Non-woven fabric and laminate and string using the same

A technology of non-woven fabrics and fabrics, applied in the direction of textile, fabric, textile and papermaking, can solve the problems of difficult thickness, thinning, deformation, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

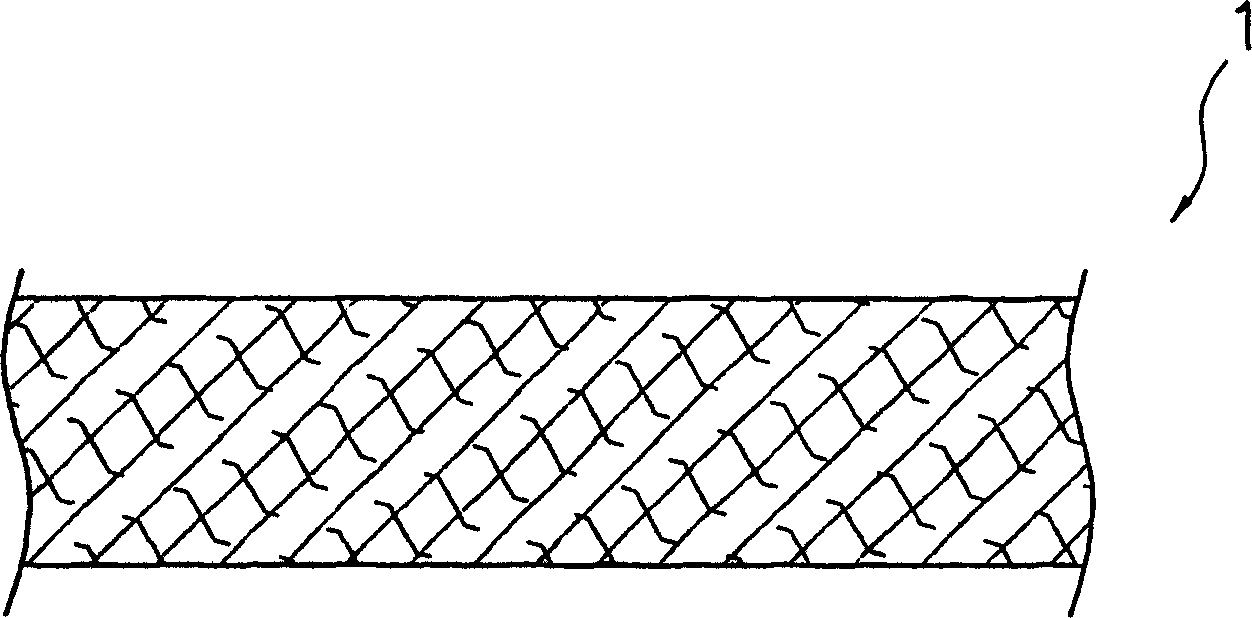

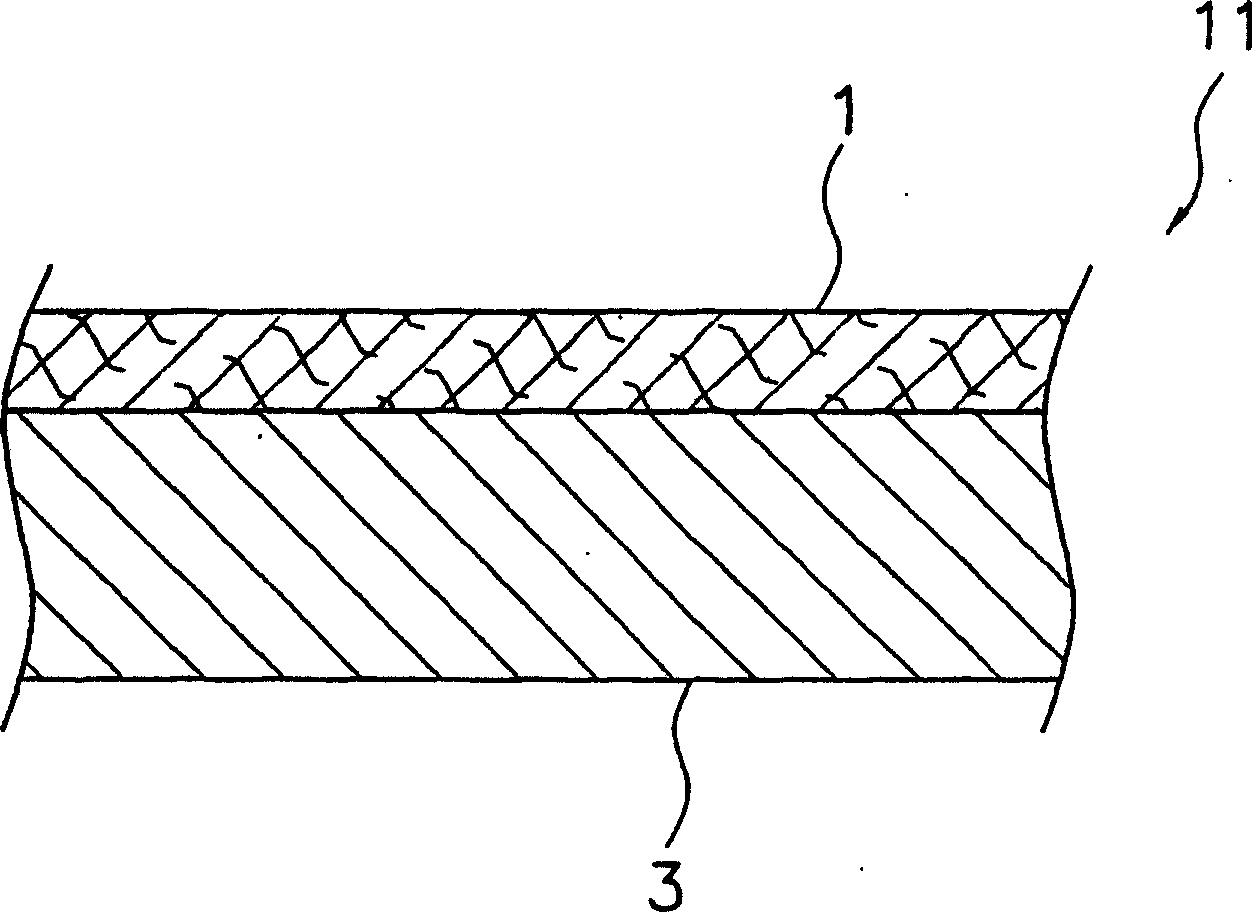

[0055] figure 1 The nonwoven fabric 1 according to the first embodiment of the present invention is shown.

[0056] This non-woven fabric 1 is mainly made of semi-fired PTFE fibers, which have a branched structure.

[0057] The fluororesin in this embodiment uses PTFE, but this PTFE can be either a separate polymer of tetrafluoroethylene (hereinafter referred to as TFE), or a small amount of perfluoroalkyl vinyl ester, etc. have been polymerized in TPE and undergo denaturation treatment. Denatured PTFE. In addition, in the present invention, unless otherwise specified, denatured PTFE is also referred to as PTFE.

[0058] In addition, copolymers of TFE and hexafluoropropylene (FEP), copolymers of ethylene and TFE (ETFE), copolymers of TFE and perfluoroalkyl vinyl ester (hereinafter referred to as PFA), etc., which can be melt-processed, can also be used. Resin to replace PTFE. These fluororesins may be used alone or in combination of two or more. These fluororesins have ex...

no. 2 Embodiment

[0096] The nonwoven fabric of the second embodiment of the present invention is the same as the nonwoven fabric of the first embodiment except that the resin of a part of the fluororesin fibers has welded points.

[0097] In the nonwoven fabric of the present embodiment, in the nonwoven fabric of the first embodiment, the temperature of at least a part of the fluororesin fibers in the nonwoven fabric is treated with pressure and heat at a temperature above its melting point. and obtained. However, when this temperature is too high, the fluororesin is excessively decomposed. For example, in the case of semi-fired PTFE, it is appropriate to treat at a temperature of 340°C to 360°C. Furthermore, in such a nonwoven fabric, it is preferable to heat only one side from the viewpoint of suppressing a change in the width of the nonwoven fabric due to heat shrinkage.

[0098] Specifically, for example, the nonwoven fabric can be passed between a metal roll heated to 340° C. to 360° C....

Embodiment 3

[0173] Embodiment 3 [rope]

[0174] With the width 8mm that obtains with specific example 2, the stretched workpiece of thickness 0.4mm, carry out the twist processing of length direction 1 turn / cm, process into about 1.3mm in outer diameter, the rope-like thing of total length about 400mm.

[0175] The strength obtained with this processing is as follows.

[0176] Tensile strength before twisting processing (test piece width 8mm, thickness 0.4mm)

[0177] Maximum point load: 30N, maximum point elongation 22%

[0178]Tensile strength after twisting processing (outer diameter of test piece is about 1.3mm)

[0179] Maximum point load: 60N, maximum point elongation 25%

[0180] By twisting the strip-like body, a rope-like body having a large tensile strength per unit weight is obtained.

[0181] In addition, this kind of rope can also be processed by firing, and the looseness of fibers can be improved by firing, so that a rope with high tensile strength can be obtained.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber length | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com