Method for producing bonding wafer

A technology for laminating wafers and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., and can solve problems such as large interface erosion, insufficient mass production technology, and dust generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~3

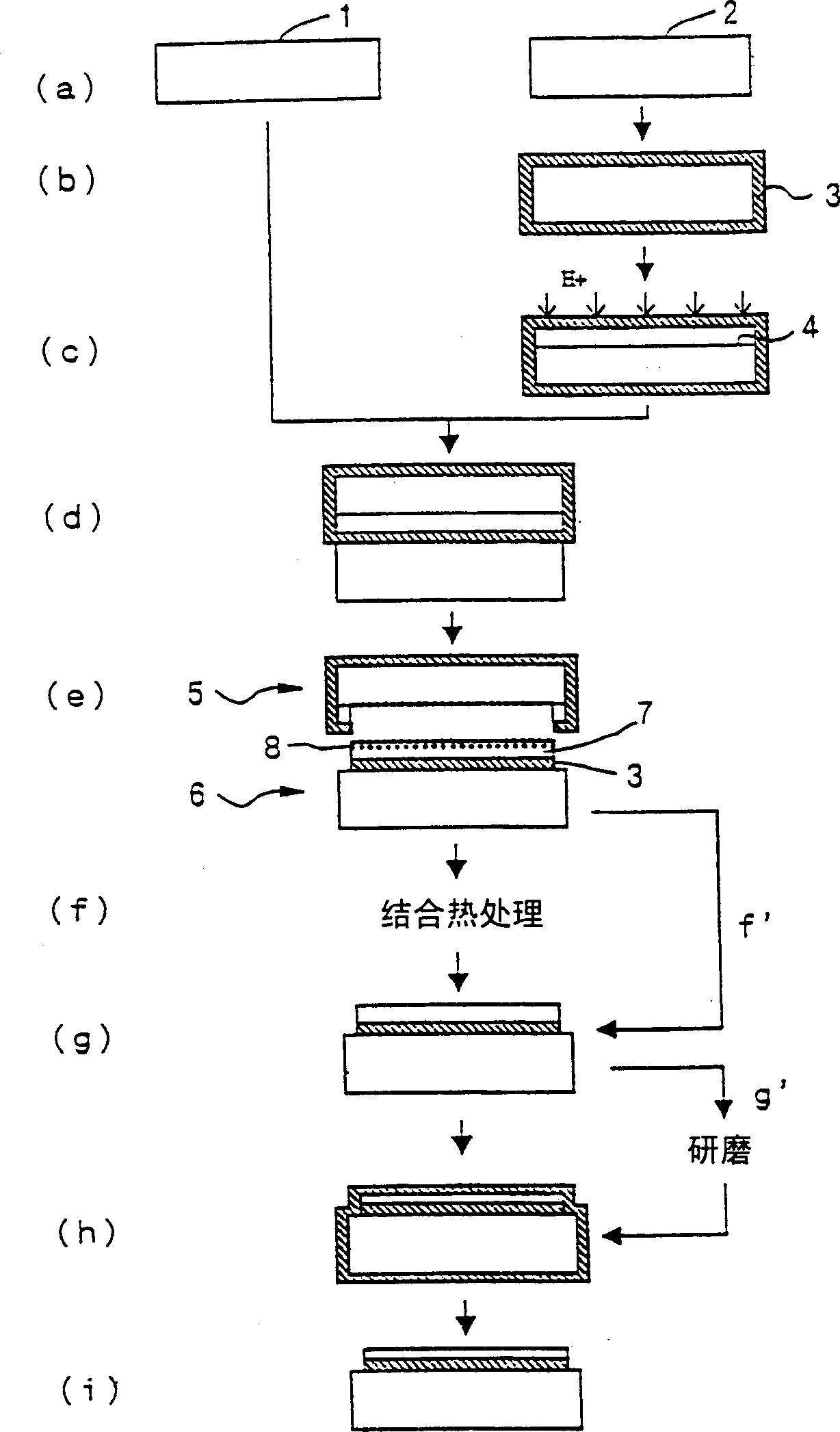

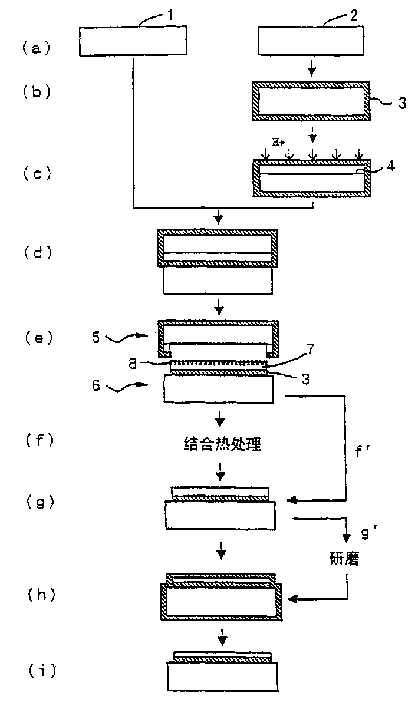

[0050] In the crystal orientation (100) produced by the CZ method, a silicon single crystal ingot whose conductivity type is p-type and a resistivity of 20G·cm is sliced, and the ingot is processed to produce a silicon mirror wafer with a diameter of 200mm . Divide these into bonded chips and base wafers, according to figure 1 In the steps shown in (a) to (i), an SOI wafer is manufactured by using the ion implantation lift-off method of the present invention.

[0051] First, follow the figure 1 In (a) to (e), the bonded wafer 2 is peeled off to obtain an SOI wafer 6 . At this time, the thickness of the buried oxide film 3 is 400 nm, and main conditions such as implantation of other ions are as follows.

[0052] 1) Ion implantation conditions: H + Ions, implantation energy 90keV,

[0053] Injection line volume 6.5×10 16 / cm 2

[0054] 2) Stripping heat treatment conditions: N 2 Under air environment, 500℃, 30 minutes,

[0055] As described above, altho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com