Method for preparing platinum catalytic electrode

A catalytic electrode and conductive glass technology, applied in the field of solar cells, can solve the problems of large amount of platinum-loaded Pt and low electrocatalytic reaction activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concentration in 250ml is 8.0×10 -4 K in mol / L 2 PtCl 6 Add 0.4 ml of sodium acrylate (molecular weight: 94) with a concentration of 1.0 mol / L to the aqueous solution as a protective agent, then add methanol as a reducing agent in a ratio of (1 / 1, V / V), and pass argon for 15 minutes. The mixed solution was refluxed at 90°C for 2 hours. After the mixed solution was cooled to room temperature, 1.2 ml of a mixed solution of dodecylmercaptan and toluene (1 / 1, V / V) was added, and ultrasonically dispersed for 10 minutes. The organic phase solution containing platinum Pt particles was separated and uniformly coated on tin dioxide SnO 2 The conductive glass surface was dried and sintered at 380°C to obtain a platinum-loaded Pt electrode.

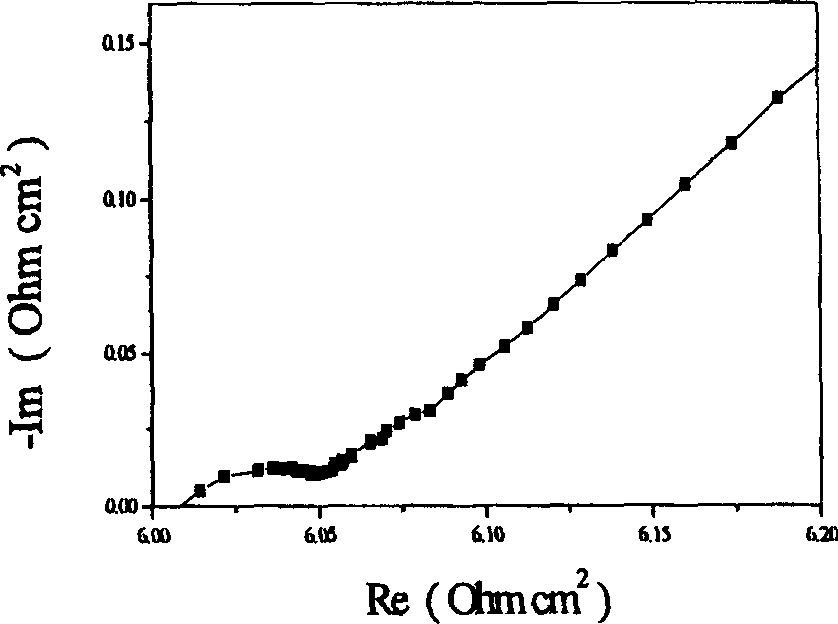

[0020] The amount of platinum-loaded Pt on the conductive glass, using aqua regia to dissolve platinum Pt, and then measure its content with plasma emission spectrometry (ICP), the platinum-loaded Pt amount of the prepared platinum-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com