Protective treatment method for oil sucking rod, oil pipe and sleeve used specially for oil field

A technology for sucker rods and oil pipes, which is applied in the field of protective treatment of metal pipes and rods, can solve problems such as easy peeling of pick-up pumps, temporary solutions, and poor quality, and achieve considerable economic benefits, cost reduction, and strong pertinence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

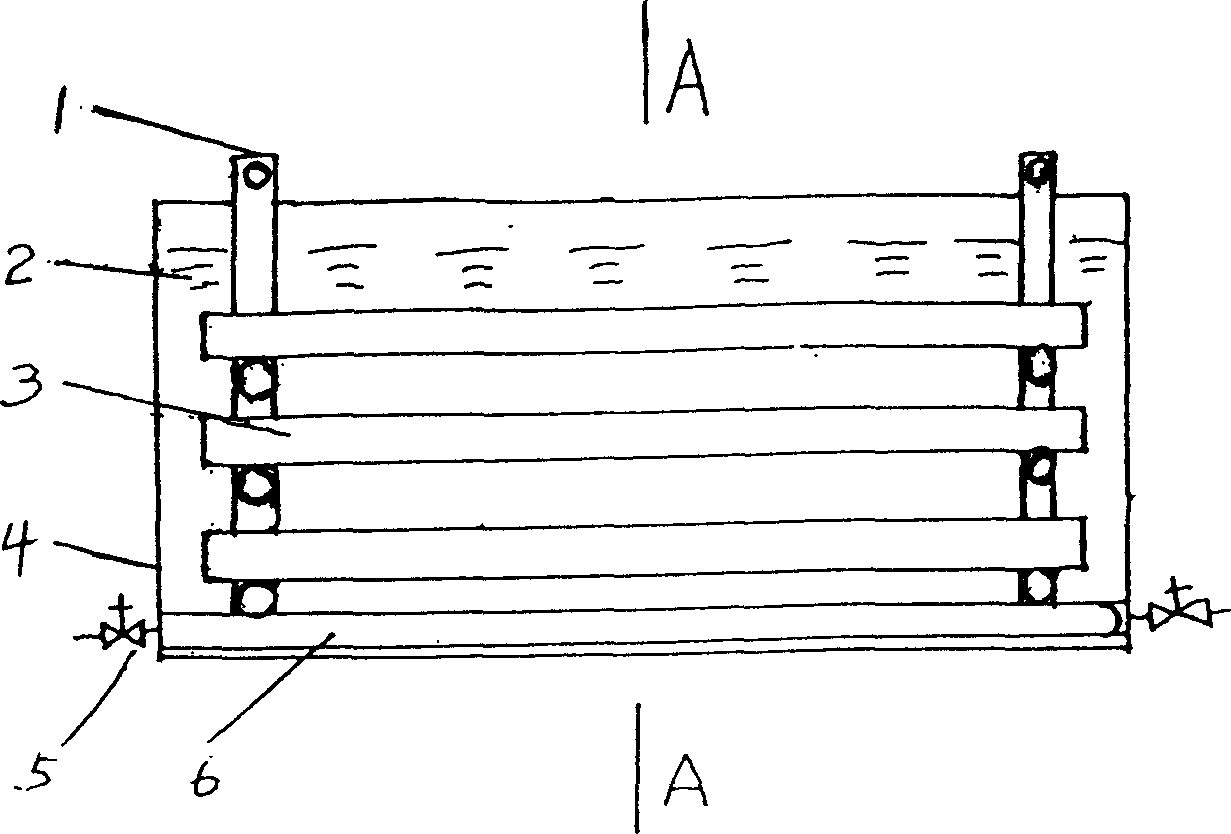

[0047] In this example, oil removal → rust removal → surface activation → anodic plating → multi-functional plating process is adopted for the oil pipe to obtain the following figure 1 The oil pipe with a composite layer thickness of 10 microns in the coating structure has an amorphous coating, a friction coefficient of 0.1-0.2, a bright black surface, a phase transition temperature of 342.4°C, an elongation of 3-6%, and no pinholes. Acid, alkali and salt immersion resistance, other properties are shown in Table 1-Table 4.

example 2

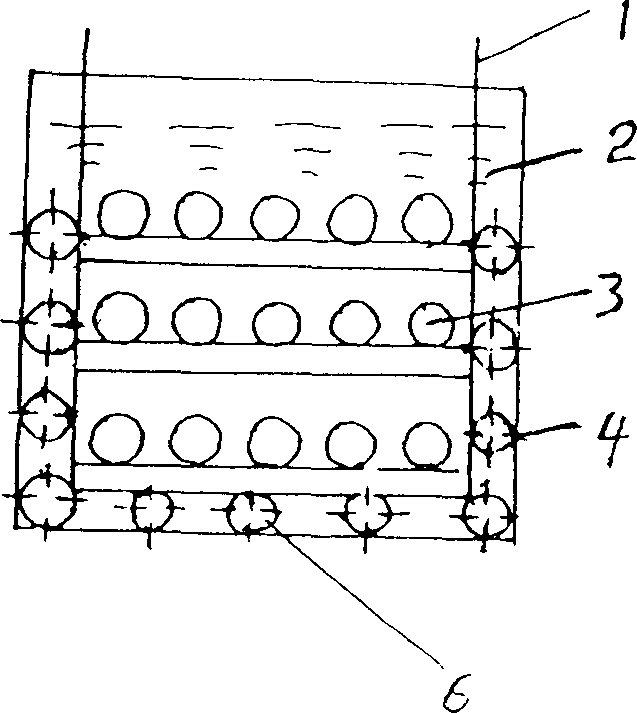

[0049] In this example, oil removal→rust removal→inner wall spraying→outer wall spraying is adopted for the oil pipe. Both the inner and outer walls are sprayed twice, and the spray paint needs to be dried and solidified after each spraying, and the following is obtained: figure 2 The shown oil pipe with coating structure, the spray paint used is petroleum resin.

[0050] The properties of the oil pipe are: paint film thickness 65μm, hardness (HV) 300, flexibility 1mm, impact resistance 50kg / cm 3 , acid resistance: no change in immersion in 80% sulfuric acid for 100 hours, alkali resistance: no change in immersion in 10% sodium hydroxide for 106 hours, salt resistance: no change in immersion in 30% brine for 100 hours .

example 3

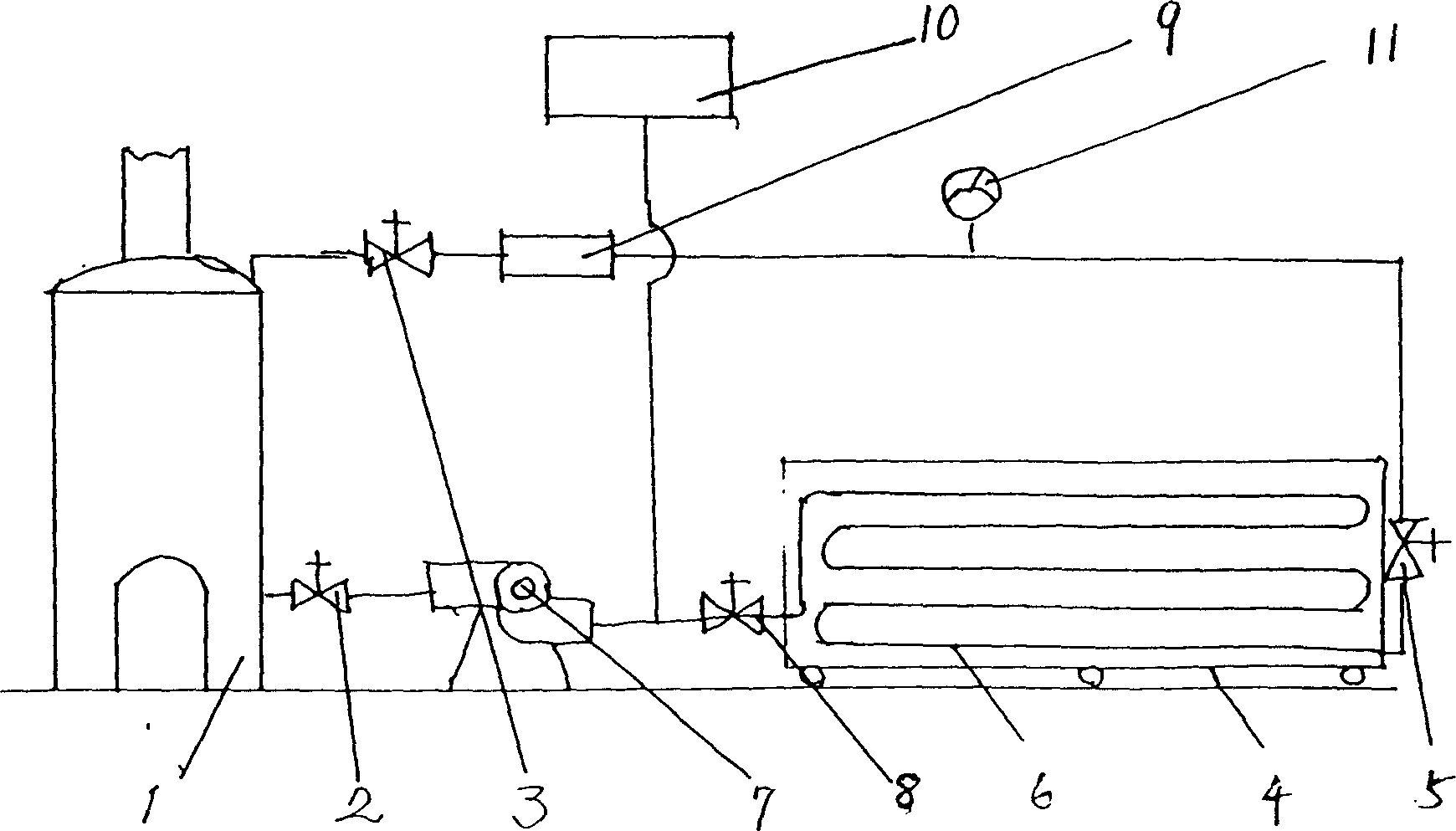

[0052] In this example, oil removal→rust removal→surface activation→inner wall anodic plating→inner wall multi-functional plating→outer wall spraying→drying and curing spraying process is adopted for the oil pipe, and the following is obtained: image 3 Oil pipe with inner wall coating and outer wall spray coating structure. The outer wall is sprayed twice, and the spray paint used is polyester resin, and its performance: the outer wall performance is the performance of Example 2, and the inner wall is the performance of Example 1.

[0053] Alloy composition

[0054] PTFE content (%)

[0055] PTFE content (%)

[0056] PTFE content (%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com