Rubber automobile synchronous belt and its producing method

A manufacturing method and technology of timing belts, which are applied to belts, other household appliances, household appliances, etc., can solve the problems of complex manufacturing process, poor performance of timing belts, and short service life, and achieve simple manufacturing process, stable performance, and cost of use. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

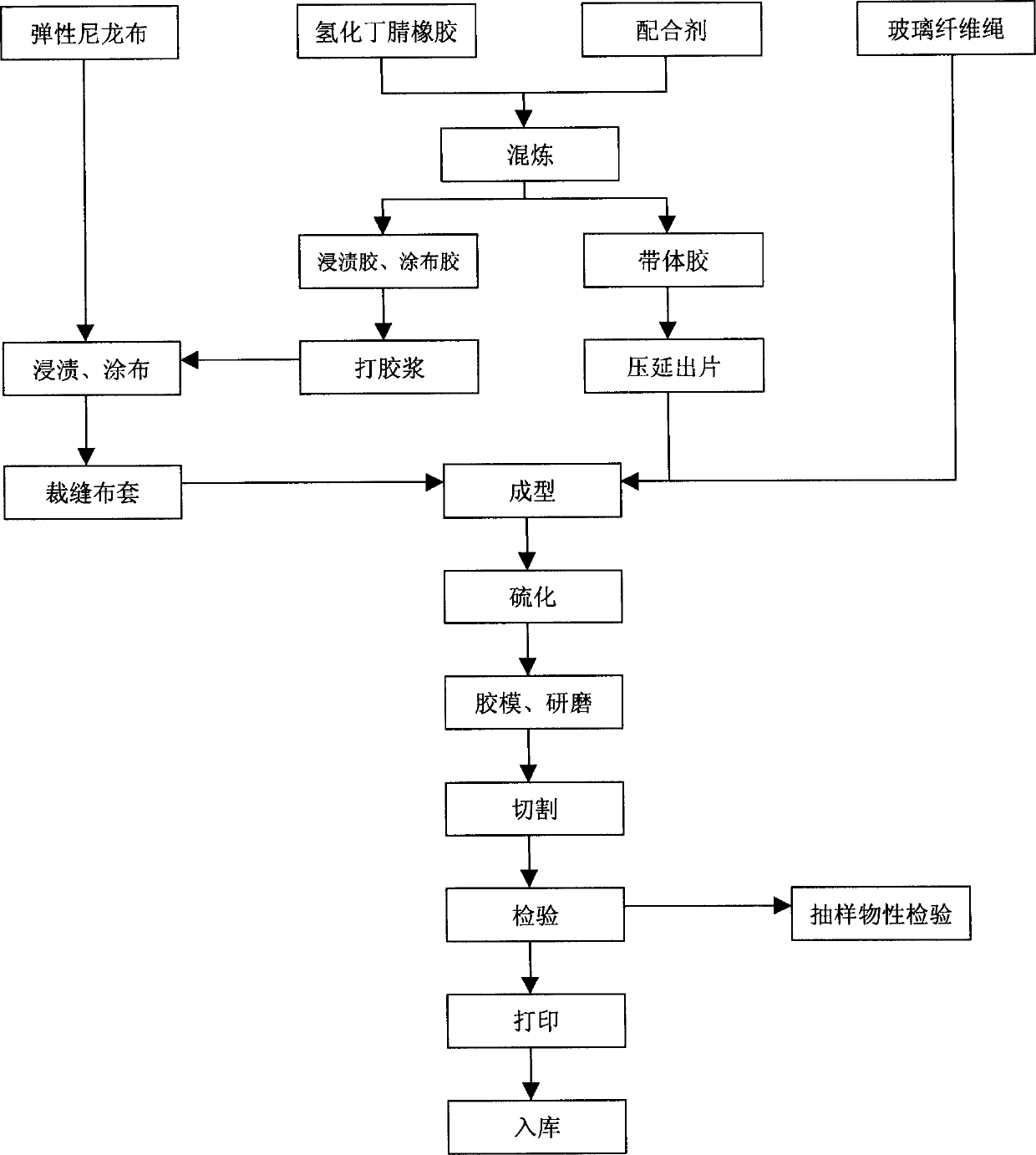

Method used

Image

Examples

Embodiment 1

[0040] The invention adopts high-strength elastic nylon cloth as the synchronous belt tooth bread cloth. As a synchronous toothed belt covering cloth, in addition to high strength, it also has good wear resistance and latitudinal elongation and good tooth filling ability, and also requires good bonding force with the belt body, so it must be Elastic nylon cloth for surface treatment.

[0041] 1. Treatment of high elastic nylon cloth:

[0042] Firstly, the nylon cloth is impregnated with hydrogenated nitrile rubber thin glue (the glue concentration is 15-17%), so that the impregnated glue can fully penetrate into the fabric fibers, and an appropriate amount of M300 isocyanate is added to the above treatment solution (thin glue) Tackifier. Then carry out thick glue coating treatment (concentration is 24-26%), make the surface of the fabric attach a certain amount of glue layer, then carry out heating and drying treatment to the nylon cloth with glue layer, and its temperature ...

Embodiment 2

[0059] Embodiment 2: main raw material rubber and compounding agent, its composition ratio (calculated by weight percentage).

[0060] In this embodiment, firstly, the high elastic nylon cloth is subjected to surface treatment, using the treatment method in Example 1. The main raw materials, compounding agents and their formula ratios selected in the rubber mixing process are as follows: the main raw material rubber is hydrogenated nitrile rubber: 55, zinc oxide: 2.7, stearic acid 0.55, anti-aging agent: 2.2, semi-reinforced carbon Black: 30.2, Softener: 5.5, Sulfur: 0.42, Accelerator: 2.7. The above-mentioned rubber and compounding agent also adopt the process steps in Example 1 in the rubber mixing process. According to the process conditions of hydrogenated nitrile rubber and compounding agent which are difficult to disperse during mixing, a staged mixing method is designed in which the compounding agent is gradually added in batches, thus forming a colloidal sheet and the...

Embodiment 3

[0062] In the embodiment of the present invention, the treatment method of the high-stretch elastic nylon cloth is also carried out by using the treatment method in Examples 1 and 2.

[0063] Main raw material rubber and compounding agent, their composition ratio (by weight percentage).

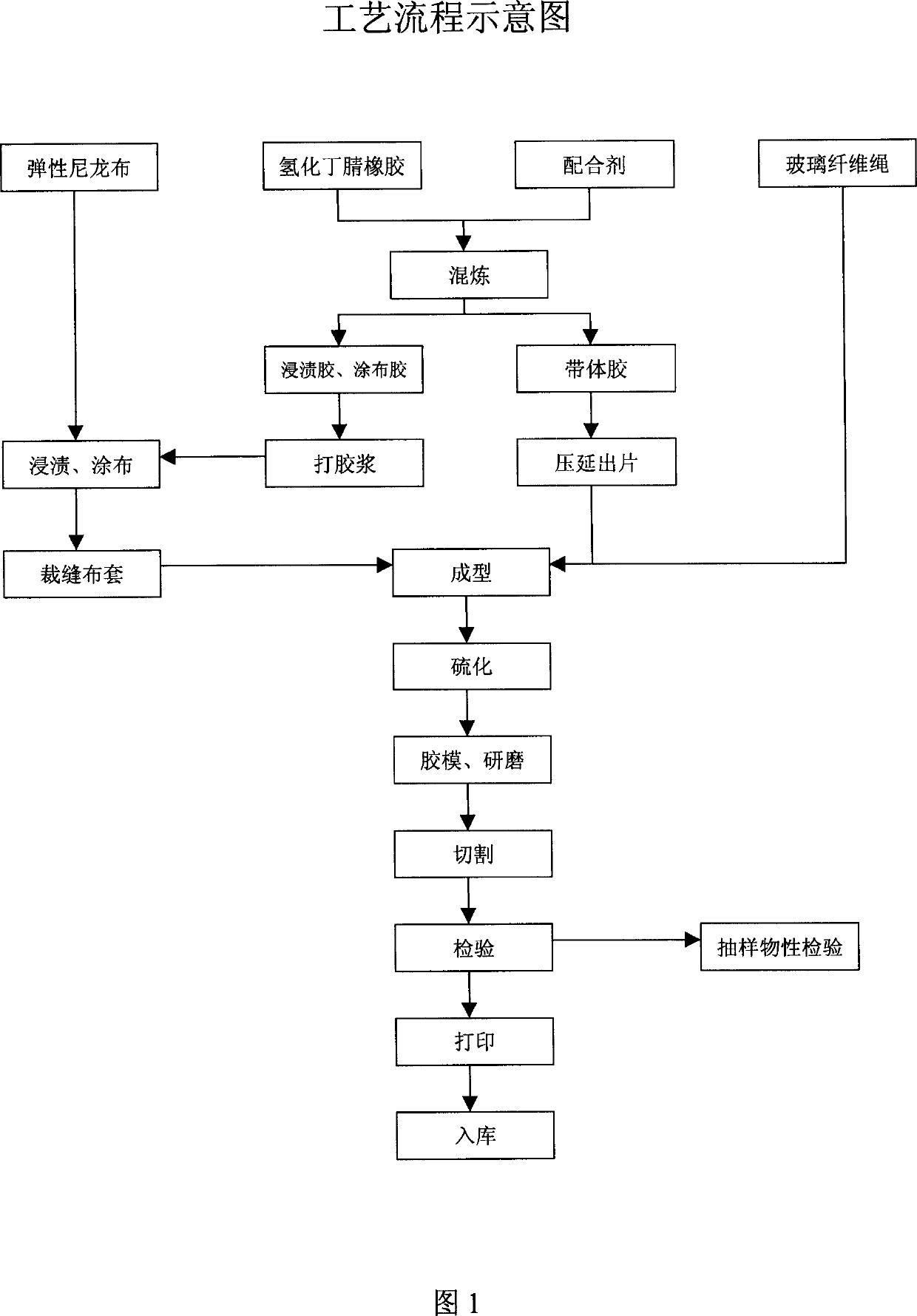

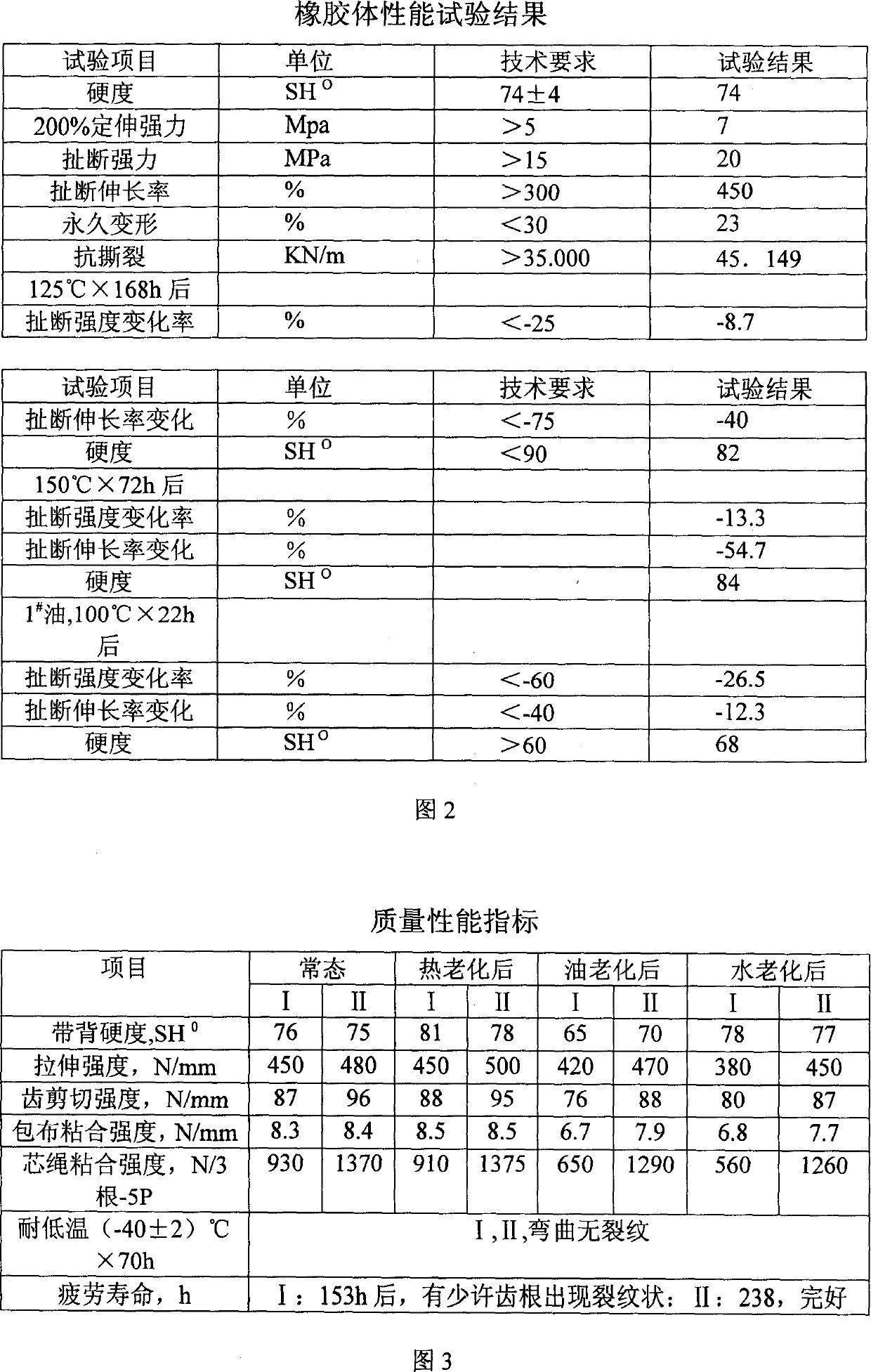

[0064] Get hydrogenated nitrile rubber: 53, zinc oxide: 2.18, stearic acid: 0.57, high temperature resistance, ozone resistance anti-aging agent: 2.3, semi-reinforcing carbon black: 31.8, softener: 5.6, sulfur: 0.45, accelerator: 2.8. Process steps and process conditions thereof such as rubber mixing (two-stage mixing) adopted in embodiment 1.2, calendering with colloid, molding, vulcanization, demoulding, grinding, cutting, inspection (sampling physical property inspection) and the like. Made to meet the quality and performance indicators achieved by the performance of the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com