Loader integral abrasion proof shovel edge material, heat treatment and welding process

A welding process and integral technology, applied in earth movers/shovels, construction, etc., can solve the problems that the service life of the shovel blade cannot be greatly improved, easy deformation and fracture, poor wear resistance, etc., and achieve obvious economic benefits and Social benefits, uniform water spraying, and simplified process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

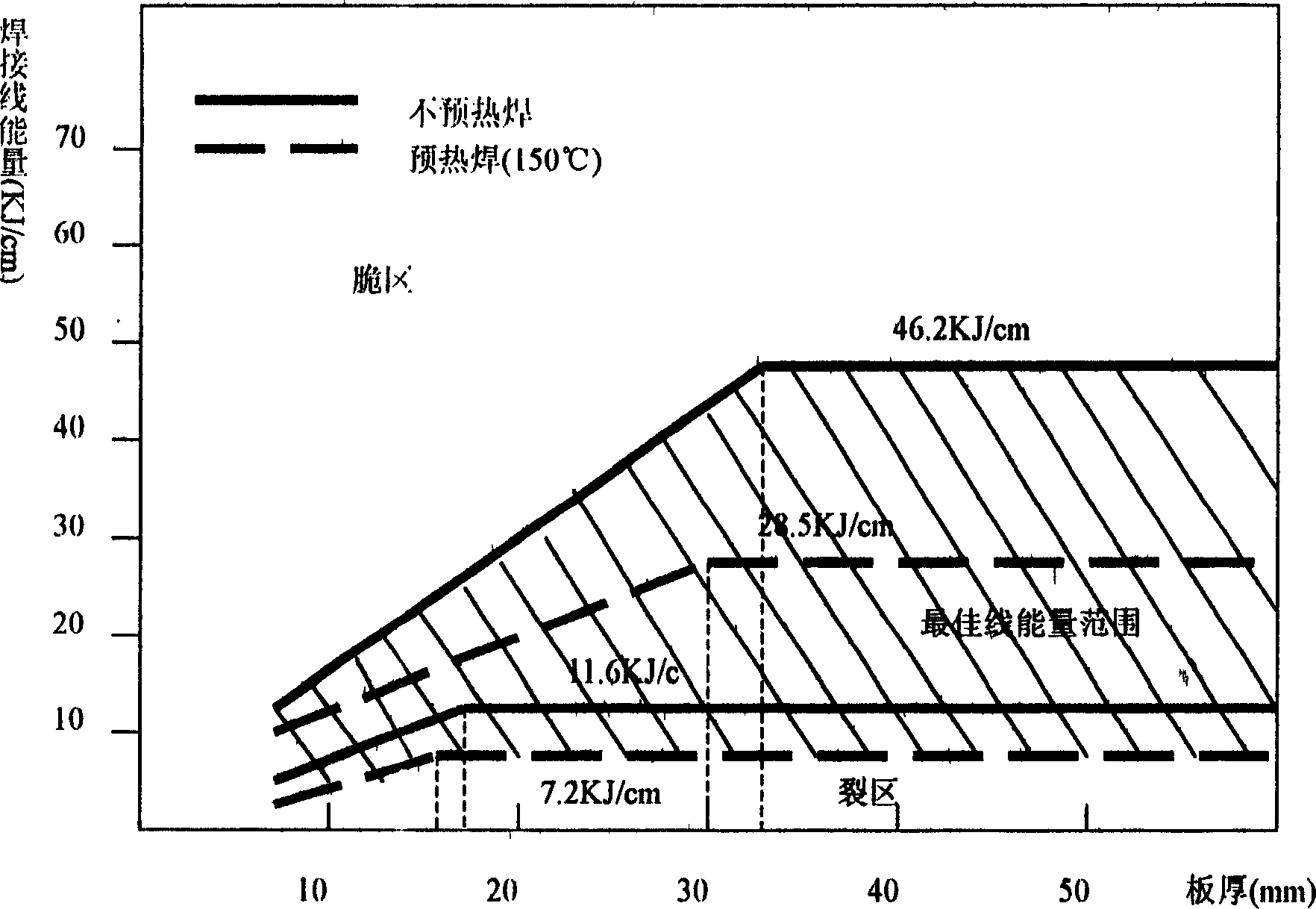

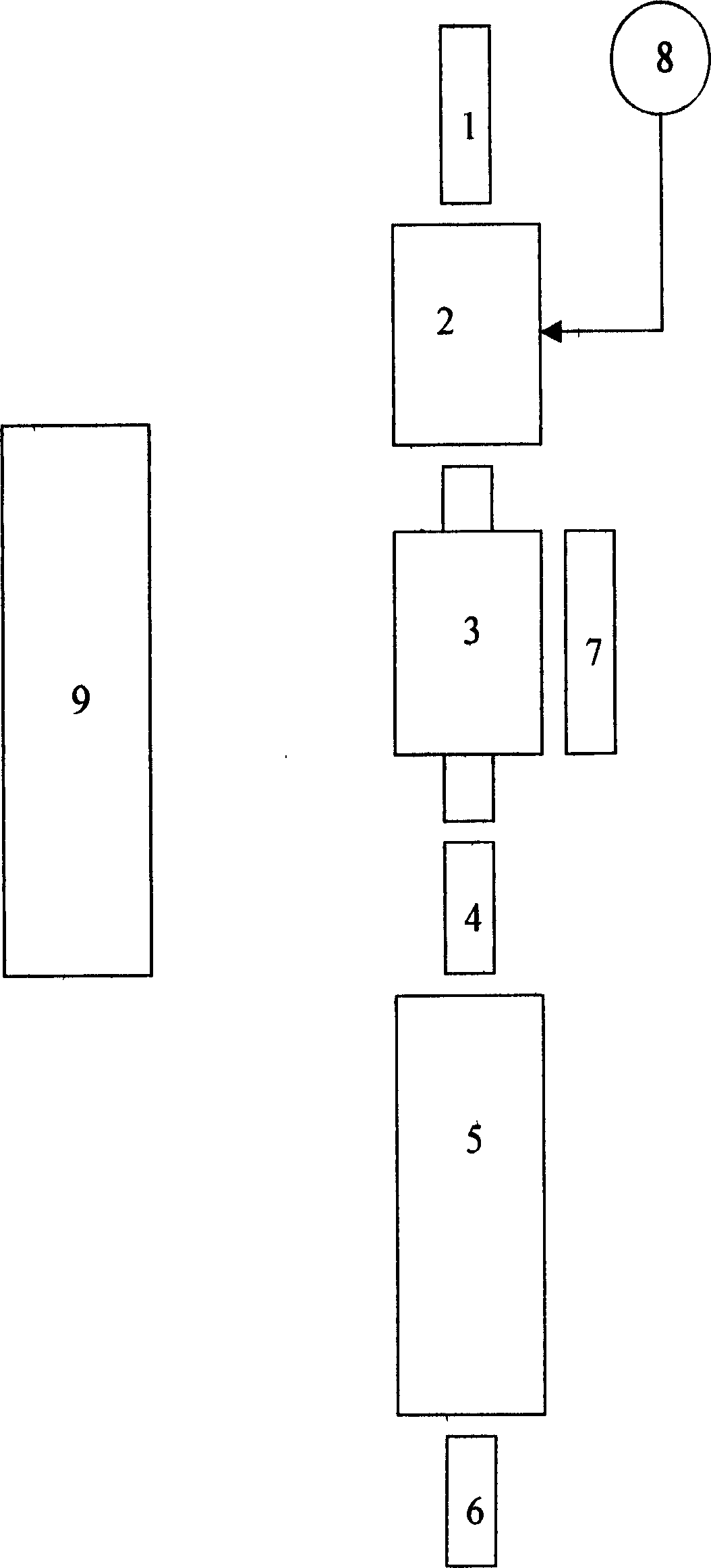

[0012] specific implementation plan

[0013] The invention develops the domestic steel 1E921, which has the characteristics of high strength, good toughness, not easy to deform and break, wear-resistant and good weldability. In order to make it have the above characteristics, a self-made heat treatment production line is characterized by: meeting the heat treatment requirements of the spatula blade, and the heat treatment process is controlled and guaranteed by the equipment; a set of welding methods, welding materials and corresponding welding materials for 1E921 steel and bucket material QJ63 steel Welding process measures to meet the quality requirements for the welding of blades and buckets.

[0014] Embodiments of the present invention are described in detail below.

[0015] 1. Composition of steel 1E921 for shovel blade

[0016]

C

mn

Si

Cr

P

S

Mo

B

0.15

~

0.21

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com