Directly and fast forming method and device for polymetal based on welding amassed

A molding device and multi-metal technology, applied in the field of manufacturing, can solve the problems of difficult popularization and application, unsatisfactory parts organization compactness and mechanical properties, expensive equipment costs and operating costs, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

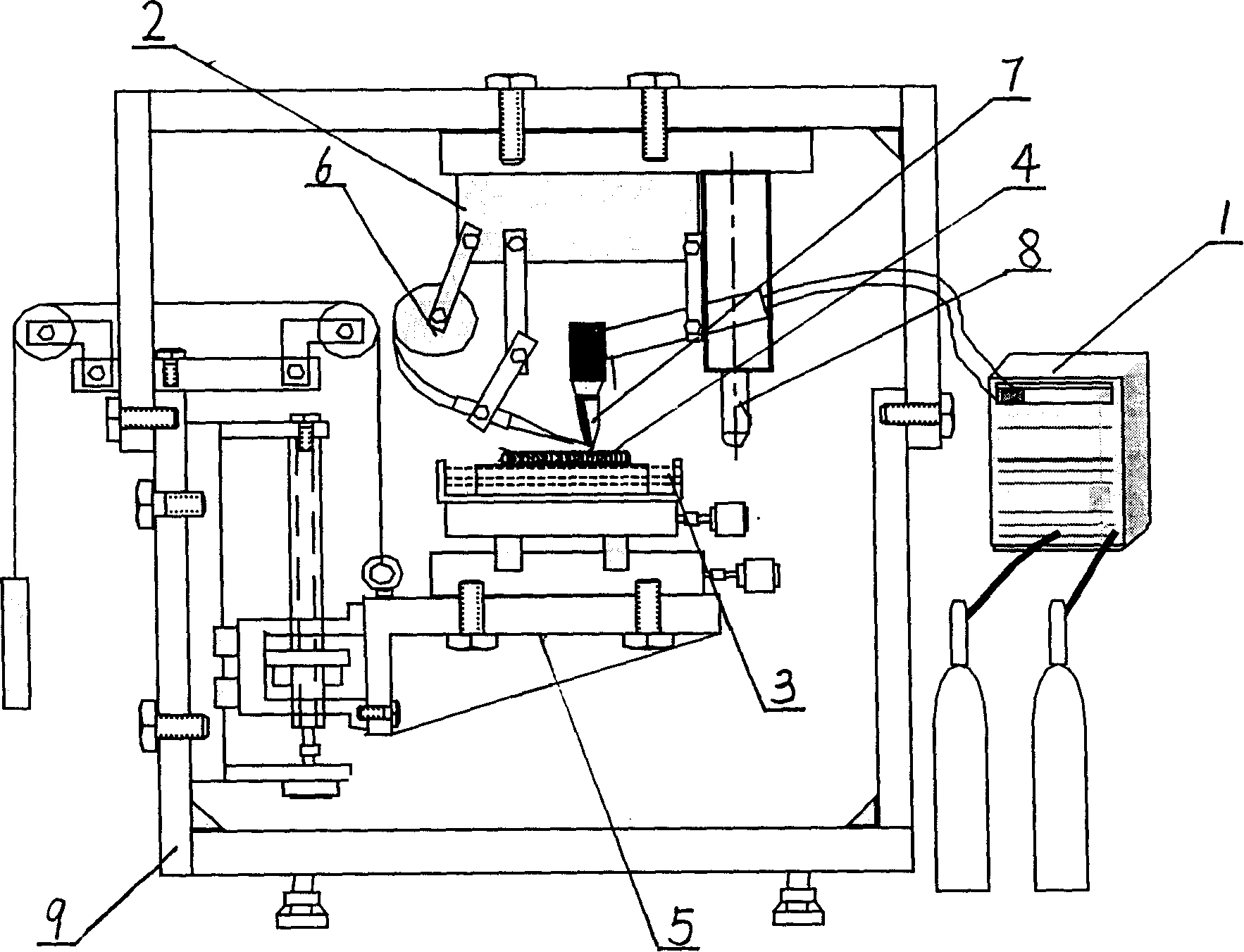

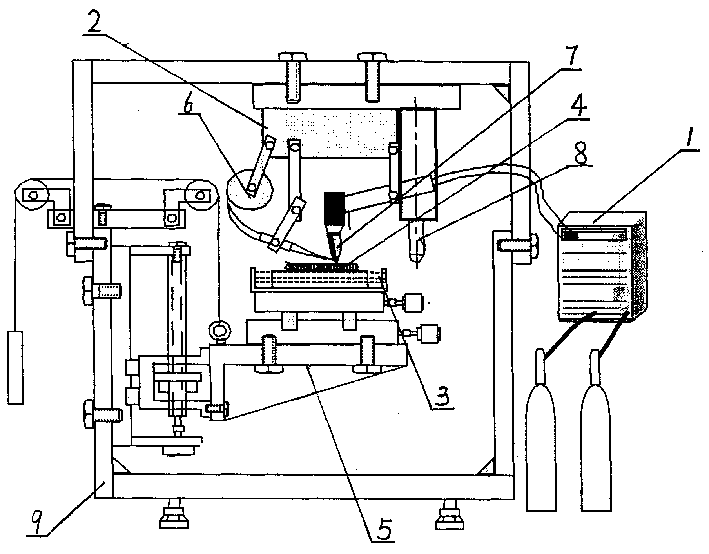

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] see figure 1 , the present invention includes frame 9. The three-dimensional workbench is fixed on the lower end of the frame 9 through a vertical plate, and the verticality of the vertical plate can be adjusted. The whole three-dimensional workbench 5 is equipped with a counterweight to reduce the influence of gravity and the bending effect on the vertical plate when the workbench 5 moves up and down. . The three-dimensional workbench 5 can carry out X-Y axis linkage and Z-axis lifting movement under the control of the numerical control system. The linkage of the X-Y axis mainly completes the formation of a single line and layers in the stacking process and the feed movement relative to the high-speed milling head 8 during layer processing. The Z-axis movement mainly completes the layer-by-layer accumulation and the Z-direction feed movement during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com