Method for reclamation and utilization of oil refining sewage

A technology for oil refinery sewage and filter materials, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult removal of ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

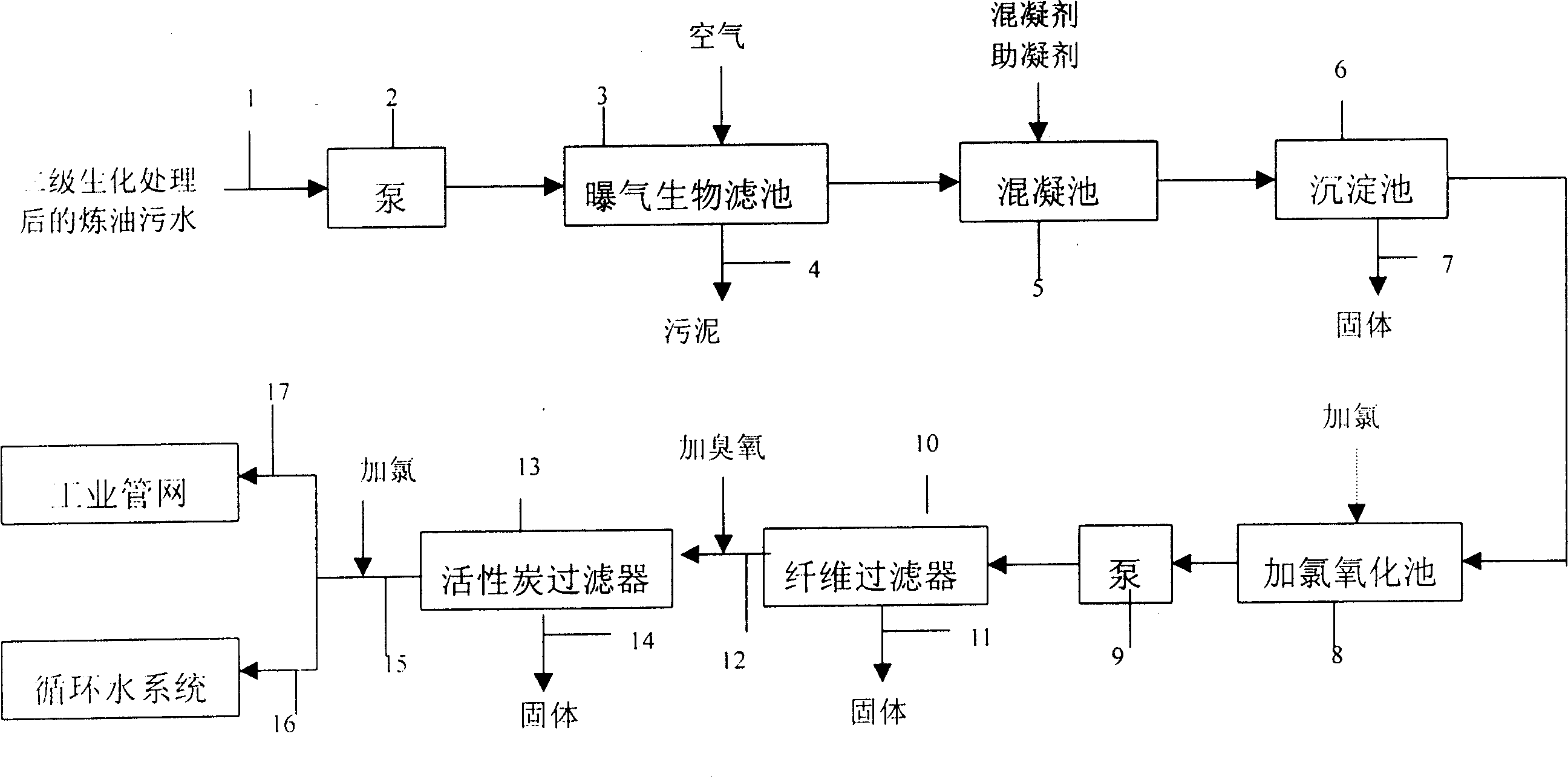

[0032] The process shown in the attached figure is used to treat the refinery sewage after secondary biochemical treatment, and the control conditions are as follows:

[0033] Biological aerated filter: the filter material is volcanic rock with a particle size of 3-10mm, the inflow of sewage is 10 tons / hour, and the ammonia nitrogen load of the filter is 0.08-0.10kg / (m 3 .d), dissolved oxygen 3-5mg / L, aeration intensity 0.16N m 3 / m 2 .min.

[0034] Coagulation tank: add coagulant and coagulant aid, the coagulant is polyaluminum chloride, the dosage is 15mg / L, the coagulant aid is cationic polyacrylamide, the dosage is 1mg / L, water is in the mixing tank The residence time of the coagulation pool is 30min.

[0035] Sedimentation tank: surface load is 0.80m3 / m 2 .h, the residence time is 3.5h.

[0036] The residence time of the chlorine addition and oxidation tank is 60 minutes, and the dosage of chlorine is determined according to the concentration of ammonia nitrogen in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com