Application of trichloroisocyanuric acid as novel beneficiation inhibitor

A technology of trichloroisocyanuric acid and inhibitor, applied in flotation, solid separation, etc., can solve the problems of unsatisfactory effect and serious mutual inclusion of products in the tank, and achieve improved gold recovery rate, good selectivity, and simplified process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

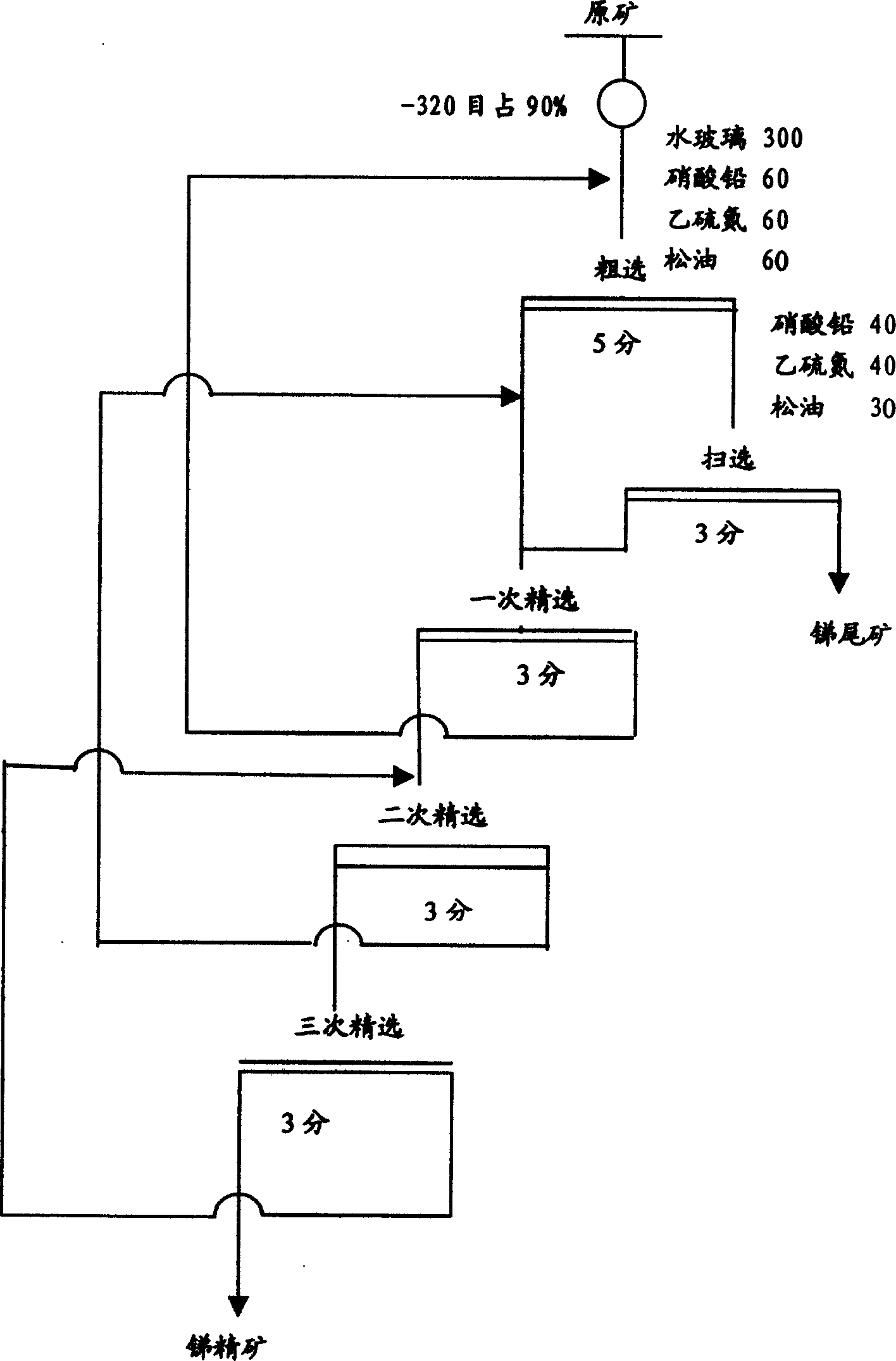

[0013] Without adding any chemicals, the antimony-gold mixed concentrate was naturally selected for separation test. The process is detailed in figure 1 . Put 500g of ore containing 4.8g / t gold and 0.52% antimony into the laboratory-type ore grinding machine, the size of the grinding machine is Φ200×240mm, the grinding concentration is 60%, the grinding time is 8 minutes, and the grinding fineness reaches - 43μm (-320 mesh) accounts for 90%, and the finely ground pulp is used in a laboratory-type flotation machine with a specification of 1.5 liters, and water glass 300g / t, lead nitrate 60+40g / t, ethylsulfide nitrogen 60+ 40g / t, pine oil 60+30g / t, roughing and sweeping for a total of 8 minutes to obtain antimony-gold mixed concentrate containing 11.25% antimony and 38g / t gold, which was carried out in a 0.5-liter flotation machine for 3 After the second refinement, 4.5g of antimony concentrate was obtained, the antimony grade was 41.33%, the recovery rate was 71.53%, the gold ...

Embodiment 2

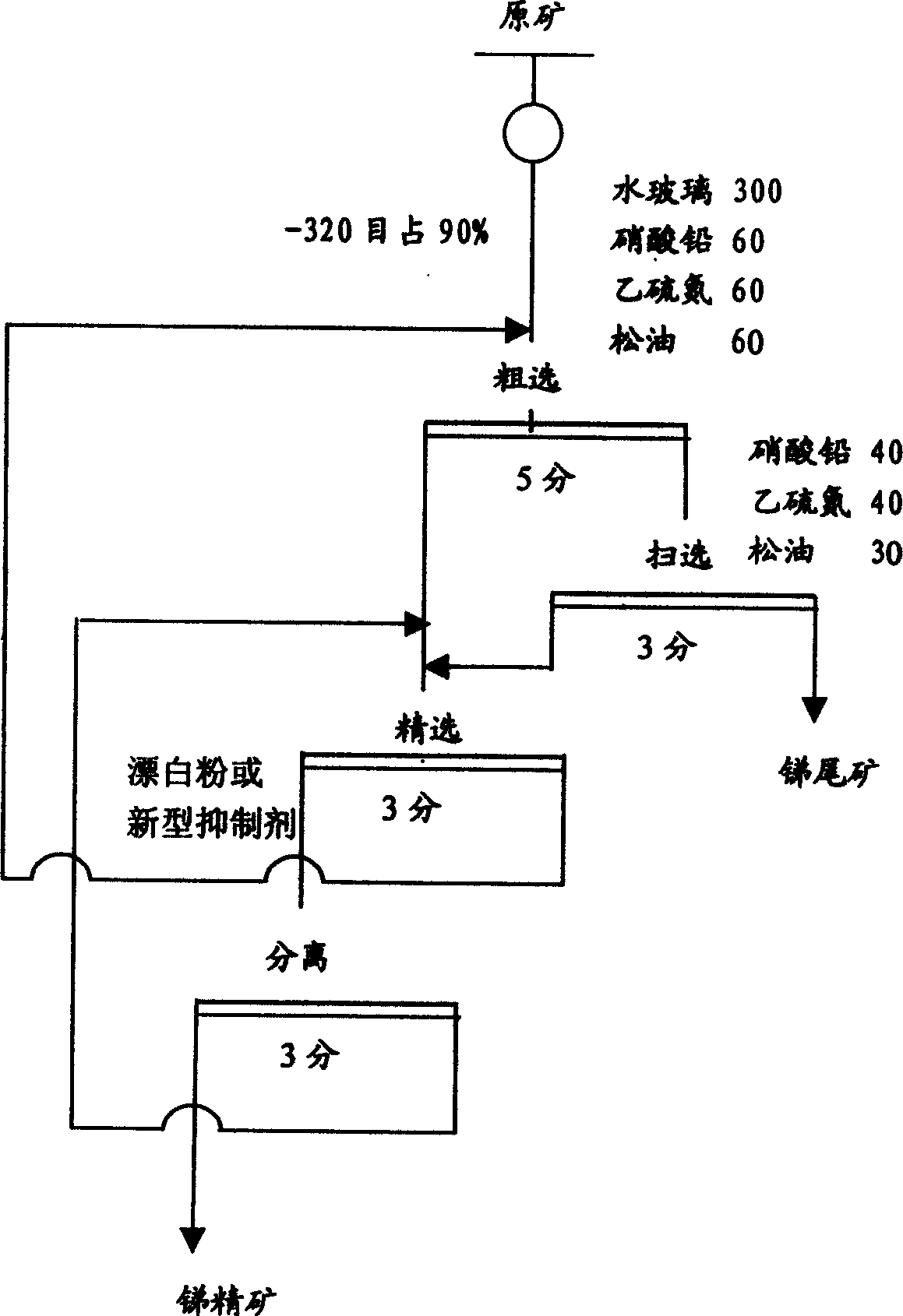

[0015] Add bleaching powder 1000g / t to antimony-gold mixed concentrate to carry out conventional separation test, the process flow is detailed in figure 2 .

[0016] Put 500g of ore containing 4.8g / t gold and 0.52% antimony into the laboratory-type ore grinding machine, the size of the grinding machine is Φ200×240mm, the grinding concentration is 60%, the grinding time is 8 minutes, and the grinding fineness reaches - 43μm accounts for 90%. The finely ground pulp is used in a laboratory-type flotation machine with a specification of 1.5 liters, and 300g / t of water glass, 60+40g / t of lead nitrate, 60+40g / t of ethyl disulfide, pine Oil 60+30g / t, roughing and sweeping for 8 minutes to obtain antimony-gold mixed concentrate containing 11.25% antimony and 38g / t gold, concentrate once in 0.5 liter flotation machine and add 1000g of bleaching powder / t for 1 separation, the time is 8 minutes, 3.9g of antimony concentrate is obtained, the antimony grade is 39.45%, the recovery rate ...

Embodiment 3

[0018] Add 200g / t of trichloroisocyanuric acid proposed by the present invention in antimony-gold mixed concentrate and carry out separation test as ore dressing inhibitor, its technological process is detailed in figure 2 .

[0019] Put 500g of ore containing 4.8g / t gold and 0.52% antimony into the laboratory-type ore grinding machine, the size of the grinding machine is Φ200×240mm, the grinding concentration is 60%, the grinding time is 8 minutes, and the grinding fineness reaches - 43μm accounts for 90%. The finely ground pulp is used in a laboratory-type flotation machine with a specification of 1.5 liters, and 300g / t of water glass, 60+40g / t of lead nitrate, 60+40g / t of ethyl disulfide, pine Oil 60+30g / t, roughing and sweeping for 8 minutes to obtain antimony-gold mixed concentrate containing 11.25% of antimony and 38g / t of gold, which is purified once in a 0.5-liter flotation machine and then added with trichloride Isocyanuric acid 200g / t was separated once for 8 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com