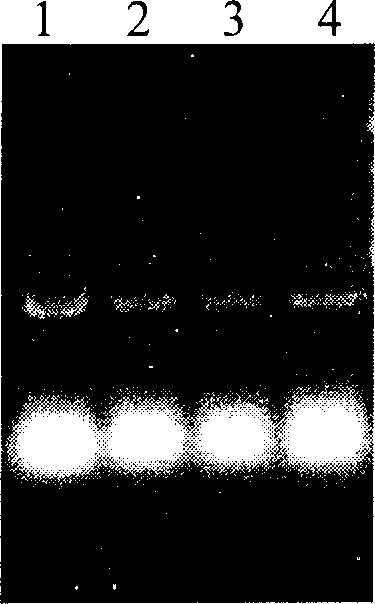

Image

Examples

Embodiment 1

[0043] Embodiment 1: the fermentation of engineering bacterium

[0044] The plasmid pc3d-N was transformed into XL1-blue competent cells, and a single colony was picked from the AMP agar plate and cultured in 5 ml LB (with appropriate amount of antibiotics) at 37°C until the logarithmic growth phase. Take 1.5 ml of the culture and culture it overnight at 37° C. in 150 ml of LB (plus appropriate amount of antibiotics). Add 150 milliliters of the overnight culture to a fermenter filled with 3 liters of LB medium (plus appropriate amount of antibiotics) for fermentation at 37° C. After fermenting for 5 to 6 hours, feed 400 milliliters. OD after 15h of fermentation 600 When there is no longer a significant increase, stop the fermentation and measure the OD 600 for 45.

Embodiment 2

[0045] Embodiment 2: Thalline collection

[0046] 3.5 L of the fermentation broth was pumped into a hollow fiber membrane column with a peristaltic pump for concentration, and after concentration, the cells were washed with 200 ml of TE (10 mM Tris-HCL, 50 mM EDTA, pH=8.0). After concentration, an equal volume of TE was added to the concentrate to continue concentration, and 3.5 L of fermentation broth was finally concentrated to obtain 350 ml of concentrate.

Embodiment 3

[0047] Embodiment 3: Thalline collection

[0048] 15 L of the fermentation broth was pumped into a hollow fiber membrane column with a peristaltic pump for concentration, and after concentration, the cells were washed with 500 ml of TE (10 mM Tris-HCL, 50 mM EDTA, pH=8.0). After concentration, an equal volume of TE was added to the concentrated solution to continue concentration, and 15 L of fermentation broth was finally concentrated to obtain 750 ml of concentrated solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com