Plate heat exchanger

A plate heat exchanger, along the plate technology, applied in the direction of indirect heat exchanger, heat exchanger type, heat transfer modification, etc., can solve the problem that it is difficult to fully ensure pressure sealing, etc., to achieve good heat exchange performance, plate heat exchanger Effect of compact heater and improved pressure tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

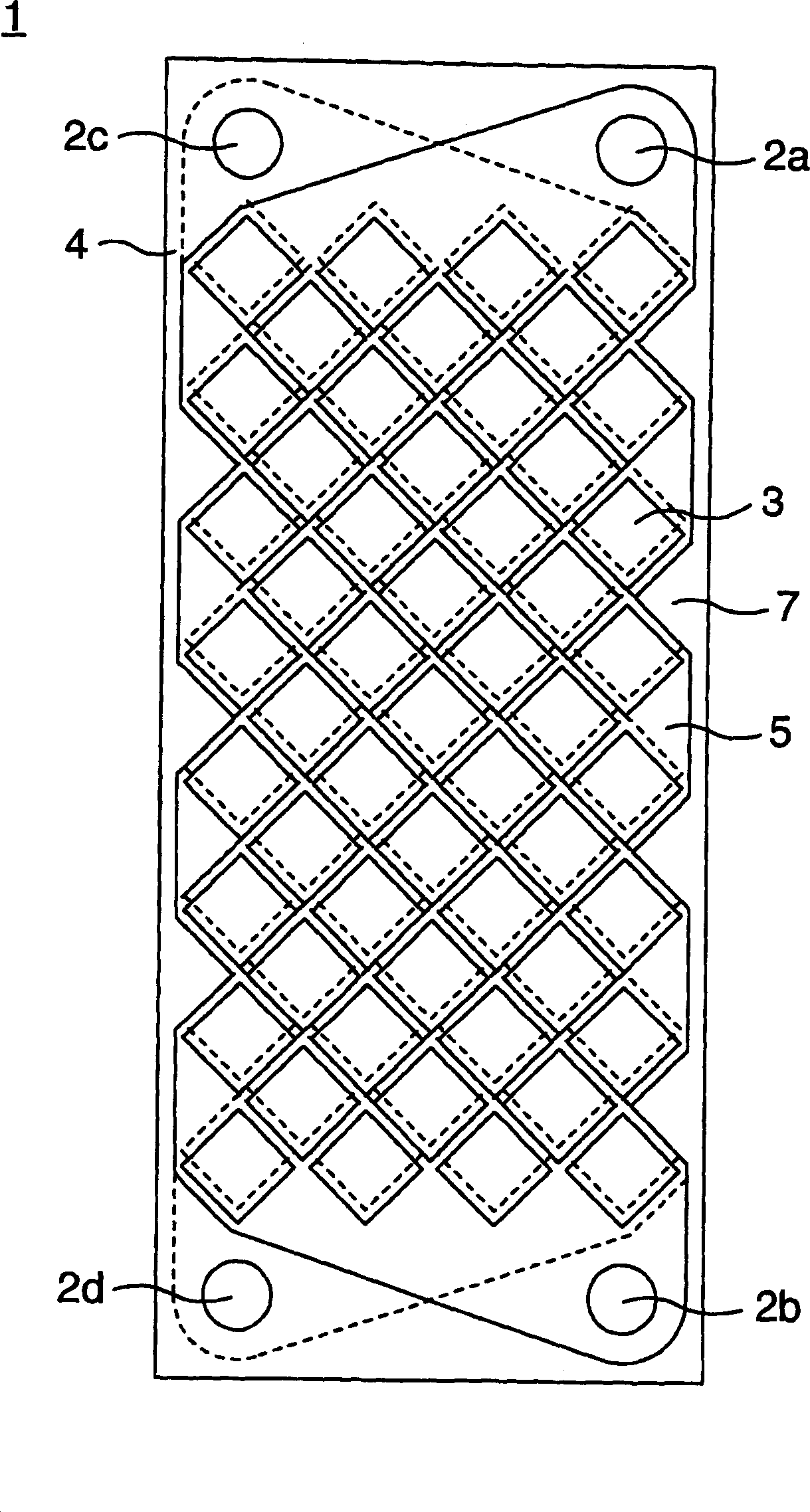

[0019] The following will refer to Figures 1 to 3 Embodiments of the present invention are described. figure 1 is a plan view showing the plate 1 constituting the plate heat exchanger, and figure 2 Yes (when from figure 1 When viewed from the back side) is a plan view showing a state when the boards 1 are turned upside down alternately so as to be stacked on top of each other.

[0020] The plate 1 is formed by press working of a thin metal plate and has four openings 2a to 2d. Only two openings 2 a , 2 b define one flow channel in the plate 1 , and this flow channel is separated by the sealing portion 4 . Pyramidal heat transfer surface elements 3 are formed on the plate 1, the heat transfer surface elements 3 define peaks or valleys along the thickness direction of the plate, and the upper end portion 6 of the heat transfer surface elements has a flat top, that is, the surface The element 3 is in the shape of a truncated quadrangular pyramid. The pyramidal heat transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com