Magnetostrictive driver with water-cooled plant and the forming method of its screw flat tube

A magnetostrictive and water-cooling device technology, applied in the mechanical field, can solve the problems of increased volume of the driver, inapplicability, and difficulty in obtaining an ideal compensation effect, and achieves the effect of fewer processing links and a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

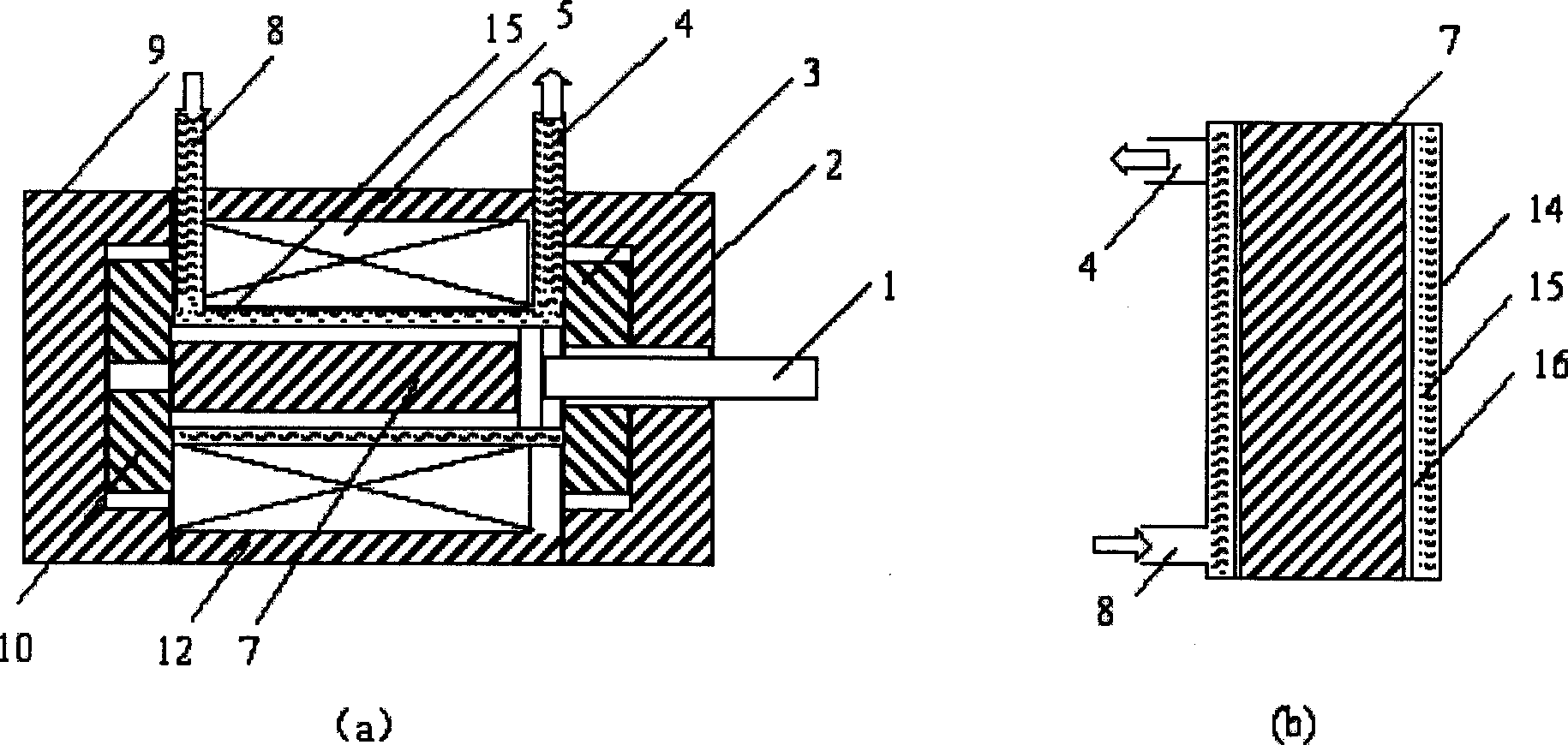

[0033] At first process the spiral flat tube 6 with the forming method of the spiral flat tube used for the magnetostrictive driver with forced water cooling device of the present invention, as Figure 5 As shown, the metal round tube adopts a copper tube with a diameter of 5mm, and the processing steps are as follows:

[0034] 1) Using an ordinary lathe, clamp the cylindrical mandrel 18 with the positioning hole 23 with the chuck 17 and support it with the neck tip 19;

[0035] 2) Insert one end of the copper tube to be processed into the positioning hole 23 on the mandrel 18, replace the knurled roller with a common bearing 21 and install the rolling tool 20 installed on it through the pin shaft 22 on a common lathe on the tool rest, and adjust the position of the tool rest so that the bearing 21 will squeeze the copper tube near the positioning hole 23; Make the knife rest move according to the mode of processing the left-handed thread, and complete the extrusion molding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com